Polymer and dispersion

A technology of polymer and dispersion liquid, applied in the field of its composition, can solve the problems of dispersing agent for dispersing conductive metal powder, different molecular size of dispersing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

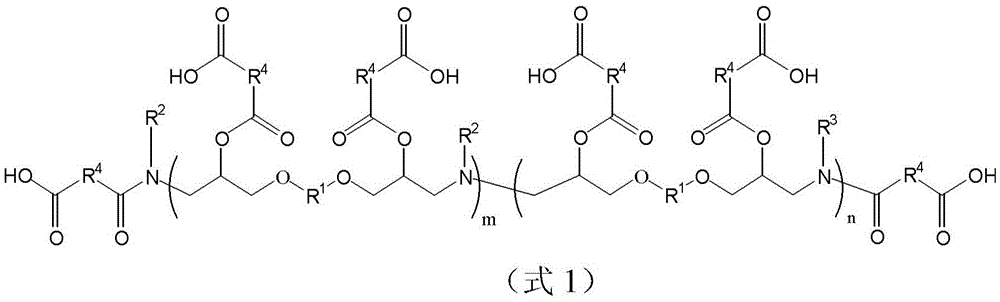

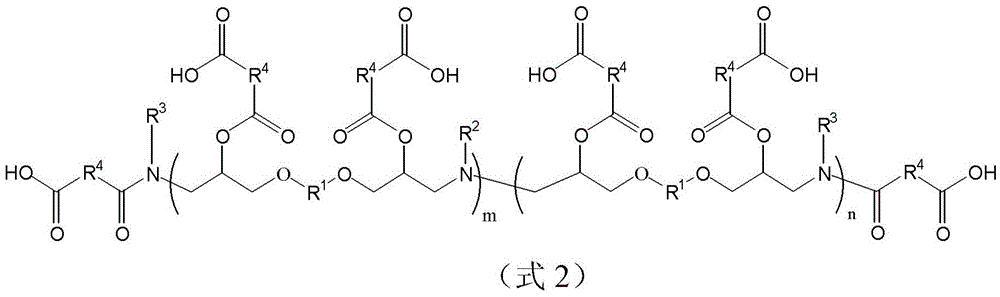

Method used

Image

Examples

Embodiment 1-1

[0029] Nitrogen was used to flush the reaction bottle, and 65.13 grams (32.56 mmol) of L-200 (purchased from HUNTSMAN), 10 grams (43.42 millimoles) of 1,6-hexanediol epoxy resin (purchased from Changchun Chemical Industry), 4.21 grams (32.56 millimoles) of octylamine (purchased from Aldrich) In the reaction flask, mechanically stirred and heated to 120° C., and then reacted for 4 hours. The above reaction is shown in formula 6.

[0030]

[0031] Cool down to 70°C afterwards, add 13.04 grams (130.26 mmol) of cyclosuccinic anhydride, react at 70°C for 12 hours, then heat up to 110°C for 3 hours to obtain a comb-like (comb-like) polymer ( Yield 99%, yellow liquid). The molar ratio of above-mentioned reactant is as follows: 1,6-hexanediol epoxy resin: octylamine: L-200: cyclosuccinic anhydride = 4:3:3:12. The above reaction is shown in formula 7.

[0032]

[0033]

[0034] The relevant spectral data are as follows: 1 H NMR (DMSO-d 6 , δ, ppm): 0.84(t), 1.02(d), 1...

Embodiment 1-2

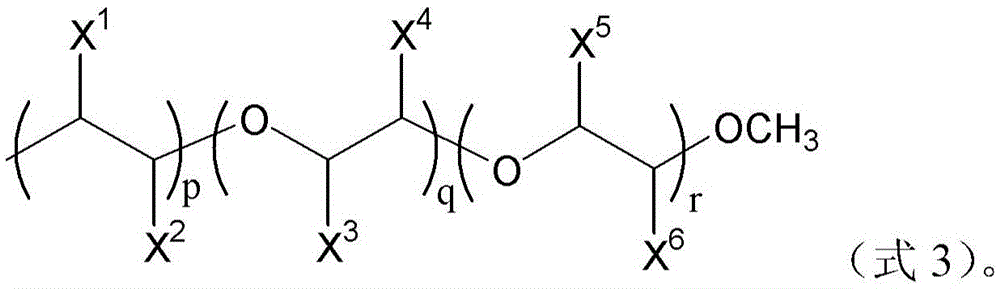

[0036] Similar to Example 1-1, the difference is that R 3 -NH 2 Depend on L-200 is replaced by L-100, its structure is shown in Formula 8.

[0037]

[0038] The relevant spectral data are as follows: 1 H NMR (DMSO-d 6 , δ, ppm): 0.84(t), 1.02(m), 1.18(d), 1.22(b), 1.46(s), 2.40(s), 2.45(s), 3.23(s), 3.40~3.50( m), 4.97(d), 12.05(s). 13 CNMR (DMSO-d 6 , δ, ppm): 14.1, 17.2, 22.3, 25.6, 28.8, 28.9, 29.3, 31.4, 58.2, 69.8~70.7(m), 71.5, 74.4, 173.7(C=O).IR(KBr): 3469cm -1 (acid O-H stretch), 2921, 2870cm -1 (alkyl C-H stretch), 1730cm -1 (ester stretch), 1640cm -1 (C=O stretch)), 1104cm -1 (C-O-C stretch).

Embodiment 1-3

[0040] Similar to Example 1-1, the difference is that R 3 -NH 2 Depend on L-200 is replaced by L-300, its structure is as formula 9.

[0041]

[0042] The relevant spectral data are as follows: 1 H NMR (DMSO-d 6 , δ, ppm): 0.84(t), 1.02(d), 1.11(d), 1.23(b), 1.47(s), 2.40(s), 3.23(s), 3.32(s), 3.36~3.54( m), 5.07(d), 11.86(s). 13 C NMR (DMSO-d 6 , δ, ppm): 14.1, 17.3, 22.3, 28.2, 28.8, 28.9, 29.3, 31.4, 58.2, 67.9, 69.8~70.3(m), 71.5, 74.3, 74.4, 173.8(C=O).IR(KBr) : 3510cm -1 (acid O-H stretch), 2910, 2870cm -1 (alkyl C-H stretch), 1730cm -1 (ester stretch), 1640cm -1 (C=O stretch), 1110cm -1(C-O-C stretch).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com