Method for preparing single crystal film

A single crystal thin film, amorphous thin film technology, applied in the field of single crystal thin film preparation, can solve problems such as crystal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a single crystal thin film, comprising the following steps:

[0030] First, an amorphous film is formed on the substrate 5 by means of PVD, CVD or solution coating on the substrate 5;

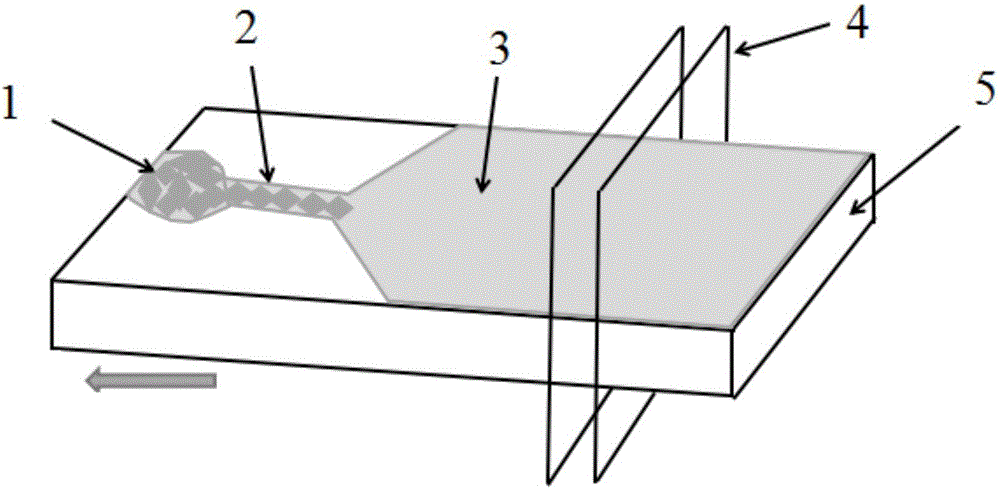

[0031] Then, the prepared amorphous film is etched to form the amorphous film figure 1 The shape shown has a region 1 for forming a polycrystalline thin film, an elongated region 2 for selectively growing a single crystal, and a region 3 for forming a single crystal thin film; the pattern can be formed by mask evaporation, or by The amorphous film is etched by solution etching method or plasma etching method, thus forming such as figure 1 The interconnected three-segment structure shown: the second region 2 is an elongated structure whose width is smaller than the minimum width for polycrystalline formation;

[0032] Finally, by means of heat treatment, laser irradiation, microwave treatment or electromagnetic radiation heating, each region of the amorphous film ...

Embodiment

[0037] First, an a-Si thin film is formed on the substrate 5 by PVD;

[0038] Then, photolithography is performed on the prepared a-Si thin film to form the figure 1 The shape shown has an interconnected three-section structure: a region 1 for forming a polycrystalline Si film, a region 2 for selectively growing a single crystal, and a region 3 for forming a single crystal Si film, wherein the second region 2 is a thin Long structures, the width of which is not more than 1cm;

[0039] Finally, by means of heat treatment, laser irradiation, microwave treatment or electromagnetic radiation heating, each region of the a-Si thin film is sequentially processed to make it gradually crystallize, and a polycrystalline Si region, a selective region and a single crystal Si film region are sequentially formed on the substrate. , and finally remove the polycrystalline Si region and the selective region to obtain a single crystal Si film.

[0040] In addition, the amorphous thin film of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com