Composite transparent fluorescent ceramic chip and preparing method for white LEDs

A fluorescent ceramic, LED chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the luminous effect and service life of the device, high color temperature, not soft, etc., to improve the luminous efficiency and service life, good luminescence effect, effect of high color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

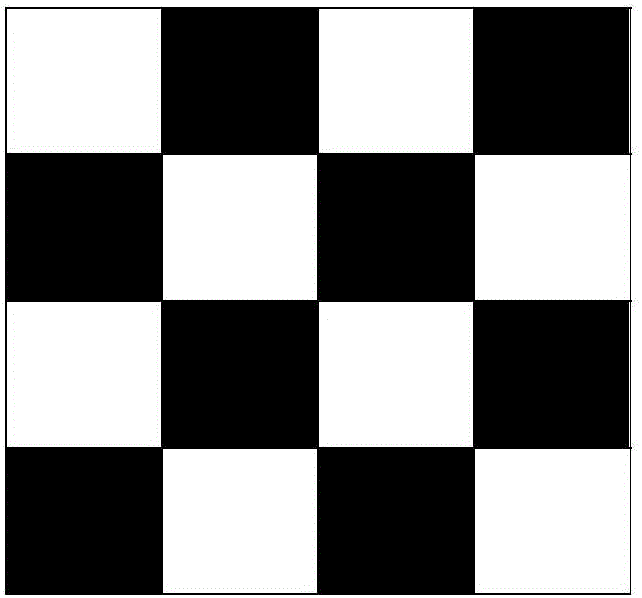

[0036] In this embodiment, the thickness of the composite transparent fluorescent ceramic sheet is 0.5 mm, and its surface is as figure 1 As shown, 4*4 small ceramic units are closely connected in cross-section to form an overall structure. Each small ceramic unit has the same structure and a square structure, forming a 4*4 square array structure as a whole.

[0037] In this embodiment, the excitation light source adopts a blue LED chip. When the excitation light source independently excites each small ceramic unit, it emits two colors of light, red light and yellow light, that is, each small ceramic unit is a light-emitting pixel point, each light-emitting Pixels can be divided into red light pixels and yellow light pixels according to the color of light emitted after excitation, such as figure 1 The white squares in the figure represent yellow light pixels, and the black squares represent red light pixels. When the composite transparent fluorescent ceramic sheet is excited ...

Embodiment 2

[0048] In this embodiment, the structure of the composite transparent fluorescent ceramic sheet is basically the same as that of the composite transparent fluorescent ceramic sheet in Example 1, except that the red light pixels are all composed of YAG:Pr 3+ Composed of materials, the yellow light pixels are all made of YAG:Ce 3+ Material composition.

[0049] The preparation method of the composite transparent fluorescent ceramic sheet is as follows:

[0050] In YAG:Pr 3+ It is a ceramic powder that glows red after excitation, using deionized water as a solvent, sodium polyacrylate (PAAS) as a dispersant, methyl cellulose (MC) as a binder, and glycerol as a plasticizer , adding 0.6% of PAAS to obtain a stable dispersion of YAG:Pr 3+ Powder suspension, after ball milling for 8 hours, add 1.5% MC and 1.2% glycerol, and continue ball milling for 20 hours to obtain red light ceramic slurry;

[0051] With YAG:Ce 3+ It is the ceramic powder of the pixels that emit yellow light ...

Embodiment 3

[0056] In this embodiment, the structure of the composite transparent fluorescent ceramic sheet is basically the same as that of the composite transparent fluorescent ceramic sheet in Example 1, the difference is that the red light pixels are all composed of YAG:Eu 3+ Composed of materials, the yellow light pixels are all made of YAG:Ce 3+ Material composition.

[0057] The preparation method of the composite transparent fluorescent ceramic sheet is basically the same as the preparation method in Example 1, except that the red light pixels are all composed of YAG:Eu 3+ Composed of materials, the yellow light pixels are all made of YAG:Ce 3+ Material composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com