Low-cost laser sintering 3D printer based on single chip microcomputers

A 3D printer and laser sintering technology, applied in the field of 3D printing, can solve the problems of low printing accuracy, difficult operation, and low printing efficiency, and achieve the effects of improving printing accuracy, compact overall structure, and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

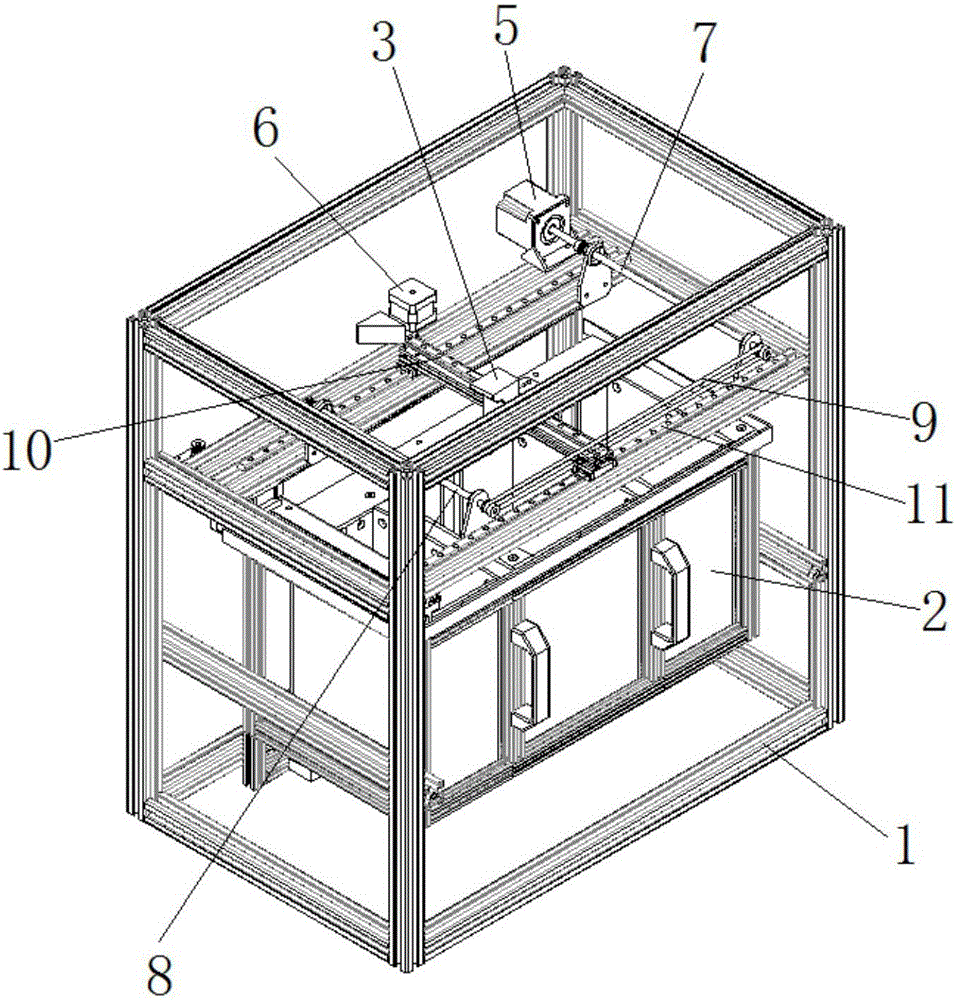

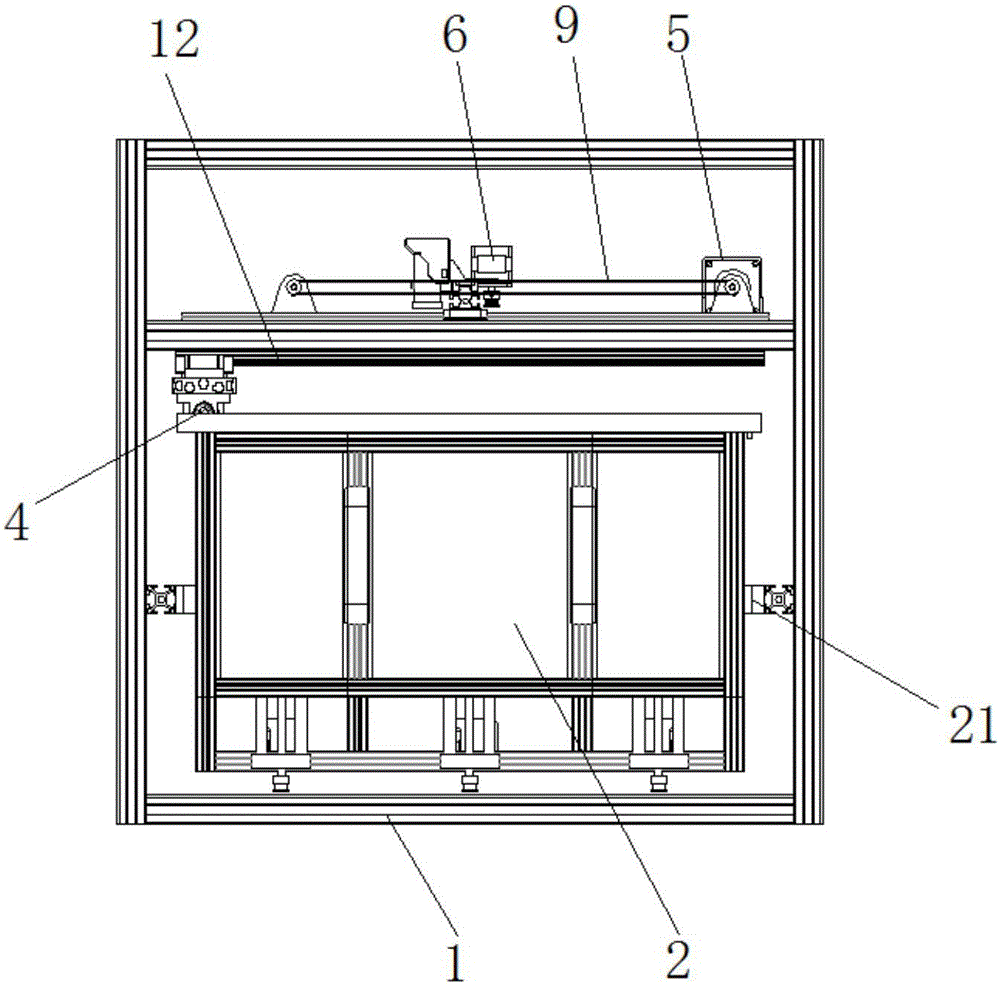

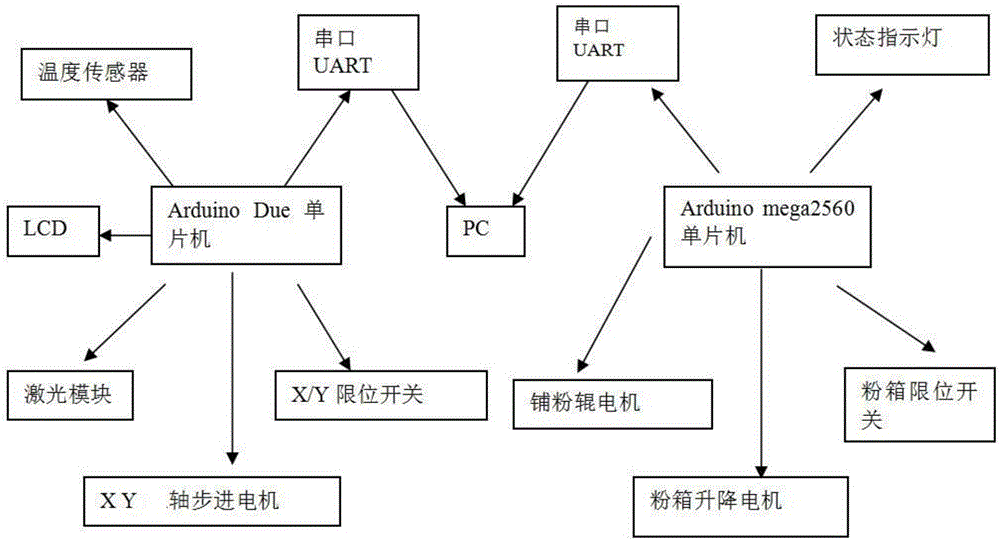

[0019] Such as figure 1 with figure 2 A low-cost laser sintering 3D printer based on a single-chip microcomputer is shown, including a frame 1, and also includes a modular powder box 2, a laser module 3, a powder spreading roller 4, an X-axis stepping motor 5, and a Y-axis stepping motor 6 and the control system, the modularized powder box 2 is movably installed on the frame 1 through the powder box track 21 with self-locking function, and the X-axis stepping motor 5 is installed and fixed on the top of the frame 1 and on its output shaft A transmission shaft 7 is connected through a coupling, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap