Clean production method of bamboo fiber

A production method, bamboo fiber technology, applied in the direction of fiber chemical post-treatment, fiber treatment, fiber mechanical separation, etc., can solve the problems of increasing production links, environmental pollution, increasing energy consumption and environmental pollution, etc., to achieve improved production efficiency, reduce labor costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] First Example: Processing Coarse Bamboo Fibers for Composite Materials

[0042] Step 1: Divide the fresh bamboo into bamboo strips, remove bamboo green, bamboo yellow, and bamboo knots, and make bamboo slices, use the splitting equipment to make bamboo slices into bamboo threads that are not involved with each other, and then twist them by the rope forming device into continuous rope-like bamboo filaments. The equivalent diameter of the main body of the bamboo wire is 0.5 mm.

[0043] Step 2: The rope-like bamboo filament is fed into the multiple microwave refinement equipment with 10 pairs of grooved rollers by the automatic conveying and buffering device. Between every two pairs of grooved rollers, a microwave heating device and a cold water shower device are arranged alternately to Repeated rolling, heating, rolling, and cooling, that is, alternating cold and heat plus rolling. The conveying speed is mastered in 30 minutes according to the processing time of any se...

no. 2 example

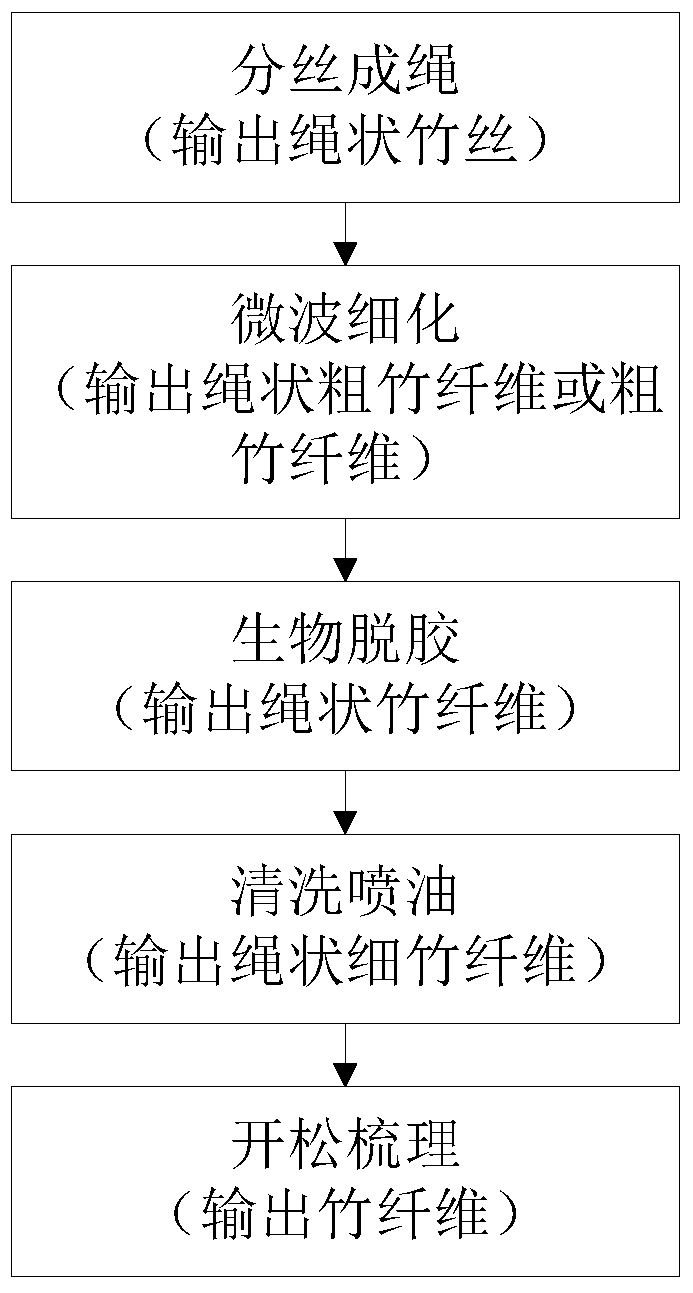

[0045] The second embodiment: as figure 1 shown, processing bamboo fibers for textile nonwovens

[0046] Step 1: Divide the fresh bamboo into bamboo strips, remove bamboo green, bamboo yellow, and bamboo knots, and make bamboo slices, use the splitting equipment to make bamboo slices into bamboo threads that are not involved with each other, and then twist them by the rope forming device into continuous rope-like bamboo filaments. The equivalent diameter of the main body of the bamboo wire is 0.5 mm.

[0047] Step 2: The rope-like bamboo filament is fed into the multiple microwave refinement equipment with 15 pairs of grooved rollers by the automatic conveying and buffering device. Between every two pairs of grooved rollers, a microwave heating device and a cold water shower device are arranged alternately, that is, Rolling, heating, rolling, and cooling are repeated, that is, alternating cold and heat plus rolling. The conveying speed is controlled in 45 minutes according ...

no. 3 example

[0054] Third Example: Processing Bamboo Fibers for Spinning Woven Materials

[0055] Step 1: Divide the fresh bamboo into bamboo strips, remove bamboo green, bamboo yellow, and bamboo knots, and make bamboo slices, use the splitting equipment to make bamboo slices into bamboo threads that are not involved with each other, and then twist them by the rope forming device into continuous rope-like bamboo filaments. The equivalent diameter of the main body of bamboo wire is 0.5mm.

[0056] Step 2: The rope-like bamboo filament is fed into the multiple microwave thinning equipment with 20 pairs of grooved rollers by the automatic conveying and buffering device. Between every two pairs of grooved rollers, a microwave heating device and a cold water shower device are arranged alternately, that is Rolling, heating, rolling, and cooling are repeated, that is, alternating cold and heat plus rolling. The conveying speed is controlled by 60 minutes according to the processing time of any...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com