Position failure fault-tolerant driving control method for wind power generation pitch system

A pitch system, fault technology, applied in the direction of motor control, motor generator control, AC motor control, etc., can solve the problems of fan damage, limited size, sensor occupying motor system space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

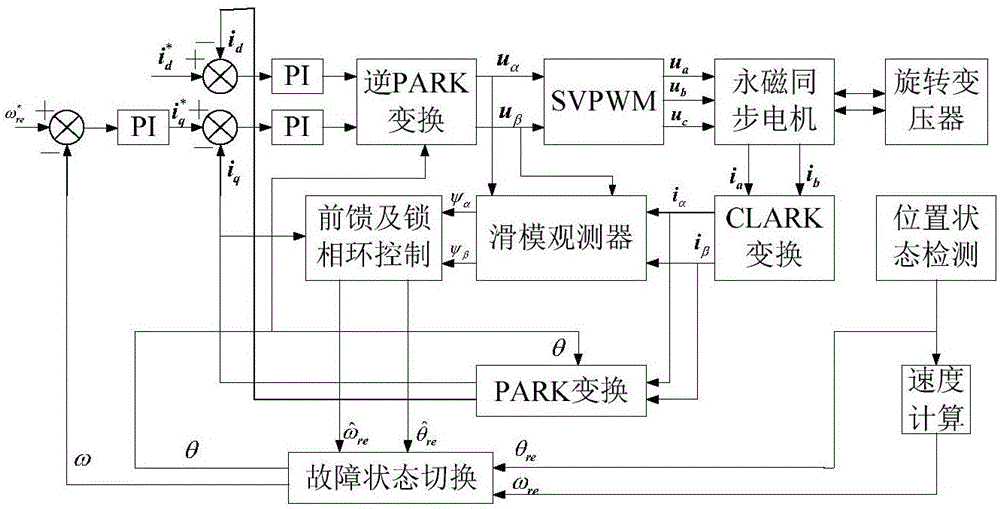

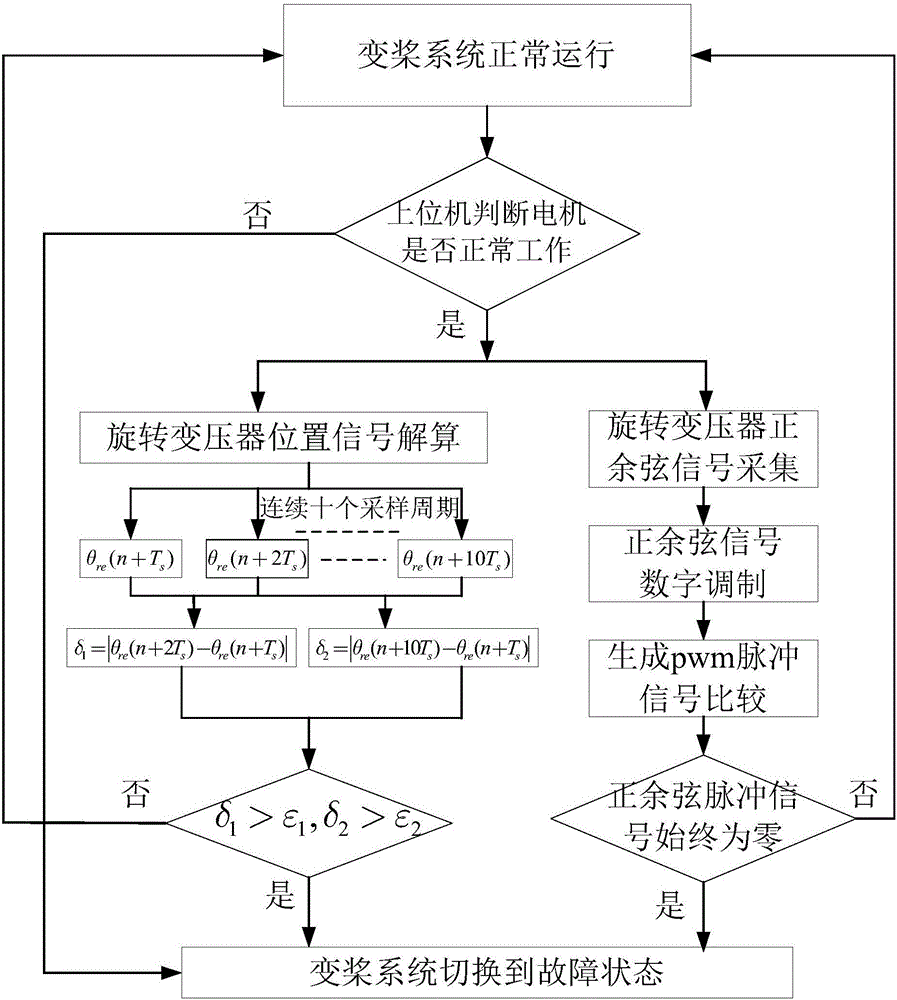

[0021] Such as Figure 1 to Figure 6 As shown, a position fault-tolerant drive control method for a wind power generation pitch system involved in this embodiment:

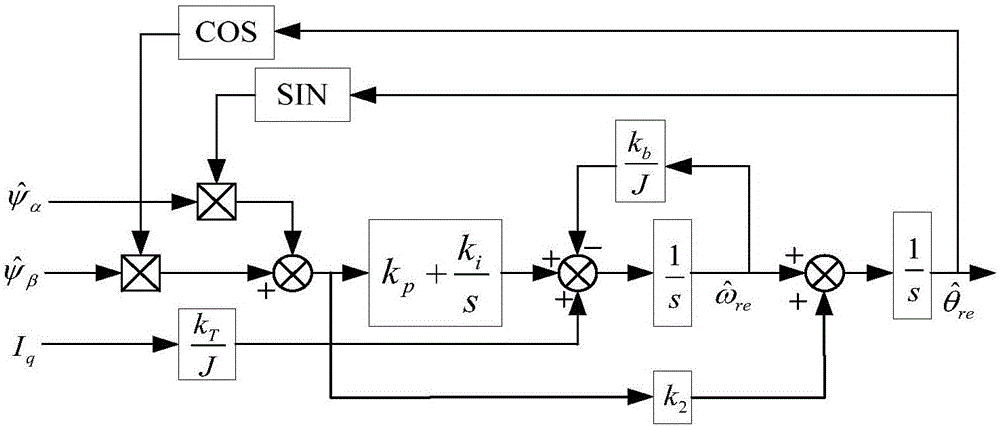

[0022] 1. Position and speed Position estimation:

[0023] The block diagram of the drive control principle of the permanent magnet synchronous motor of the variable pitch system for wind power generation is as follows: figure 1 shown. according to figure 1 , the two-phase current i of the permanent magnet synchronous motor a ,i b , Bus voltage U dc , The SIN and COS signals of the resolver are detected by A / D and collected into the microprocessor, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com