Nitriding method of substrate and preparation method of gallium nitride buffer layer

A gallium nitride buffer layer and substrate technology, applied in the field of microelectronics, can solve the problems of increasing the number of molecular collisions, high chamber pressure, and increasing buffer layer defects, so as to increase bombardment, expand the nitride window, and reduce the buffer layer The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The specific implementation method of using ICP equipment to carry out nitriding treatment is as follows:

[0043] Introduce nitrogen gas into the reaction chamber, and turn on the power supply of the upper electrode and the power supply of the lower electrode. Under the action of the upper electrode power supply and the lower electrode power supply, the nitrogen gas in the reaction chamber is ionized to generate N ions and N atoms, which are accelerated, and the high-energy N ions pair Al 2 o 3 The substrate surface is bombarded, effectively opening Al-O bonds. At the same time, some N atoms and Al 2 o 3 The substrate mainly undergoes the following reactions, namely:

[0044] al 2 o 3 +N 2 →AlN+O

[0045] N atoms and Al 2 o 3 The reaction replaces Al 2 o 3 O atoms in, and in Al 2 o 3 A stable AlN layer is formed on the surface of the substrate.

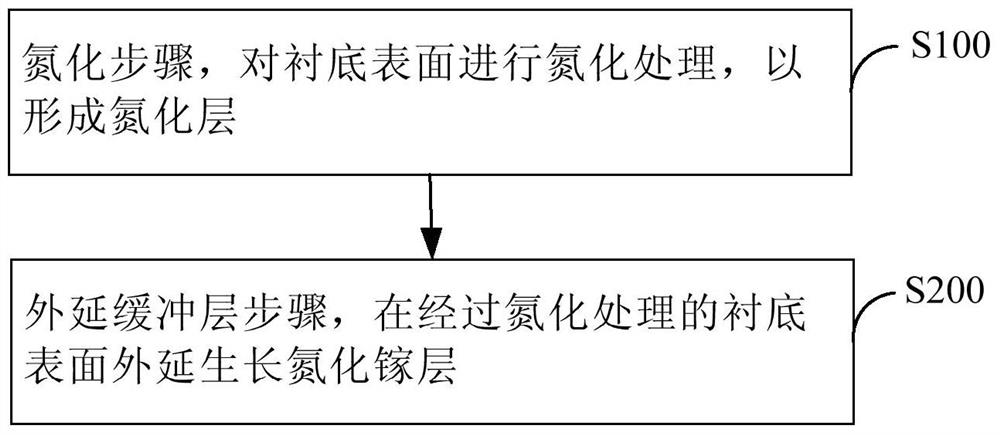

[0046] As another technical solution, figure 2 A flow chart of the preparation method of the gallium nitrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com