Packaging cover plate of sensitivity-strengthened electric field sensor and packaging method

A technology of electric field sensor and packaging cover plate, which is applied in the direction of electrostatic field measurement, electric solid devices, instruments, etc., can solve the problems of sensor sensitivity and resolution reduction, effective sensing structure area reduction, sensor sensitivity attenuation, etc., to improve the environment Adaptability, reduced relative temperature drift, and enhanced ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

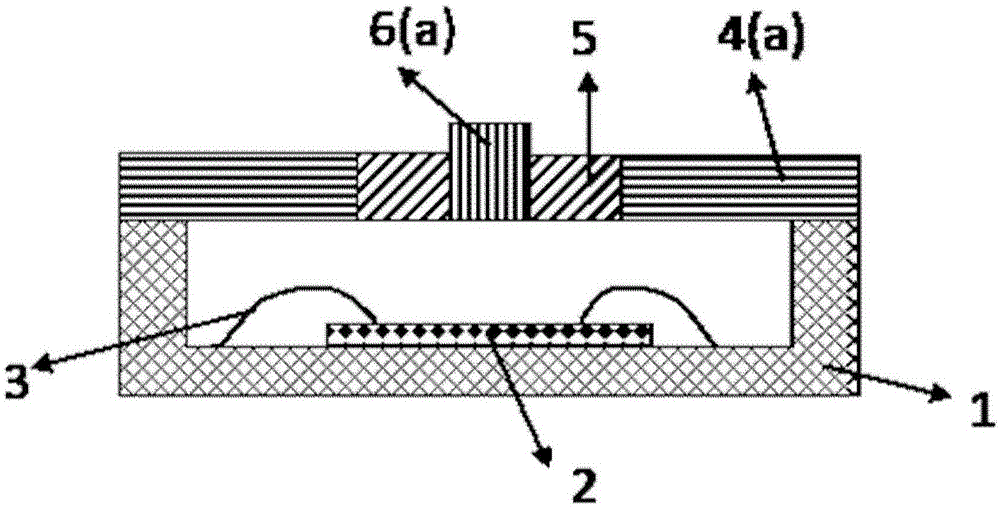

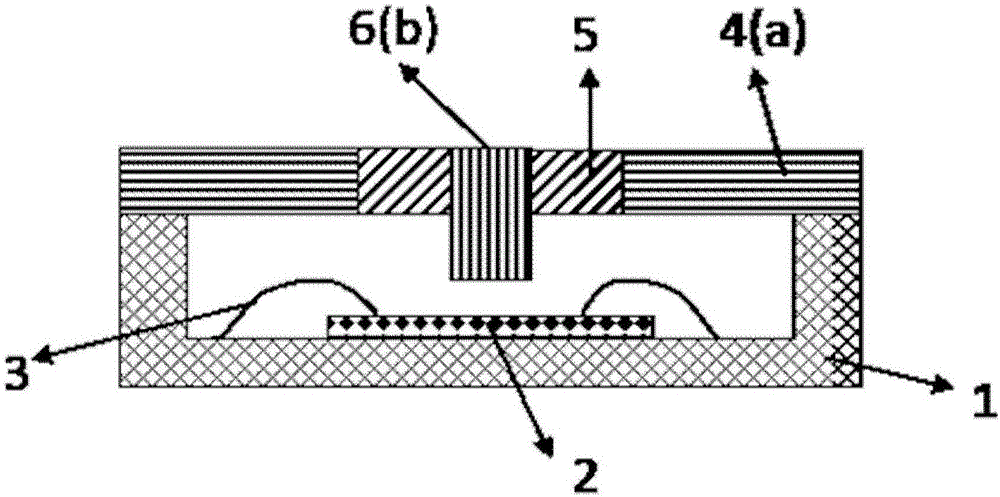

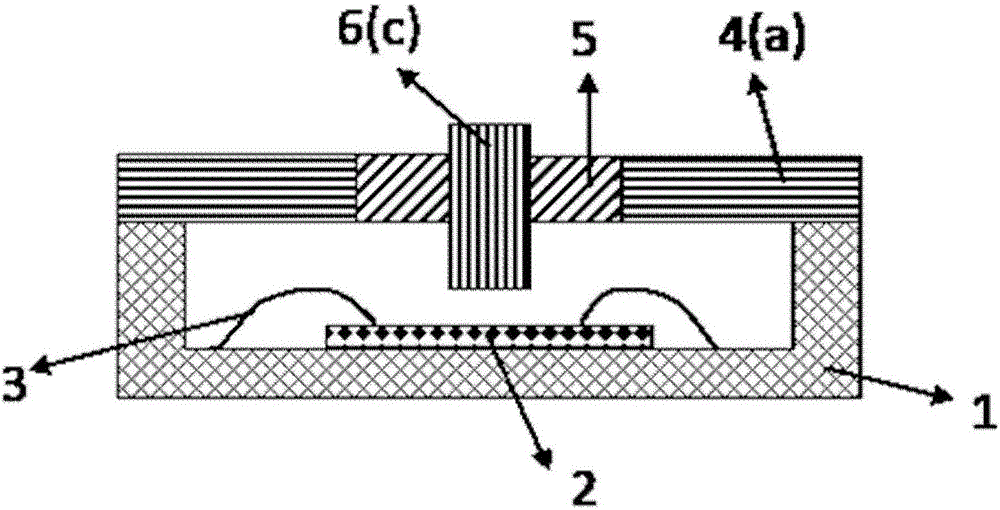

[0073] According to the above-mentioned packaging method and the packaging structure in which the inner core on the packaging cover plate is simultaneously convex and convex described in the specific embodiment 3, the present invention correspondingly proposes a specific embodiment 10 of the packaging method, and the steps specifically include:

[0074] Step 1: Prepare the packaging cover plate;

[0075] First, the processing of the edge 4(a) of the cover plate: process the edge 4(a) of the sheet-shaped cover plate by die stamping. Metal materials suitable for stamping include low carbon steel, stainless steel, aluminum and aluminum alloys, copper and copper alloy, etc., preferably iron-cobalt-nickel alloy. Electroplating treatment is carried out after stamping to prevent rust and oxidation. The coating is generally zinc, nickel, gold and other metals or their alloys, preferably gold coating. Holes of preset shapes such as circles and squares are reserved inside the edge 4 (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com