Side anode vacuum channel nanogap triode and preparation method thereof

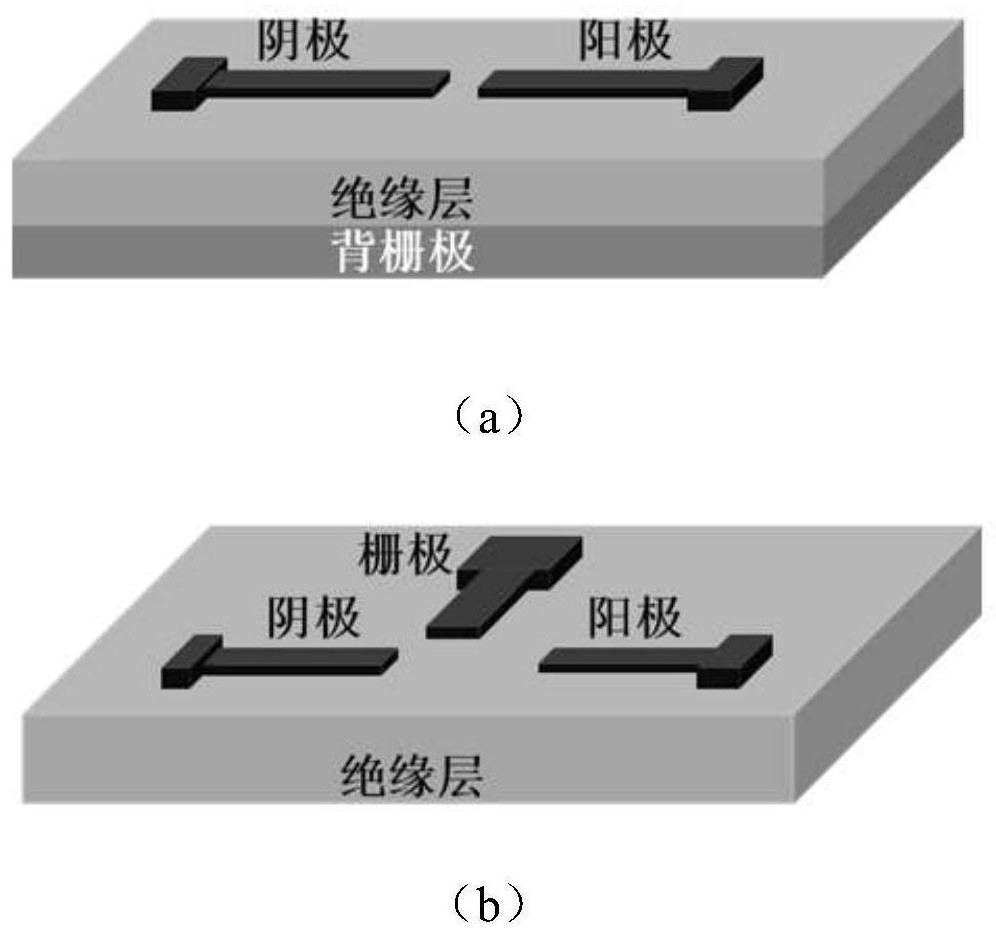

A nano-gap, triode technology, applied in cold cathode manufacturing, electrode system manufacturing, single discharge channel tube, etc., can solve the problems of difficult to achieve miniaturization, light weight and integration, bulky and bloated vacuum electronic systems, etc. Requirements and application scope of vacuum degree, breakthrough of technical bottleneck, effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

