Method for producing aluminum alloy profiles for doors and windows of high-speed trains

A technology of aluminum alloy profiles and high-speed trains, which is applied in the field of aluminum profile manufacturing, can solve the problems of unreasonable profile structures, unsatisfactory high-speed railways, unsatisfactory wind pressure resistance and sound insulation effects, etc., and achieve the effect of uniform flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

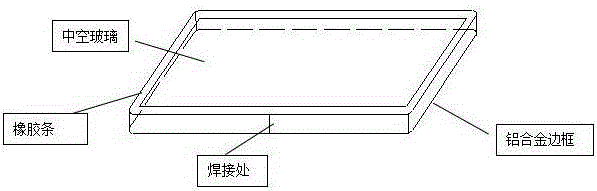

Image

Examples

Embodiment Construction

[0016] A method for producing aluminum alloy profiles for doors and windows of high-speed trains, comprising the following steps:

[0017] 1. Mold design: The size of the mold is 390mm*240mm, such a large size can increase the strength of the mold, and it is not easy to collapse; the design uses 8 diversion holes, 8 bridge positions, and a double hole in the middle, which can serve as an intermediate material supply Foot, the foreman is not easy to shift and so on. The depth of the welding chamber is 20mm, which plays the role of welding and avoids the welding line. There is no bright band on the surface after anodizing; the length of the working belt is 3mm, 4mm, 5mm, 8mm, 12mm, and different lengths can make the metal flow through the working belt. Smooth transition, uniform flow rate.

[0018] 2. Ingredients: Si: 0.2-0.6%, Fe: 0.35%, Cu: 0.1%, Mn: 0.1%, Mg: 0.45-0.9%, Zn: 0.1%, Ti: 0.1%, Al: 97.75-98.5% .

[0019] 3. Smelting: Put the raw materials in the above step 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com