Shear wall structure with rectangular steel pipe rows with vertical gaps

A technology for rectangular steel pipes and shear walls, which is applied in the direction of walls, building components, and building structures, and can solve the problem of reduced lateral bearing capacity and stiffness of steel plate shear walls, high requirements for vertical joint dimensional accuracy, and low bending and torsional stiffness and other problems, to achieve the effect of improving edge restraint, improving lateral bearing capacity, and increasing plastic bending moment value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

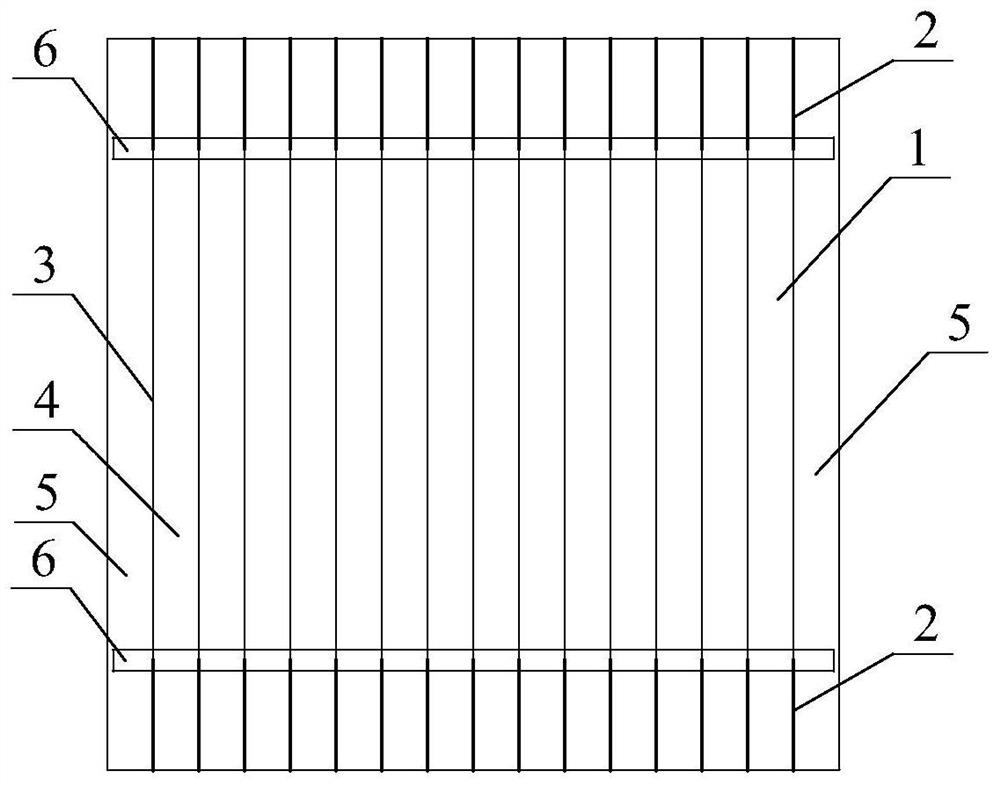

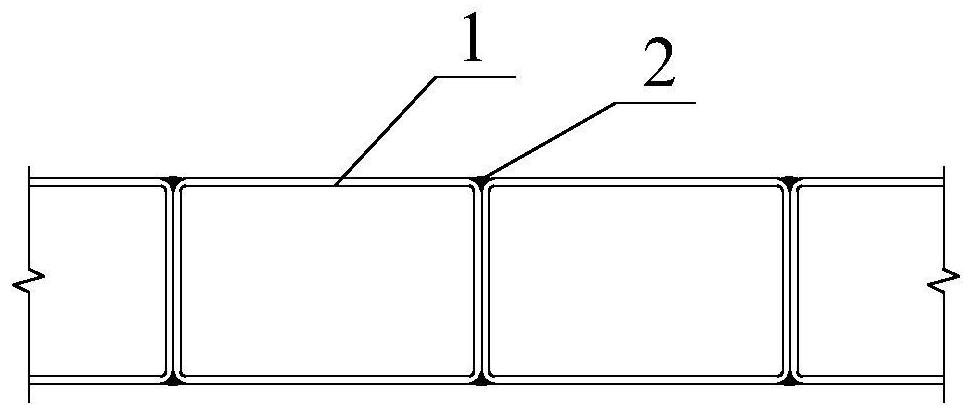

[0043] like figure 1 As shown, the ends of the adjacent rectangular steel pipes 1 are connected by connecting welds 2 between the ends of the upper and lower ends, and the two adjacent steel pipes are connected by the connecting welds at the junction of the steel pipe flange and the web, as shown in the figure. figure 2 As shown, a row of bending small columns 4 located in the middle of the rectangular steel pipe 1 is formed, thereby forming two upper and lower rows of connection welds 2 and a row of vertical gaps 3 between the upper and lower rows of connection welds 2, adjacent vertical The gap is separated by a rectangular steel pipe, and each bending column 4 is composed of a single rectangular steel pipe 1 .

