Interface hermetic packaging method for electronic circuit module

An electronic circuit, hermetic packaging technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of standardized design, high efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

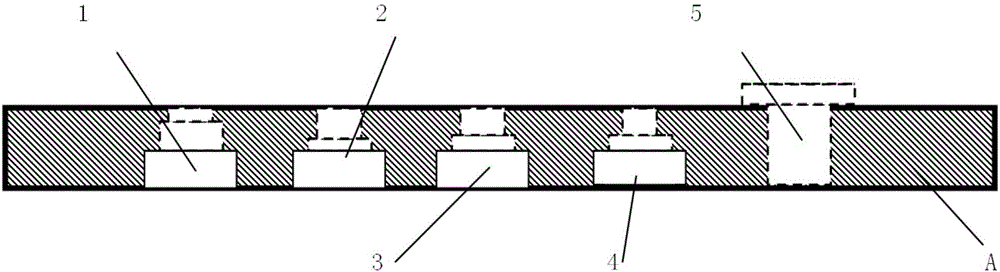

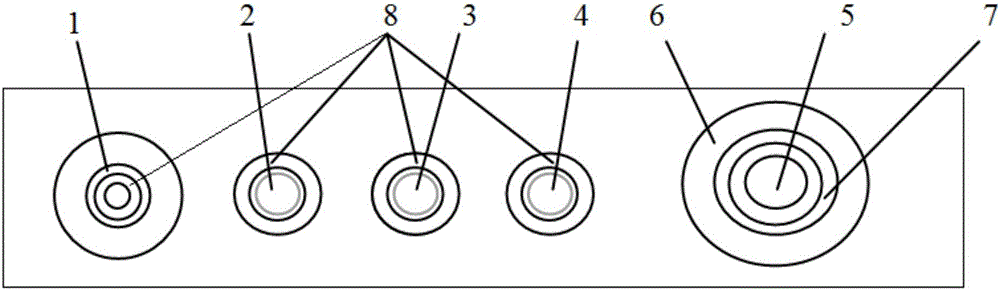

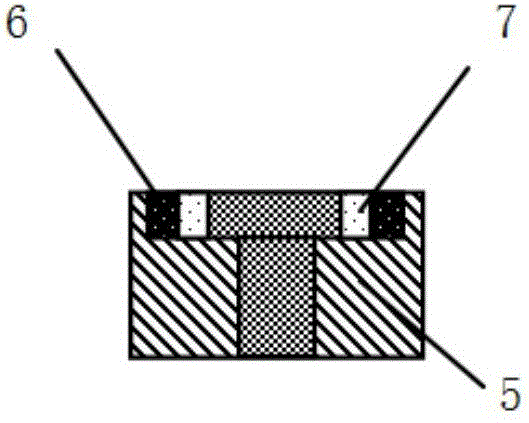

[0015] refer to Figure 1 ~ Figure 3 . According to the assembly interface of the connectors and fasteners in the electronic circuit assembly, first install the high-frequency socket 1, the first insulator 2, the second insulator 3, the third insulator 4 and the solder ring of the corresponding high-frequency socket 1; the first The solder ring of insulator 2, the solder ring of second insulator 3, and the solder ring of third insulator 4 are fixed at the positions corresponding to the preset solder ring holes 8; then the countersunk screw 5 and the shape memory alloy ring 6 are respectively assembled to their respective assembly interfaces In the vacuum welding furnace, set the welding curve that can meet the high-frequency socket 1, the first insulator 2, the second insulator 3, and the third insulator 4 at the same time, and start the welding task. When the high-frequency socket 1, the first insulator 2 After the welding of the second insulator 3 and the third insulator 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com