Multifunctional coating for polyethylene candy packaging film

A packaging film and multi-functional technology, applied in the field of coatings, can solve the problems of incomplete holographic effect, limited development, low production efficiency, etc., and achieve the effect of outstanding coating anti-counterfeiting effect, good coating adhesion fastness, and convenient coating preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

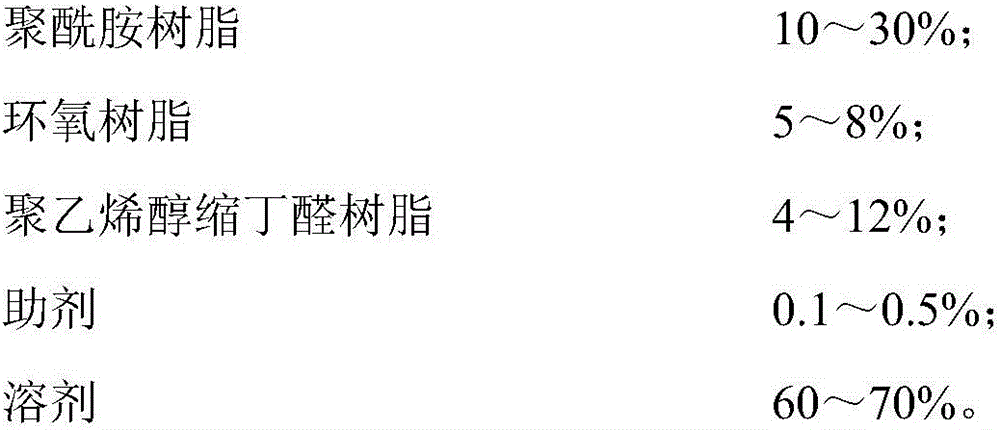

Method used

Image

Examples

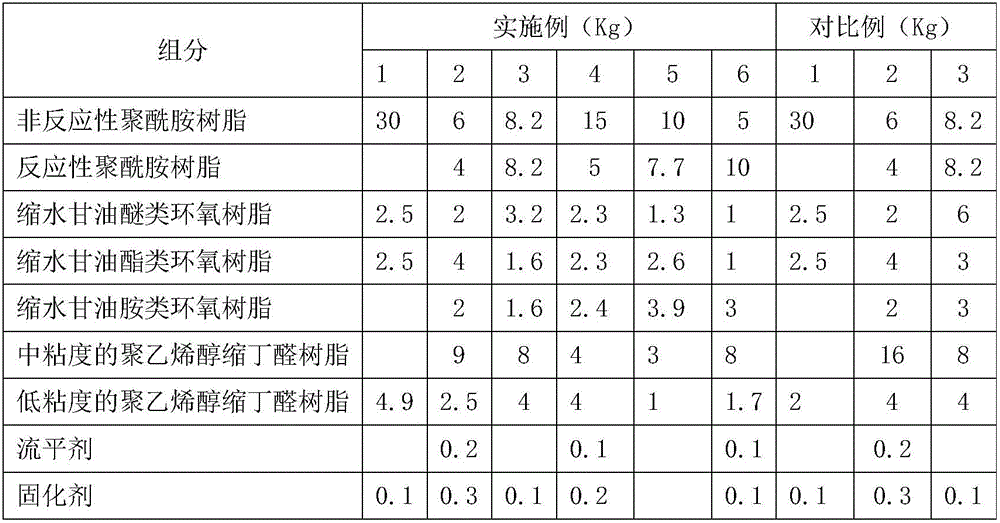

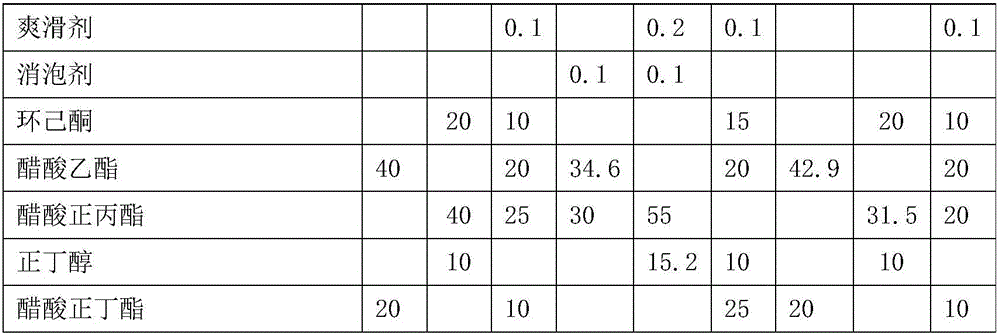

Embodiment 1

[0030] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0031] (1) 40 kilograms of ethyl acetate and 20 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 60° C.;

[0032] (2) 30 kilograms of non-reactive polyamide resins, 2.5 kilograms of glycidyl ether epoxy resins, 2.5 kilograms of glycidyl ester epoxy resins, and 4.9 kilograms of low-viscosity polyvinyl butyral resins are dropped into the reactor, Stir at high speed for 4.0 hours until fully dissolved;

[0033] (3) Add 0.1 kg of curing agent into the reaction kettle and stir until it is evenly dispersed.

[0034] The paint is directly coated on the coating machine, the leveling is good, the coating surface is flat, the molding temperature is 80-95 ℃, the molding effect is goo...

Embodiment 2

[0036] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0037] (1) 20 kilograms of cyclohexanone, 40 kilograms of n-propyl acetate, and 10 kilograms of n-butanol are dropped into the reactor, and the temperature is raised to 55° C.;

[0038] (2) 6.0 kg of non-reactive polyamide resin, 4.0 kg of reactive polyamide resin, 2.0 kg of glycidyl ether epoxy resin, 4.0 kg of glycidyl ester epoxy resin, 2.0 kg of glycidyl amine epoxy resin , 9.0 kilograms of medium-viscosity polyvinyl butyral resin, 2.5 kilograms of low-viscosity polyvinyl butyral resin are put into the reaction kettle, stirred at high speed for 2.5 hours, until fully dissolved;

[0039] (3) Add 0.2 kg of leveling agent and 0.3 kg of curing agent into the reaction kettle in turn, and stir well until the dispersio...

Embodiment 3

[0042] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0043] (1) 10 kilograms of cyclohexanone, 20 kilograms of ethyl acetate, 25 kilograms of n-propyl acetate, and 10 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 60° C.;

[0044] (2) 8.2 kg of non-reactive polyamide resin, 8.2 kg of reactive polyamide resin, 3.2 kg of glycidyl ether epoxy resin, 1.6 kg of glycidyl ester epoxy resin, 1.6 kg of glycidyl amine epoxy resin , 8.0 kilograms of medium-viscosity polyvinyl butyral resin, 4.0 kilograms of low-viscosity polyvinyl butyral resin are put into the reaction kettle, stirred at high speed for 3.0 hours, until fully dissolved;

[0045] (3) Add 0.1 kg of smoothing agent and 0.1 kg of curing agent into the reaction kettle in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com