[0044] And weld a transverse reinforcing steel strip 6 at both ends of the middle row of bending small columns 4 to strengthen, that is, the junction of the upper row of connection welds 2 and the vertical gap 3 and the lower row of connection welds 2 and the verti...

Embodiment 2

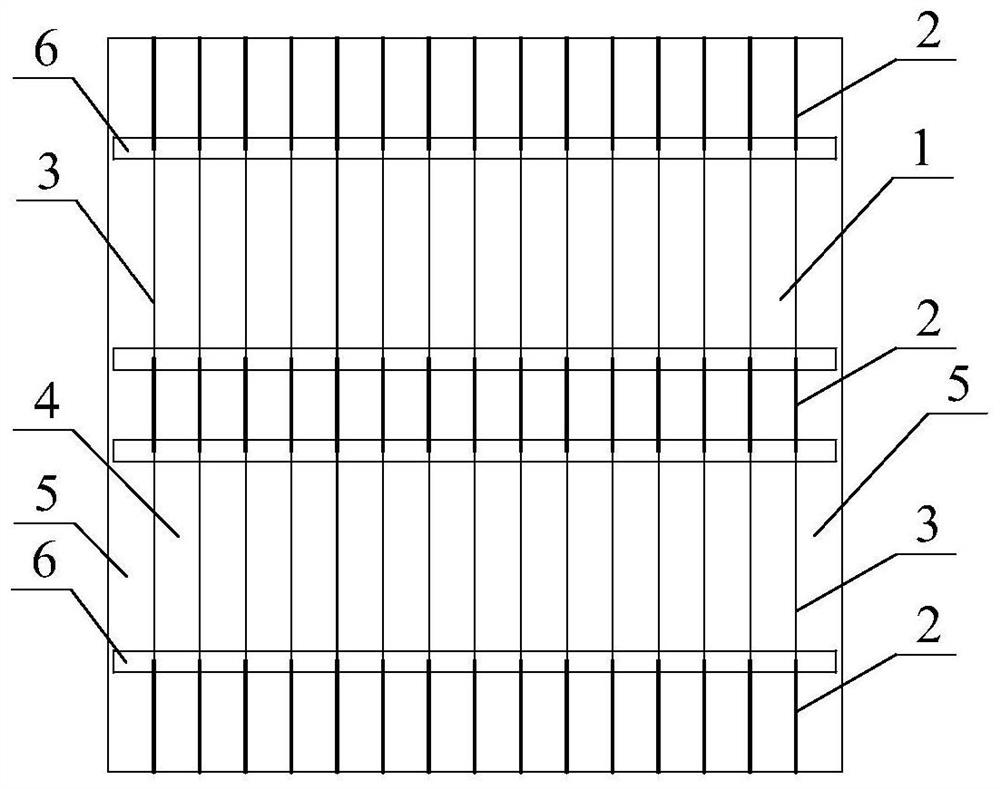

[0047] like image 3 As shown, the adjacent rectangular steel pipes 1 are connected by connecting welds 2 between the upper ends, the middle parts and the lower ends, forming two rows of bending columns 4 located in the middle of the rectangular steel pipes 1, forming three upper, middle and lower parts. Row of connection welds 2 and vertical gaps 3 between the upper and middle row of connection welds 2 and between the middle and lower row of connection welds 2; A transverse reinforcing steel strip 6 is welded for reinforcement, that is, at the junction of the upper row of connection welds 2 and the upper row of vertical gaps 3, the junction of the middle row of connection welds 2 and the upper row of vertical gaps 3, and the middle row of connection welds. Horizontal reinforcement steel strips 6 arranged horizontally and horizontally are welded at the junction of seam 2 and the lower row of vertical gaps 3 and at the junction of the lower row of connection welds 2 and the low...

Embodiment 3

[0050] like Figure 4 As shown, take two adjacent rectangular steel pipes 1 as a group, each group of rectangular steel pipes 1 is connected by the entire vertical connecting weld 2, and adjacent two groups of rectangular steel pipes 1 are between the ends of the upper and lower ends. They are all connected by connecting welds 2 to form a row of bending small columns 4 located in the middle of the rectangular steel pipe 1, and each bending small column 4 is composed of two rectangular steel pipes 1, thereby forming two upper and lower rows of connecting welds 2 and the upper and lower columns. Alternately arranged connection welds 2 and vertical gaps 3 between the two rows of connection welds 2; and weld a transverse reinforcement steel strip 6 at both ends of each group of bending columns 4 in the middle to strengthen, and the transverse reinforcement steel strips The four sides of 6 are welded with the rectangular steel pipe 1 by fillet welds.

[0051] The specific elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com