Combined dust removal equipment

A dust removal equipment and combined technology, which is applied in the field of combined dust removal equipment, can solve the problems of difficulty in making dust removal equipment, single structure of dust removal equipment, and limited use range, and achieve the effects of low production cost, reduced transportation cost, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific examples.

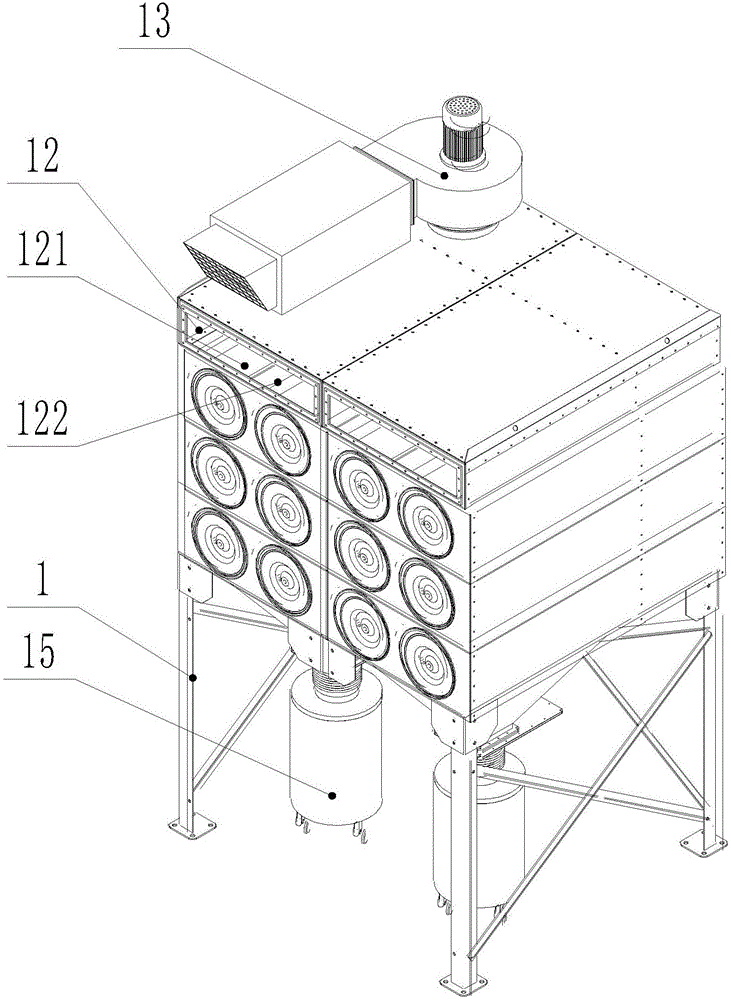

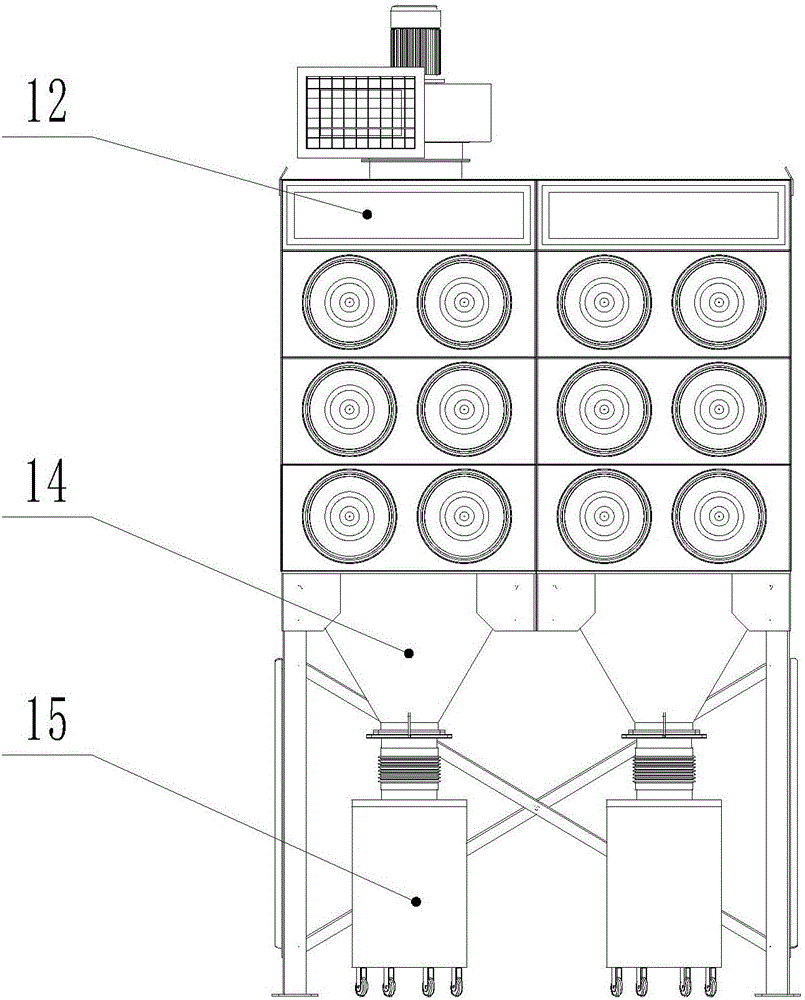

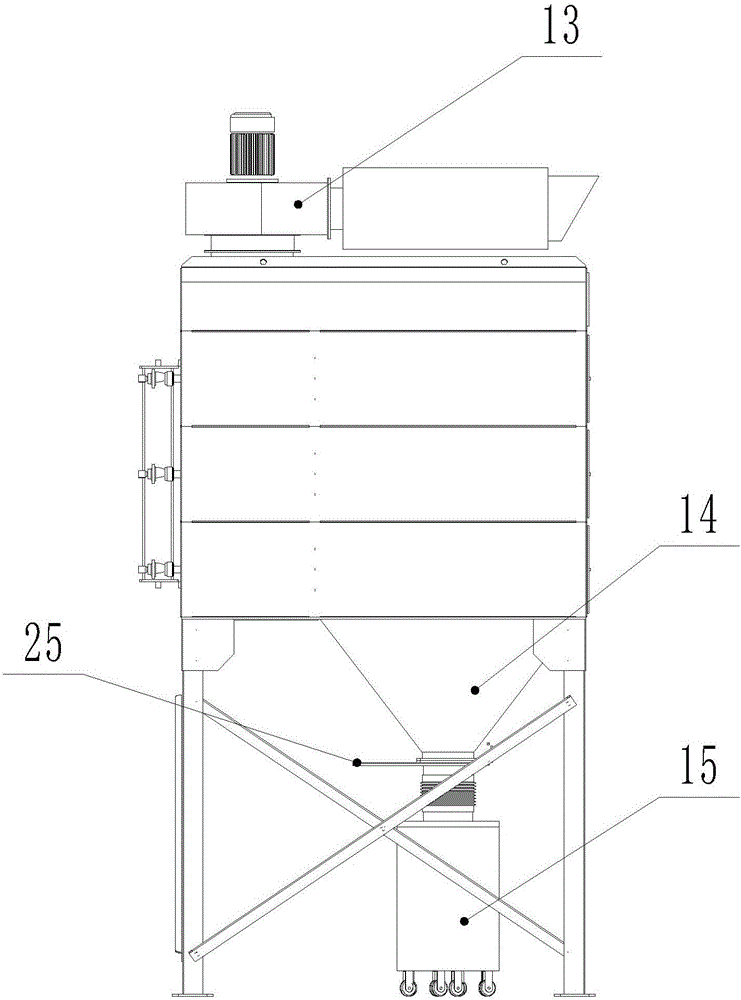

[0029] Such as Figures 1 to 6 As shown, the definitions of up, down, front, back, left and right are as follows figure 2 The state shown in is the baseline, and the observer faces figure 2 Determined, the vertical paper faces inwards.

[0030] A combined dust removal device, comprising at least one dust remover unit, the dust remover unit includes several dust removal module monomers 2, the dust removal module monomers 2 are stacked and installed up and down, and each dust removal module monomer 2 is a cuboid structure , wherein, the dust removal module monomer 2 contained in each dust collector unit has the same size, and the dust removal module monomer 2 of different dust collector units can have the same height and front and rear length, and the left and right widths can be different.

[0031] Such as Figure 5 with Image 6As shown, the dust removal module monomer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com