Vertical shaft restoration and reinforcement structure and restoration and reinforcement construction method

A technology for strengthening structures and construction methods, applied in basic structure engineering, shaft equipment, excavation, etc., can solve problems such as shaft scrapping, expansion of collapse range, exposed original rock, etc., and achieve the effect of short construction period, easy construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

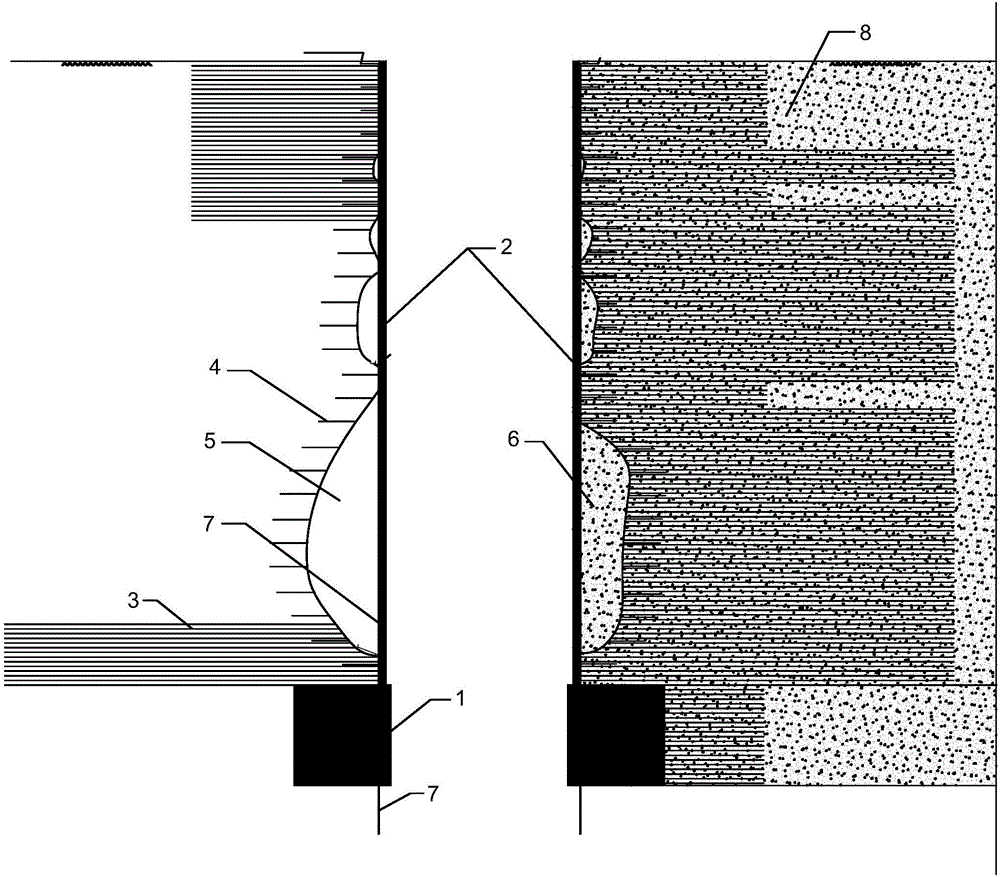

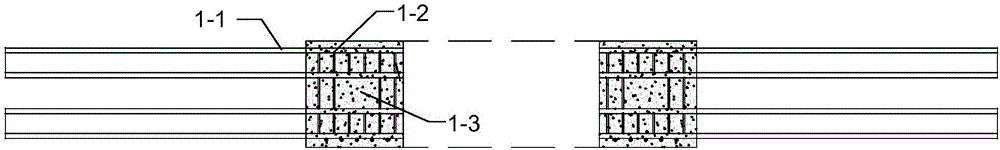

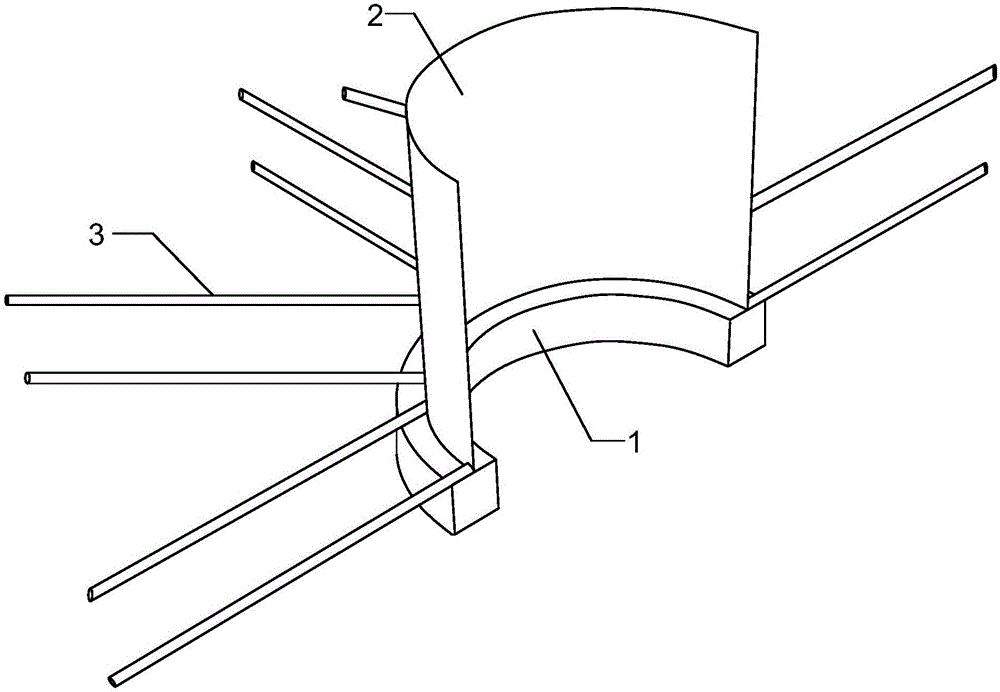

[0025] Embodiment: This embodiment is specifically aimed at the repair and reinforcement construction of a mineral shaft in a cement plant in Yunnan. The shaft adopts short bolt grouting measures in the early stage, and the water seepage rate is reduced by 20-35%, and the shaft wall still collapses, which is not enough to meet the production demand. In order to solve the problems of shaft wall collapse and water seepage, the technical scheme of the present invention is adopted to reinforce and repair the shaft wall. The specific implementation steps are as follows:

[0026] (1) First, according to the seepage situation of the shaft and the design drawings, bolt drilling and grouting are used at the seepage part of the shaft wall to reinforce the surrounding rock in the broken and seepage area inside the shaft, and to stop the seepage part of the shaft wall; among them, the wellbore The shaft wall of 0~-110m is better. There are 4 bolts in one ring, each hole is 3m deep, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com