A highly sensitive nitrogen dioxide sensor

A nitrogen dioxide, high-sensitivity technology, applied in the field of sensors, can solve the problems of YSZ substrate manufacturing difficulty and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

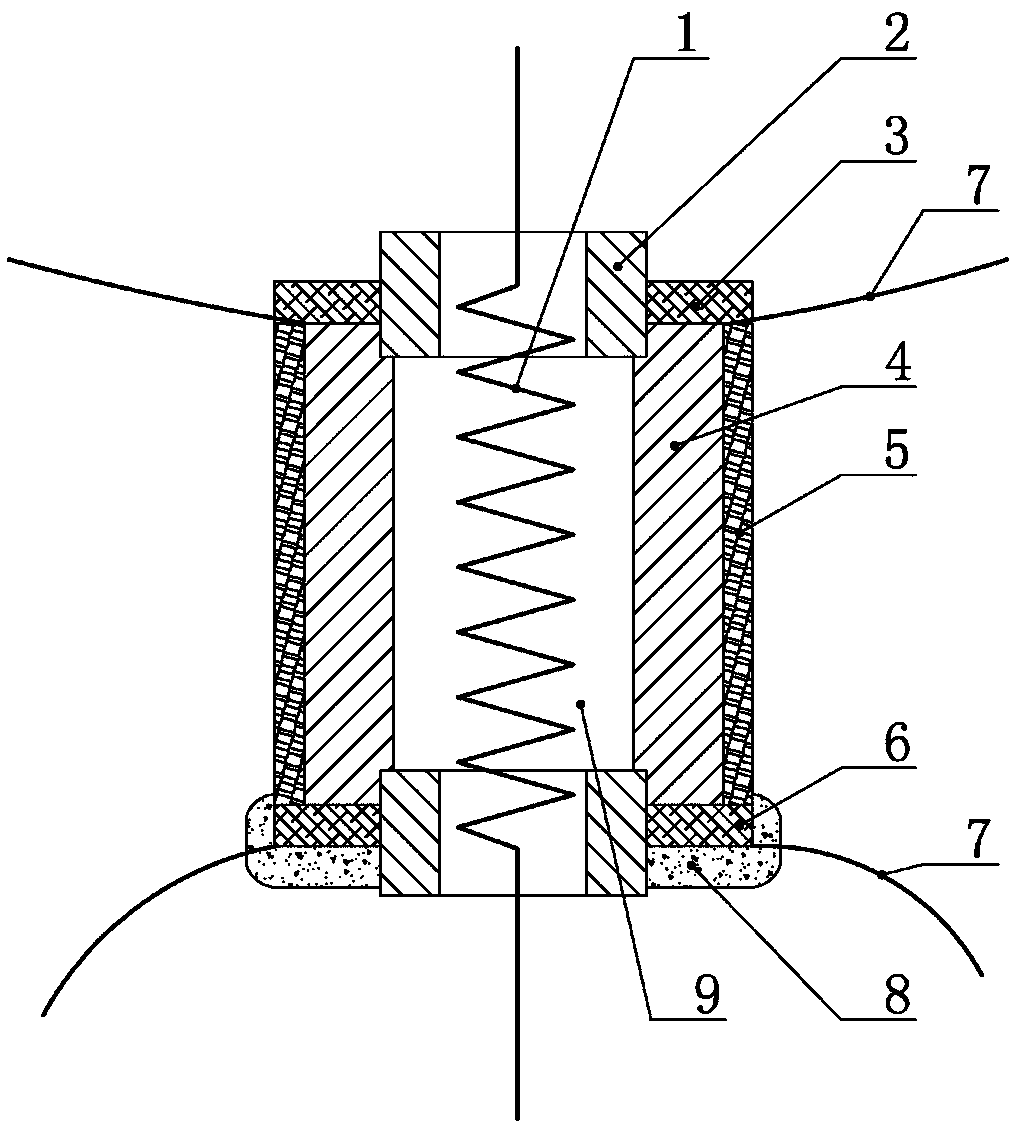

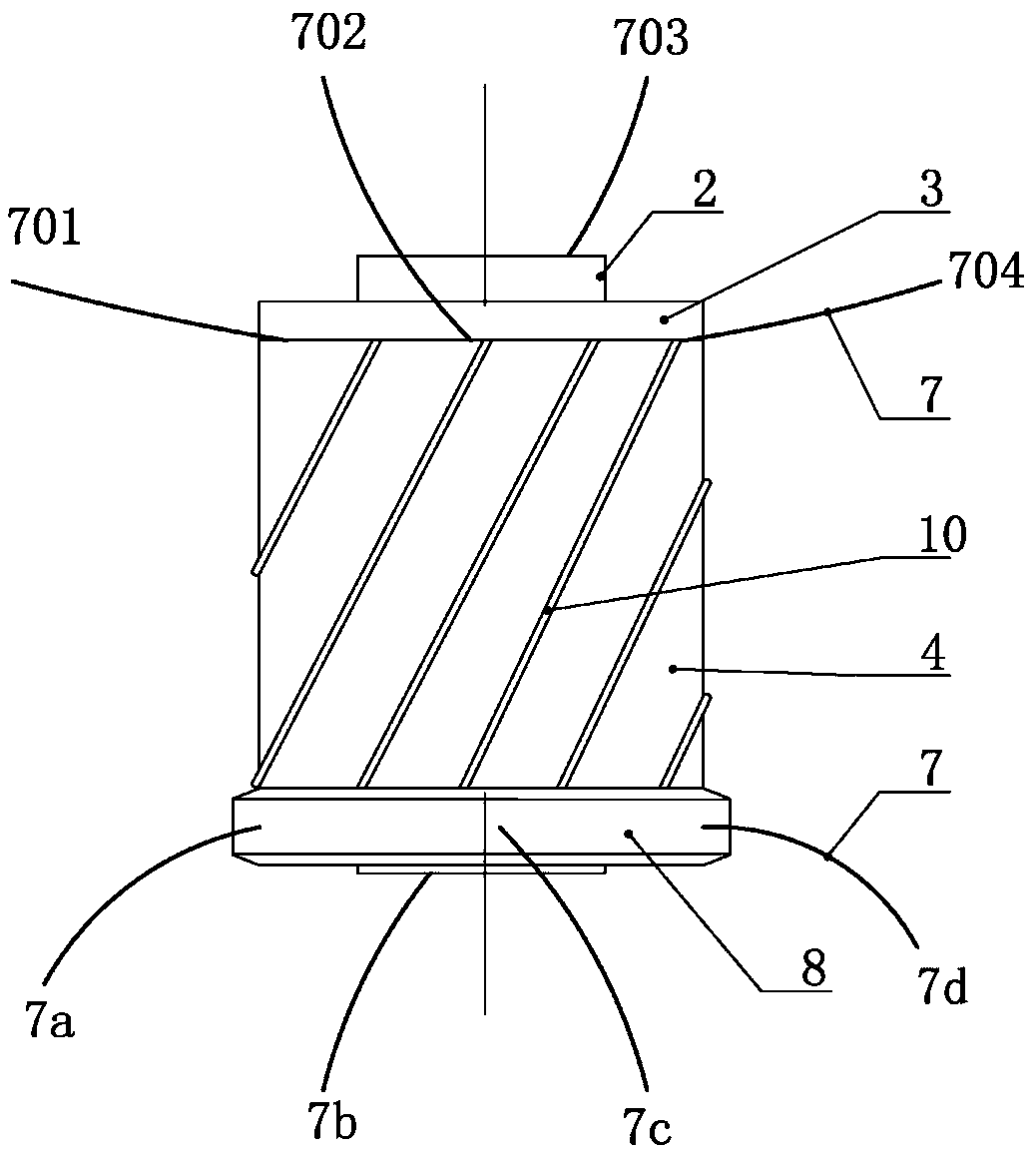

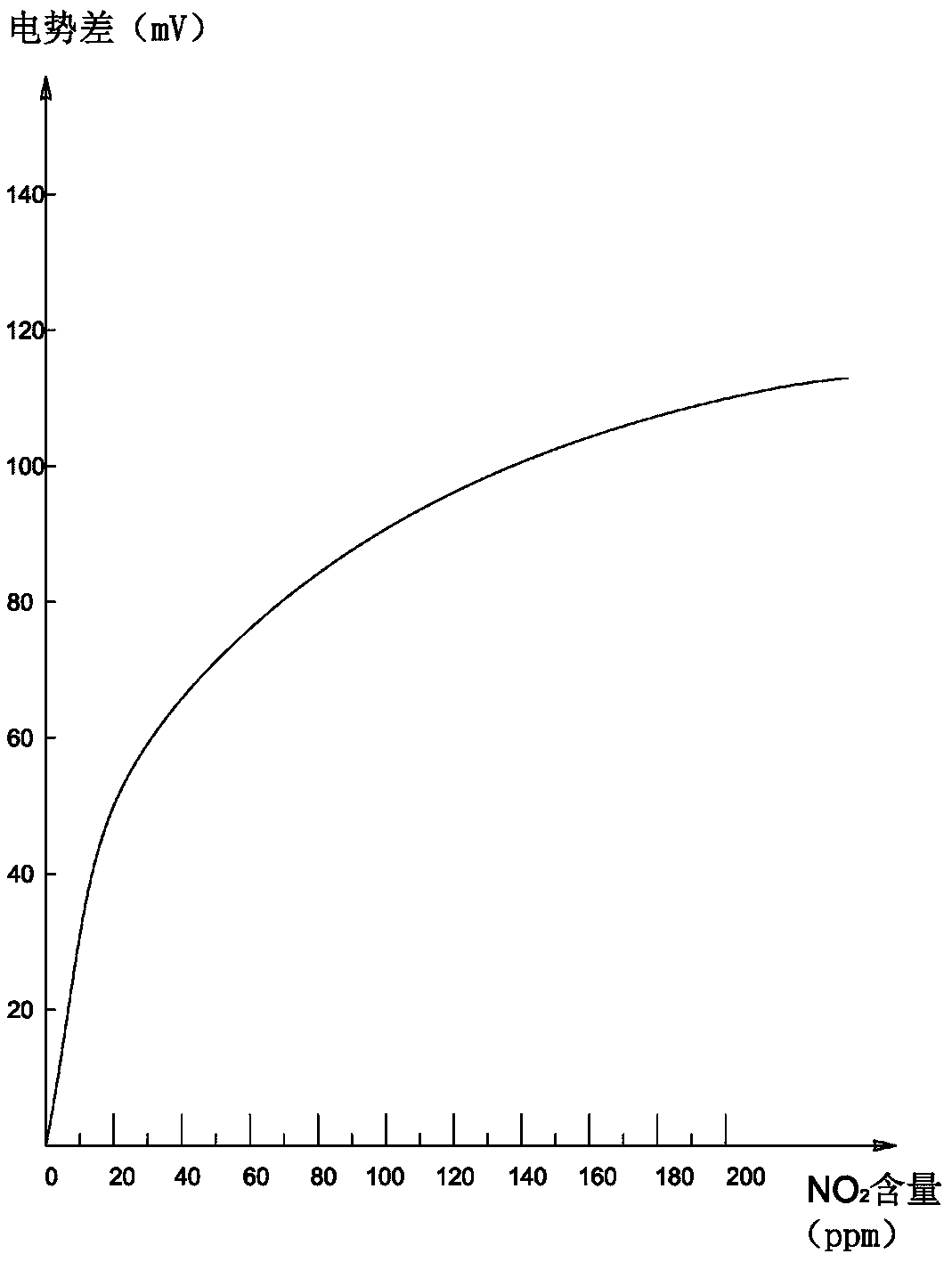

[0022] Such as figure 1 and 2 As shown, it is a highly sensitive nitrogen dioxide sensor, comprising a cylindrical ceramic tube 4 with a length of 12 mm and an outer diameter of 8 mm; ceramic end caps 2 are inserted in the center of both ends of the ceramic tube 4, and the ceramic tube 4 A spiral heating wire 1 is provided in the cavity 9, and the two ends of the spiral heating wire 1 are led out from the center hole of the ceramic end cap 2 through wires, and an Au reference electrode 3 is arranged on the end surface of one end of the ceramic tube 4, and an Au reference electrode 3 is provided on the other end of the ceramic tube 4. Au working electrode 6 is arranged on the end surface, and Au working electrode 6 is covered with TiO sensitive electrode 8, and Pt lead wire 7 is respectively drawn out from reference electrode 3 and working electrode 6, and the outer periphery of ceramic tube 4 is provided with nanometer indium tin oxide. The sprayed sintered layer 5 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com