Shear type wolfberry picking machine

A picking machine and shearing technology, applied in the field of shearing wolfberry picking machines, can solve the problems of difficulty in picking and sorting, unable to pick wolfberry, economic loss, etc., so as to improve the picking rate and transportation efficiency, and reduce wolfberry. Damage rate and effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

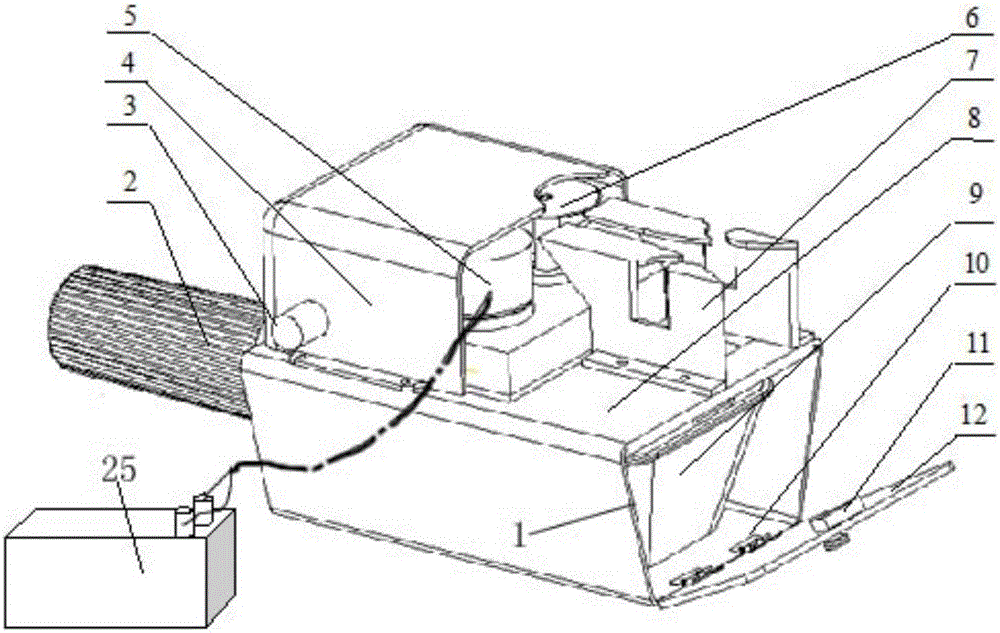

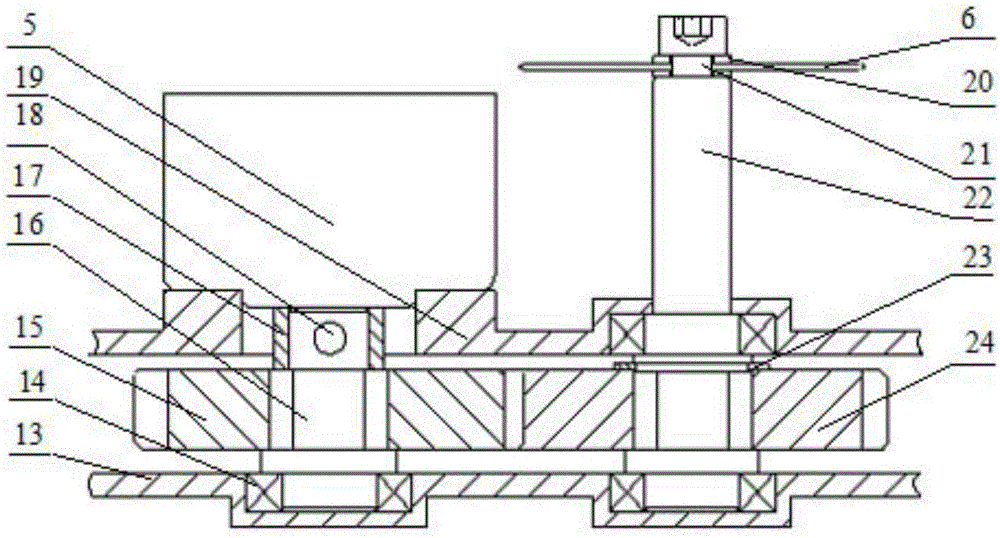

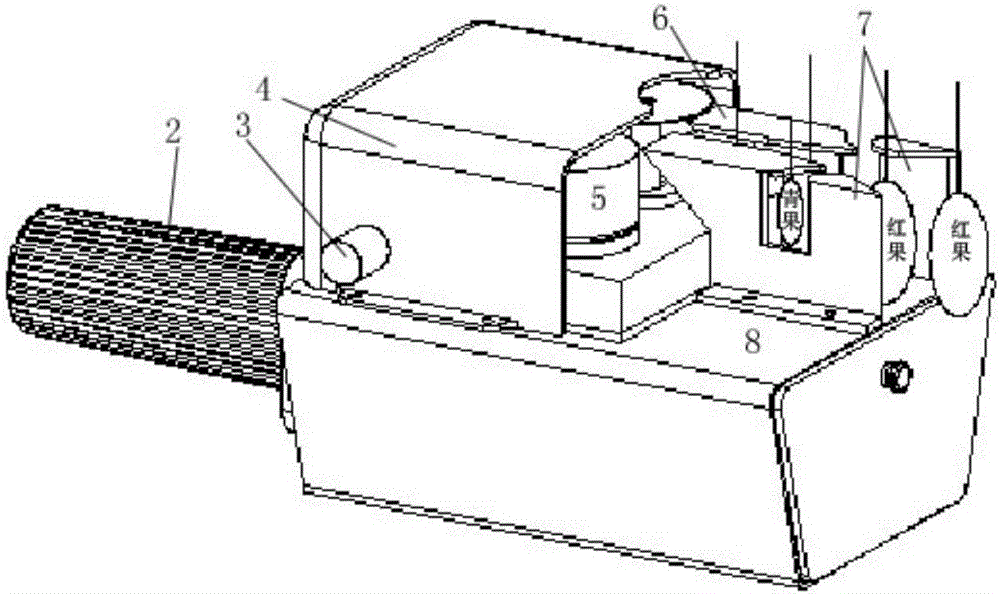

[0014] The invention provides a shearing type wolfberry picking machine; it will be described below in conjunction with the accompanying drawings.

[0015] figure 1 The structure diagram of wolfberry shear picking machine is shown. The wolfberry picking machine in the figure is composed of a fruit handle cutting unit, a gear transmission unit, an electrical control unit and a wolfberry collecting unit; wherein, the blade 6 is fixed on the top of the driven shaft 22 by screws 21 and spacers 20, and the middle plate 19 is fixed on the frame 1 top surface, the DC motor 5 and the driven shaft 22 are fixed side by side on the middle plate 19, the protective cover 4 covers the DC motor 5 and the driven shaft 22, and the governor 3 is fixed on one side of the protective cover 4 Grain divider 7 is fixed on both sides of the driven shaft 22 below the blade 6; the front, left and right sides of the frame 1 form a storage box 8, and the storage box import is provided with the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com