Preparation method of gelatinized material and method for comprehensive utilization of magnesium chloride tailing liquid by the same

A magnesium chloride tail liquid, coagulation technology, applied in the field of gelation and solidification, magnesium chloride tail liquid gelation and solidification, can solve the problems of high cost, poor industrial foundation, high price, etc., achieve low production cost, stable and reliable storage, reduce process link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

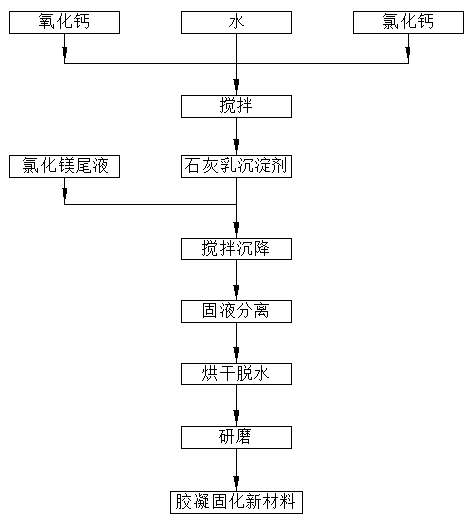

[0036] Such as figure 1 Shown, the preparation method of gelled solidified material of the present invention, carries out according to the following steps:

[0037] The first step, preparation of lime milk precipitant: prepare lime emulsion with water and lime according to the composition of water and calcium oxide mass ratio of 3:1, stir well with agitator, after the calcium oxide and water react completely, it is lime milk Precipitant;

[0038] The second step, mother liquor measurement: measure the magnesium chloride saturated mother liquor, and the measurement standard is: during the chemical reaction between the lime milk precipitant prepared in the first step and the magnesium chloride saturated mother liquor, the amount of magnesium chloride participating in the reaction accounts for 70% of the total magnesium chloride content in the mother liquor;

[0039] The third step, stirring and settling: add the lime milk precipitant prepared in the first step to the saturated...

Embodiment 2

[0045] Such as figure 1 Shown, the preparation method of gelled solidified material of the present invention, carries out according to the following steps:

[0046]The first step, preparation of lime milk precipitant: prepare lime emulsion with water and lime according to the composition of water and calcium oxide mass ratio of 4:1, stir well with agitator, after the calcium oxide and water react completely, it is lime milk Precipitant;

[0047] The second step, mother liquor measurement: measure the magnesium chloride saturated mother liquor, and the measurement standard is: during the chemical reaction between the lime milk precipitant prepared in the first step and the magnesium chloride saturated mother liquor, the amount of magnesium chloride participating in the reaction accounts for 80% of the total magnesium chloride content in the mother liquor;

[0048] The third step, stirring and settling: add the lime milk precipitant prepared in the first step to the saturated ...

Embodiment 3

[0054] Such as figure 1 Shown, the preparation method of gelled solidified material of the present invention, carries out according to the following steps:

[0055] The first step, preparation of lime milk precipitant: prepare lime emulsion with water and lime according to the composition of water and calcium oxide mass ratio of 3.5:1, stir well with a stirrer, after the calcium oxide and water react completely, it is lime milk Precipitant;

[0056] The second step, mother liquor measurement: measure the magnesium chloride saturated mother liquor, and the measurement standard is: during the chemical reaction between the lime milk precipitant prepared in the first step and the magnesium chloride saturated mother liquor, the amount of magnesium chloride participating in the reaction accounts for 75% of the whole magnesium chloride amount in the mother liquor;

[0057] The third step, stirring and settling: add the lime milk precipitant prepared in the first step to the saturat...

PUM

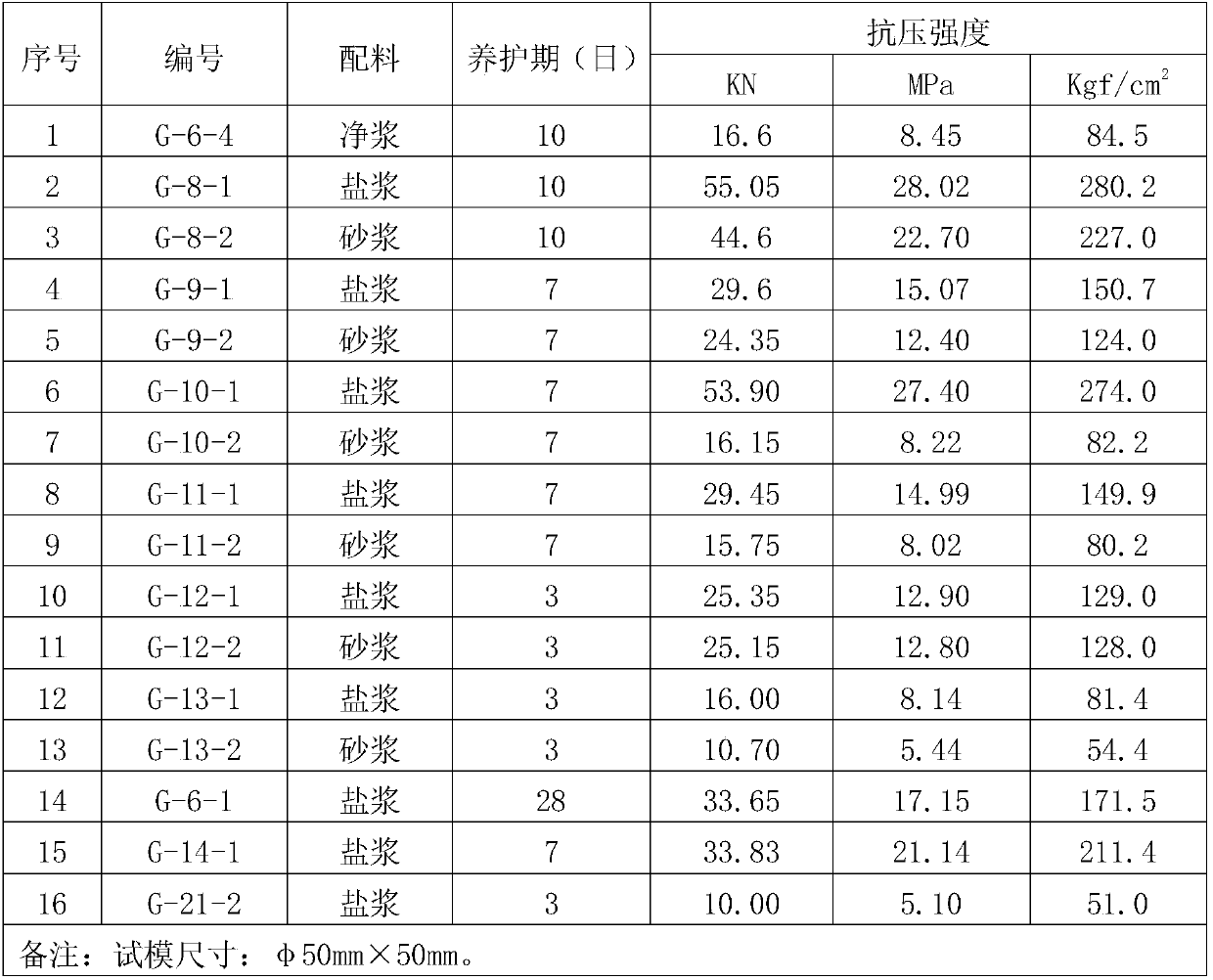

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com