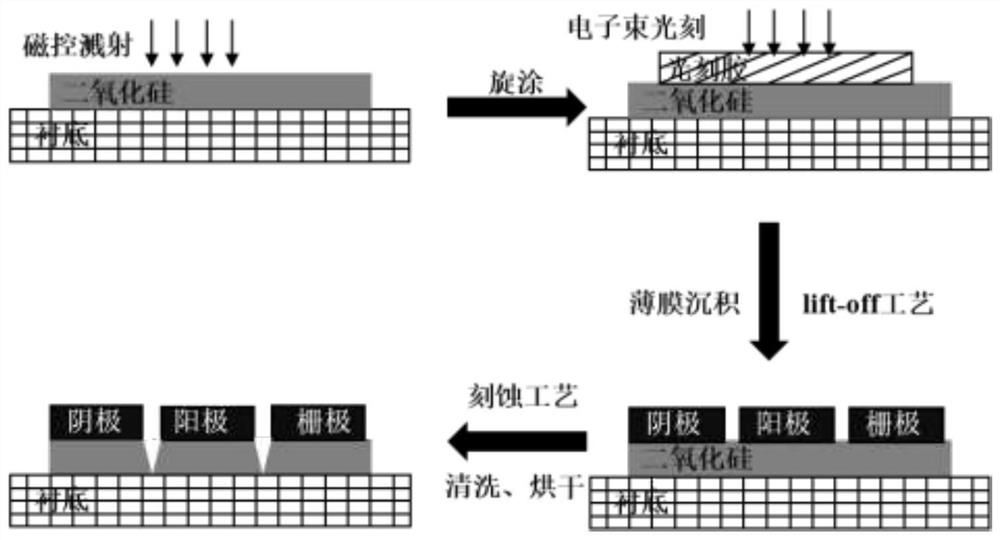

[0049] figure 2 A schematic flow chart of the preparation process of the vacuum channel nanogap triode in the present invention is shown. Take the cathode 2, anode 3 and gate 5 as an example of metal or semiconductor materials: first, the silicon wafer is ultrasonically cleaned with acetone, isopropanol and deionized water in sequence, and the surface is dried with nitrogen; magnetron sputtering is used on the polished surface Spin-coat photoresist, and use electron beam lithography to expose a preset pattern area on the sample surface; after developing with a mixed solution of isopropanol and methyl isobutyl ketone, use chemical vapor phase deposition or electron beam evaporation and other thin film deposition processes to prepare semiconductor or metal thin films as cathode 2, anode 3 and grid 5; Ultrasonic cleaning in ionized water; finally, use wet or dry or focused ion beam etching and other etching processes to remove the nano-gap 3 and the surrounding substrate materi...

Embodiment 2

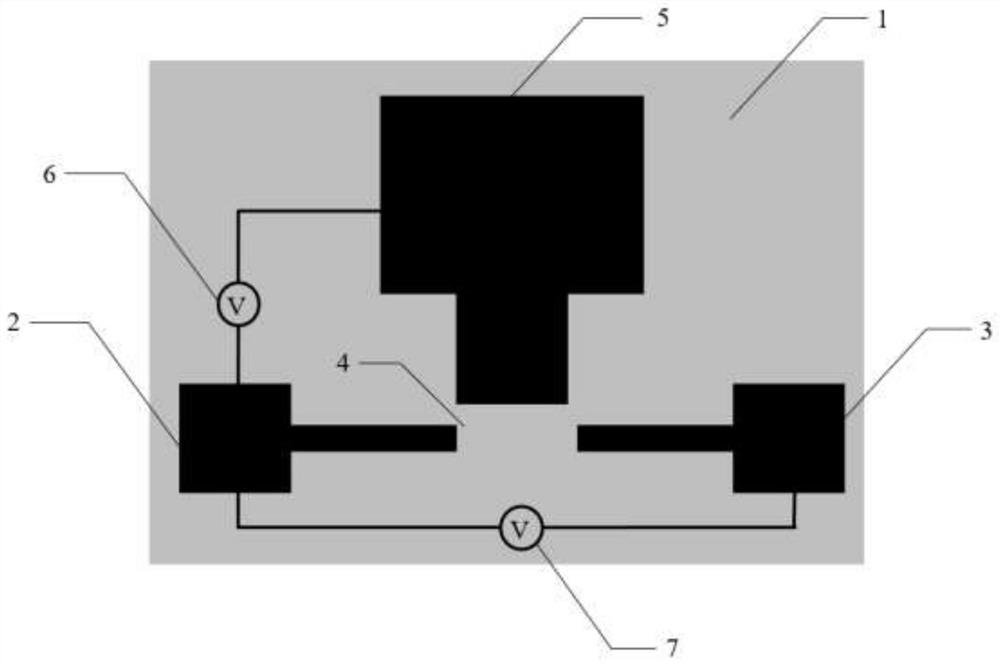

[0052] image 3 It is a plan view of the basic structure of the vacuum channel nano-gap triode in the present invention, and it is characterized in that: on the insulating base material 1, the cathode 2 and the grid 3 on the same straight line are made of conductive materials, and the cathode is connected to the anode and the grid. A gap 4 within 300 nanometers is kept between them, and an anode electrode 5 is arranged on one side of the gap region in the direction perpendicular to the straight line of the cathode and the grid. When the grid is applied with a modulation voltage 6 higher than that of the cathode, adjusting the grid modulation voltage can cause the cathode to emit electrons; setting a voltage 7 higher than the cathode on the anode and adjusting the anode voltage can make the electrons emitted by the cathode under the action of the anode voltage A part or all of them are hit on the anode, so as to form a nano-gap device triode structure with controllable current....

Embodiment 3

[0054] Figure 4 It is a top view of a V-type vacuum channel nano-gap triode in the present invention, and it is characterized in that: on the insulating base material 1, the cathode 2 and the grid 3 on the same straight line are made of conductive materials, and the cathode is connected to the anode, A V-shaped gap 4 within 300 nanometers is maintained between the gates, and an anode electrode 5 is arranged on one side of the gap region in a direction perpendicular to the straight line of the cathode and the grid. When the grid is applied with a modulation voltage 6 higher than that of the cathode, adjusting the grid modulation voltage can cause the cathode to emit electrons; setting a voltage 7 higher than the cathode on the anode and adjusting the anode voltage can make the electrons emitted by the cathode under the action of the anode voltage A part or all of them are hit on the anode, so as to form a nano-gap device triode structure with controllable current. The anode 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com