A four-degree-of-freedom xy galvanometer scanning device and control method

A galvanometer scanning and control method technology, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of small mirror size and angular deflection range, difficult to further improve high-frequency response characteristics, and limited scanning range. Achieve the effect of good high-frequency response characteristics, good application prospects, and large scanning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

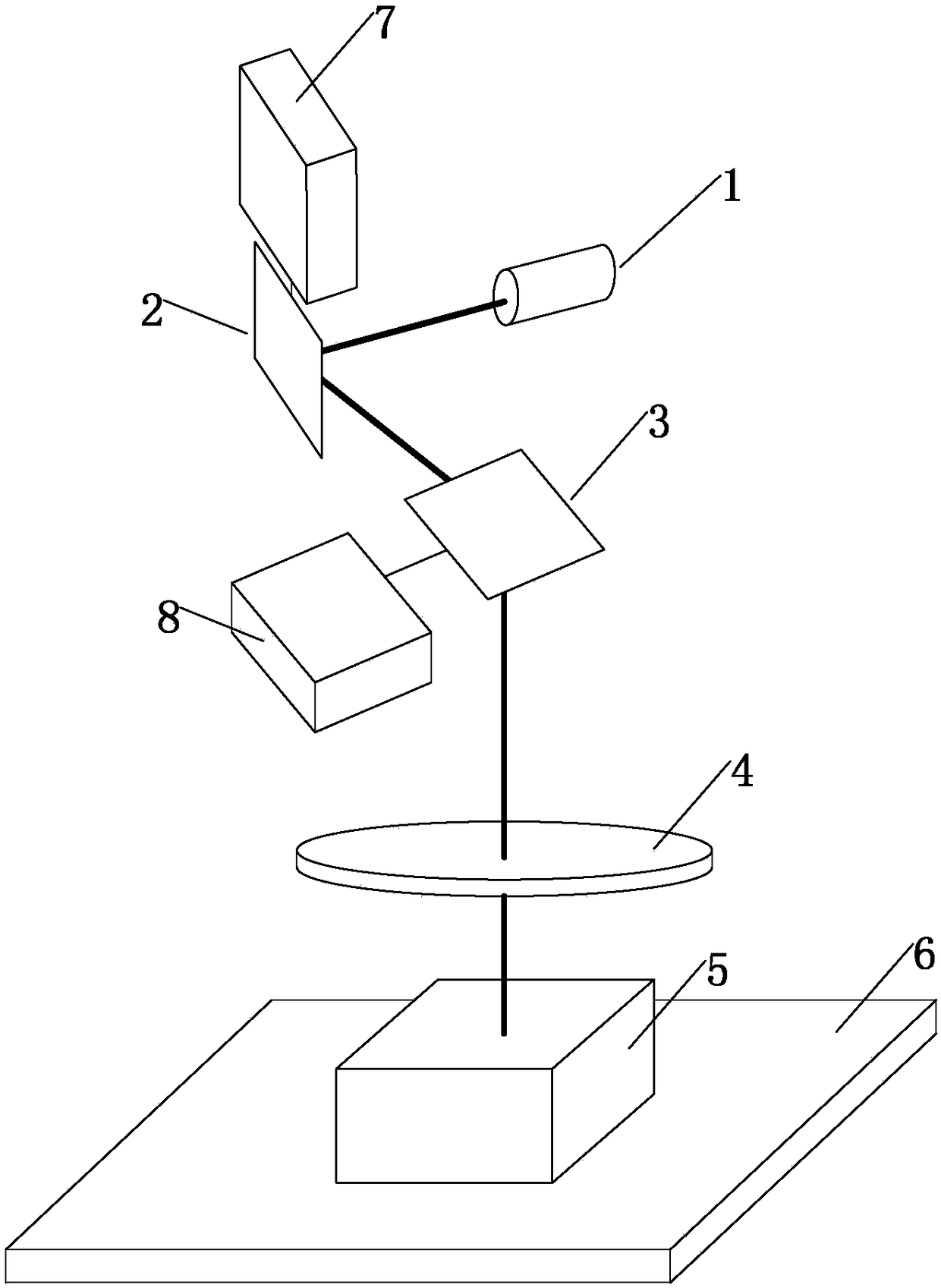

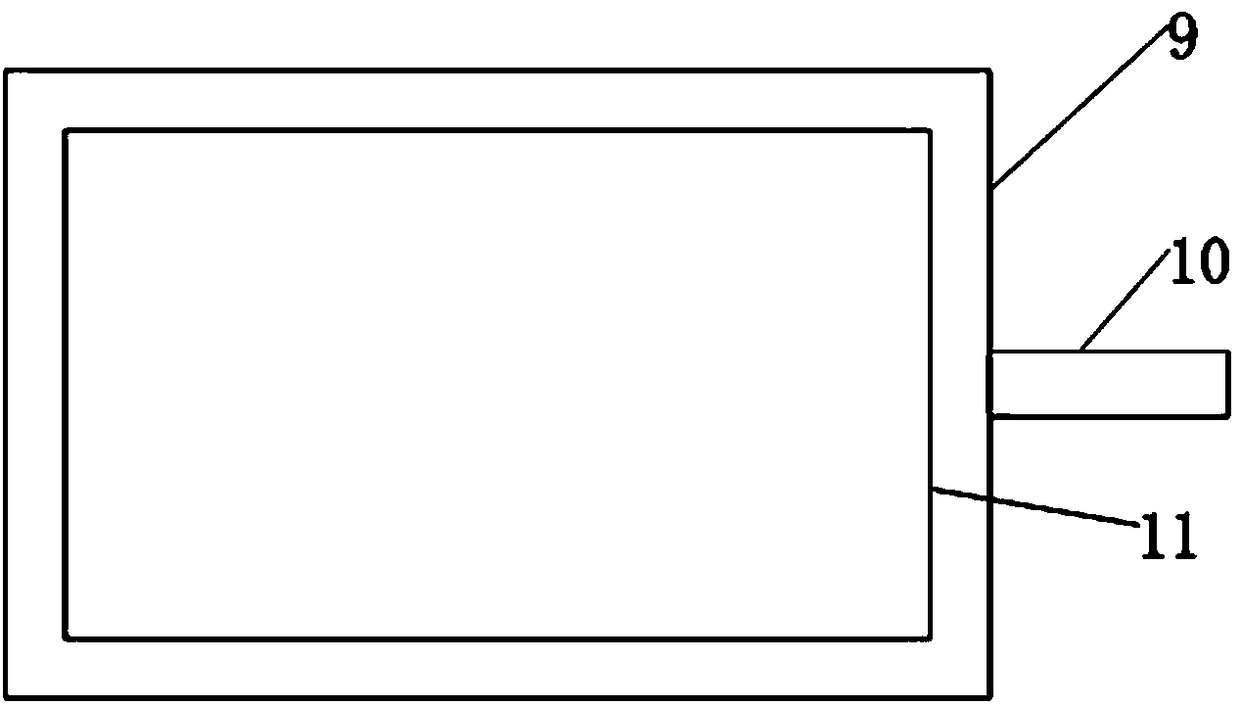

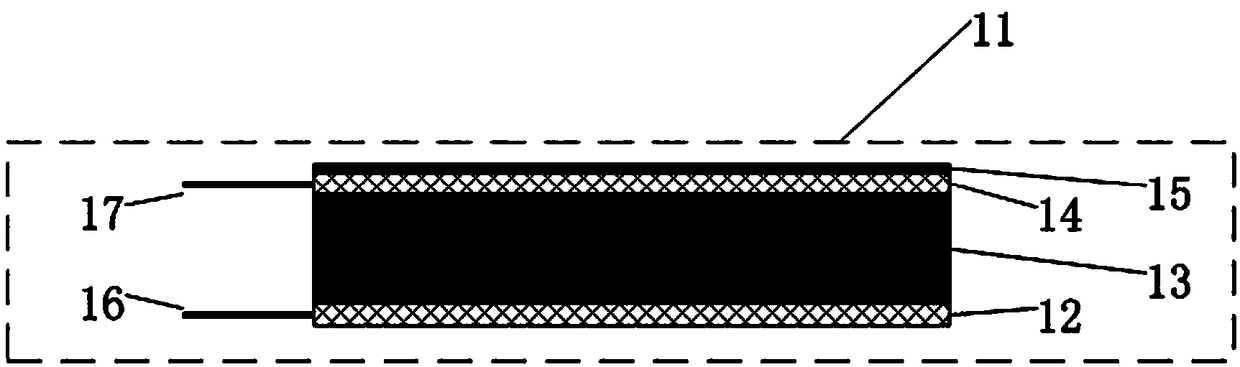

[0024] like Figure 1~5As shown, a four-degree-of-freedom XY galvanometer scanning device includes a laser 1, an XY galvanometer scanning system, a field mirror 4 and a scanning controller 18, wherein the XY galvanometer scanning system is set Above the working platform 6, the XY galvanometer scanning system includes the X-axis galvanometer mirror 2, the Y-axis galvanometer mirror 3 and the angle drive mechanism. The X-axis galvanometer mirror 2 and the Y-axis galvanometer mirror 3 adopt geometric positive Alternating layout, the angle drive mechanism includes angle servo driver 1 7 and angle servo driver 2 8, angle servo driver 1 7, angle servo driver 2 8 are connected to the scanning controller 18 respectively, X-axis vibrating mirror mirror 2 is controlled by angle servo driver 1 7 drives the deflection, and the Y-axis galvanometer mirror 3 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com