Decorative colored cement-based surface self-leveling mortar

A technology of mortar and color paste, which is applied in the field of colored surface layer cement-based self-leveling mortar and its raw material composition, which can solve the problems of poor product leveling, easy shrinkage, cracking and poor decoration of the mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

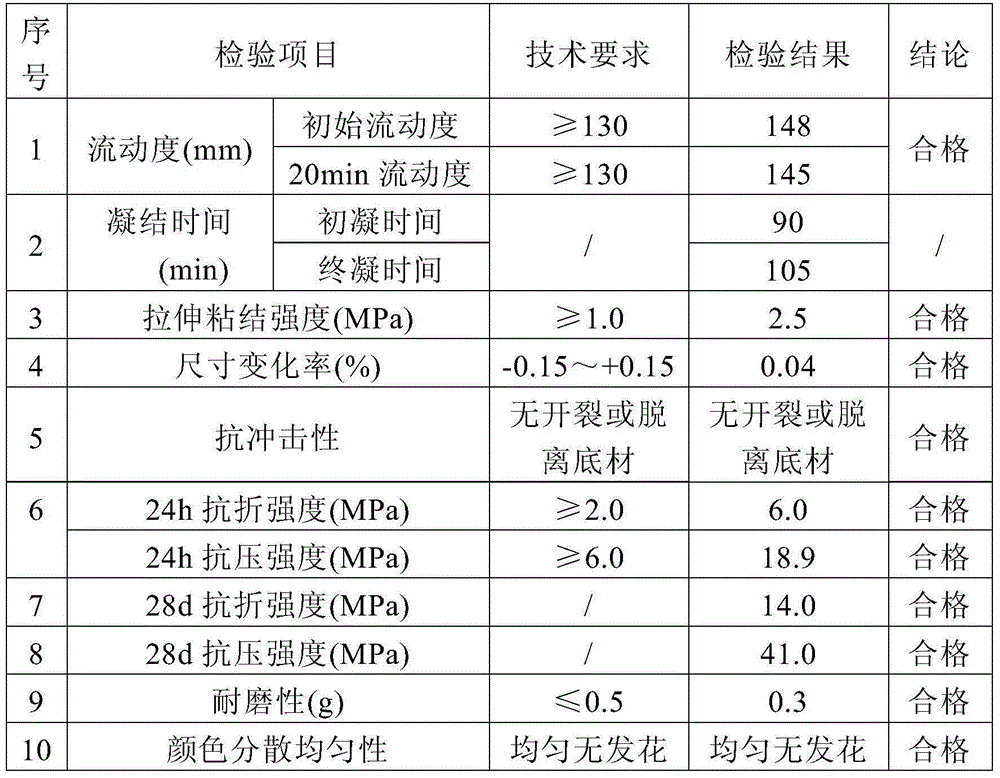

Embodiment 1

[0141] The lithium carbonate of 0.05 parts by weight, the water reducer of 0.15 parts by weight, the tartaric acid (citric acid) of 0.16 parts by weight, the cellulose ether (E230X) of 0.08 parts by weight, the defoamer (77-P) of 0.15 parts by weight, The wetting and dispersing agent (500s) of 0.1 weight part and the dispersible latex powder (FL2211) of 6.0 weight part are mixed uniformly and made into reagent bag and the ordinary portland cement (P.O42.5) of 16 weight parts, 18 weight parts Parts of aluminate cement (CA50), 6 parts by weight of anhydrite, 2 parts by weight of hemihydrate gypsum, 9 parts by weight of heavy calcium (or calcite, 500 mesh), 40.31 parts by weight of plain white sand (or quartz sand , wherein 24 parts by weight of 40-70 mesh sand, 16.31 parts by weight of 70-150 mesh sand), and 2 parts by weight of toner are mixed and stirred evenly to make mortar powder.

[0142] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio ...

