Armored thermocouple sensor

A thermocouple sensor, armored technology, used in instruments, thermometers, measuring devices with directly sensitive electrical/magnetic components, etc. To ensure insulation, improve strength and vibration resistance, and achieve the effect of excellent vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with description wind accompanying drawing.

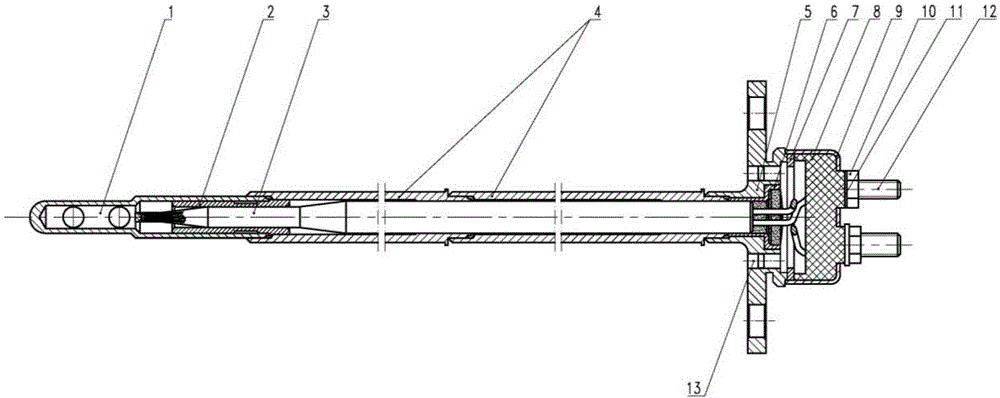

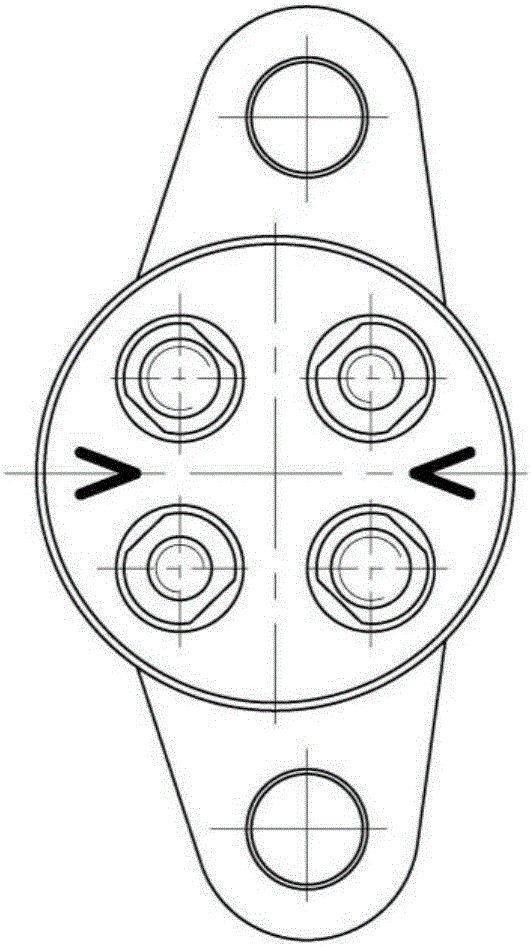

[0014] An armored thermocouple sensor, including a nozzle 1, a first bushing 2, an armored thermal electrode 3, an outer casing 4, a flange 5, a second bushing 6, a saddle-shaped elastic washer 7, and an insulating seat 8 , mounting plate 9, nut 10, washer 11, terminal 12; armored thermode 3 is a cylindrical rod-shaped structure, and the outer surface of one end is installed with the first bushing 2, and protrudes from the first bushing 2, and the two pass through Hexagonal compression, the first bushing 2 is installed with a nozzle 1 by argon arc welding, and the outer casing 4 is welded on the outside of the armored thermode 3; the other end of the armored thermode 3 is installed on the French On one side of the blue plate 5, the mounting plate 9 is installed on the other side of the flange plate 5. An insulating seat 8 is installed inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com