Embodiment 2

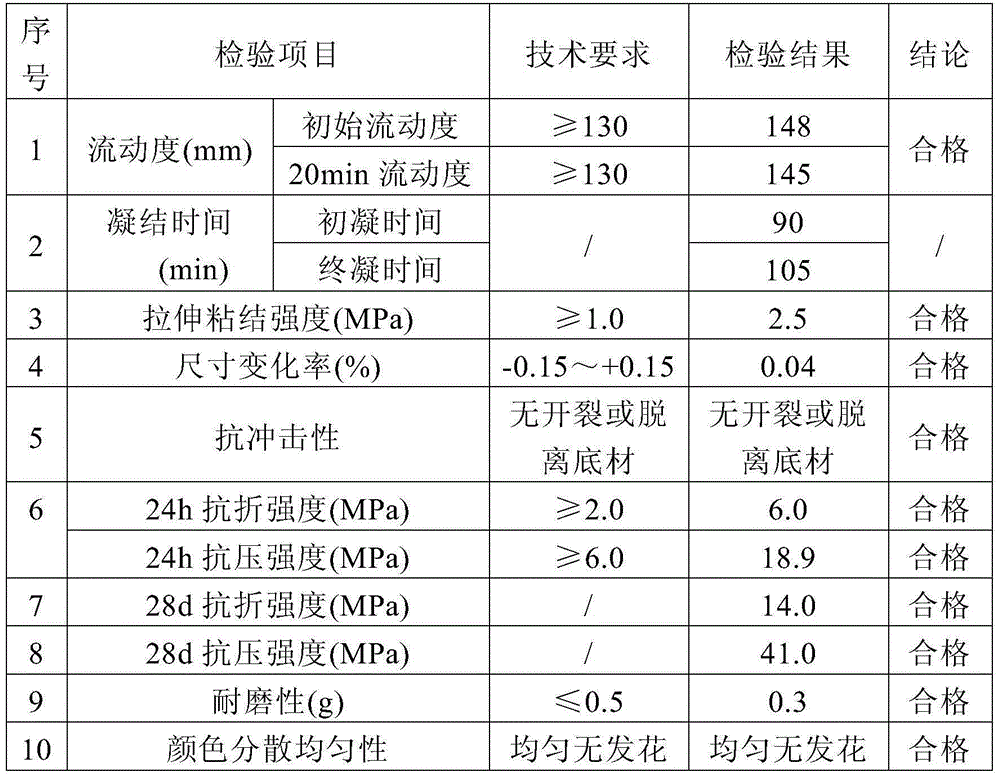

[0148] The lithium carbonate of 0.05 parts by weight, the water reducer of 0.15 parts by weight, the tartaric acid (citric acid) of 0.16 parts by weight, the cellulose ether (E230X) of 0.08 parts by weight, the defoamer (77-P) of 0.15 parts by weight, The wetting and dispersing agent (104s) of 0.1 weight part and the dispersible latex powder (FL2211) of 6.0 weight part are mixed uniformly and made into reagent bag and the ordinary portland cement (P.O42.5) of 16 weight parts, 18 weight parts Parts of aluminate cement (CA50), 6 parts by weight of anhydrite, 2 parts by weight of hemihydrate gypsum, 9 parts by weight of heavy calcium (or calcite, 500 mesh), 40.31 parts by weight of plain white sand (or quartz sand , wherein 24 parts by weight of 40-70 mesh sand, 16.31 parts by weight of 70-150 mesh sand), and 2 parts by weight of toner are mixed and stirred evenly to make mortar powder.

[0149] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio ...

Embodiment 3

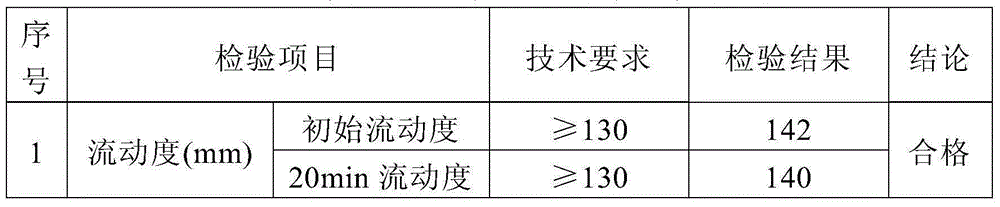

[0154] The lithium carbonate of 0.05 parts by weight, the water reducer of 0.15 parts by weight, the tartaric acid (citric acid) of 0.16 parts by weight, the cellulose ether (E230X) of 0.08 parts by weight, the defoamer (77-P) of 0.15 parts by weight, 0.1 parts by weight of wetting and dispersing agent (500s) and 4.0 parts by weight of dispersible latex powder (FL2211) are mixed evenly to make a reagent bag with 16 parts by weight of ordinary Portland cement (P.O42.5), 18 parts by weight Parts of aluminate cement (CA50), 6 parts by weight of anhydrite, 2 parts by weight of hemihydrate gypsum, 11 parts by weight of heavy calcium (or calcite, 500 mesh), 40.31 parts by weight of plain white sand (or quartz sand , wherein 24 parts by weight of 40-70 mesh sand, 16.31 parts by weight of 70-150 mesh sand), and 2 parts by weight of toner are mixed and stirred evenly to make mortar powder.

[0155] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com