Wheat flour substitute rice flour, and method for manufacturing gluten-free rice flour bread

A production method and technology of rice flour, applied in the direction of dough preparation, pre-baked dough treatment, legume baked food, etc., can solve the problems of unestablished production technology, insufficient expansion degree, difficulty in making bread, etc., and achieve good taste and full Expansion, fine texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

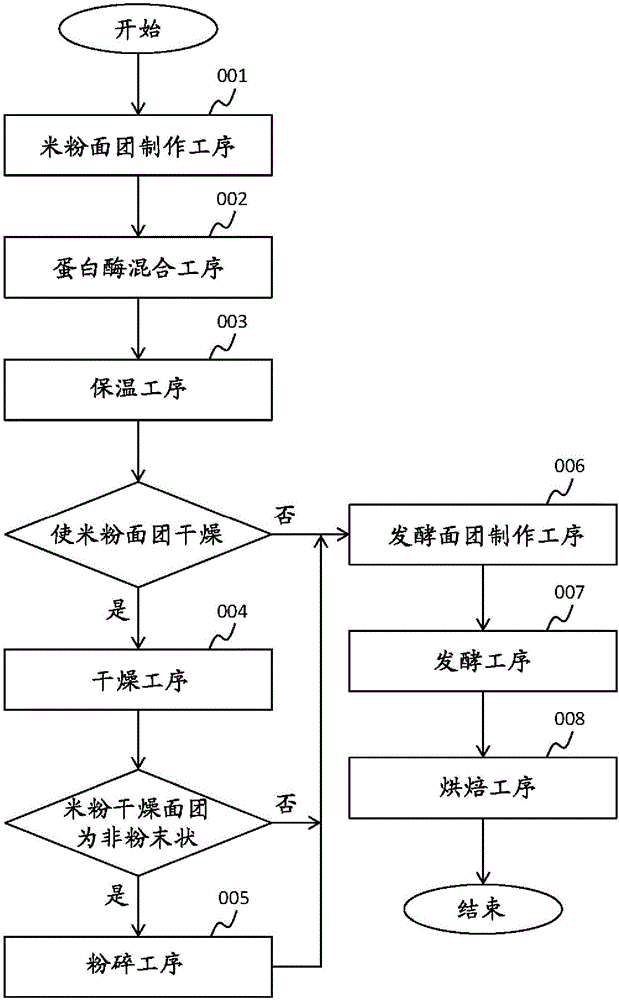

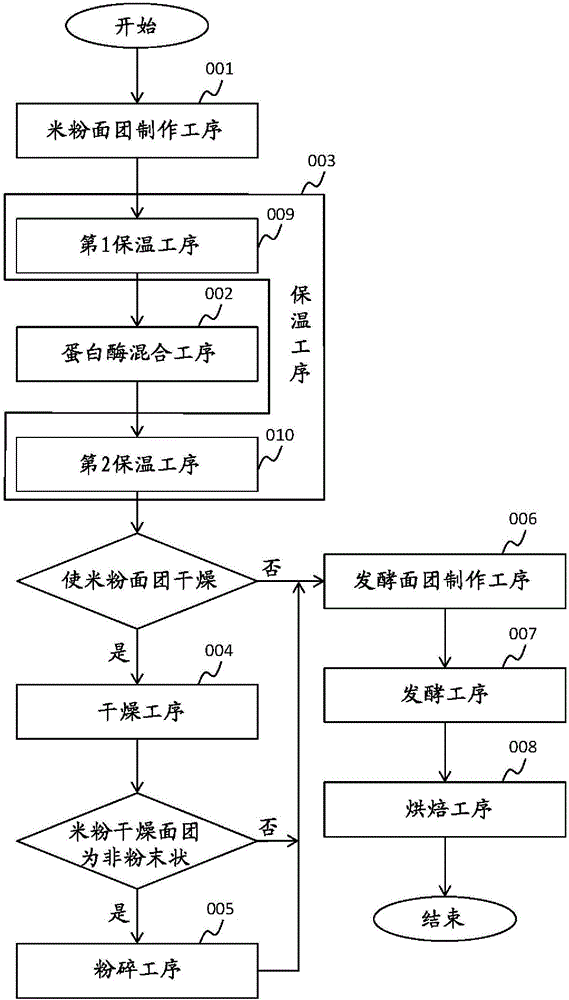

Method used

Image

Examples

Embodiment 1

[0162]

[0163] (Purpose)

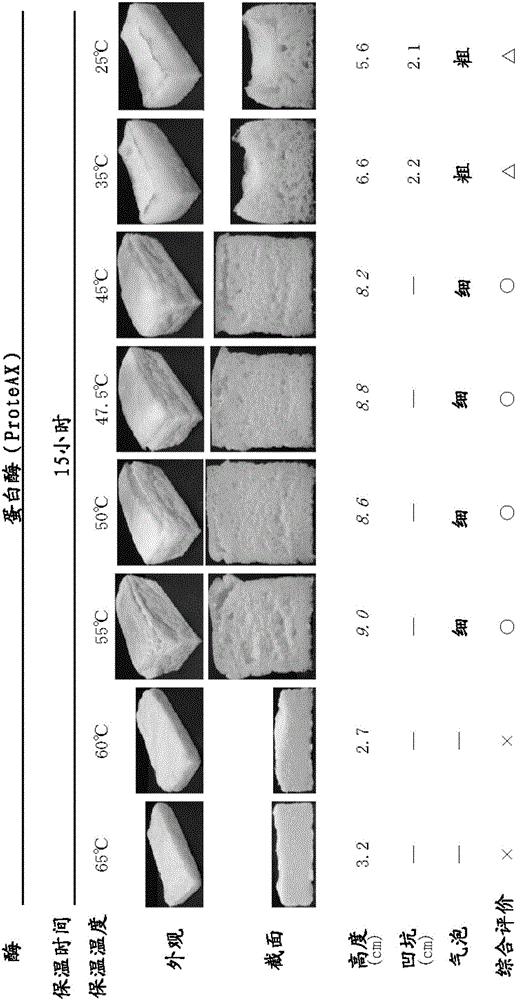

[0164] The relationship between the protease treatment temperature and the expansion properties of 100% rice flour bread produced using the treated rice flour was examined.

[0165] (method)

[0166] Add 210mL of water and 150U / mL of protease to 210g (14% of flour moisture content) of white rice flour (rice variety "Koshihikari"), and knead for 3 minutes with a household mixer (THM280 or THM281, Tescom) to make a dough.

[0167] As a protease, Aspergillus-derived ProteAX (Amano Enzyme) or Bacillus-derived Thermoase (Amano Enzyme) was used. Then, add described protease to the rice flour dough of making, with 25 ℃, 35 ℃, 45 ℃, 47.5 ℃, 50 ℃, 55 ℃, 60 ℃ and 65 ℃ in incubator (MIR-254, Sanyo Electric; only Incubation was carried out at 65°C for 15 hours using ND-420 (Tokyo Rikan Instruments). Each protease was added so that the protease activity in 1 mL of rice flour dough became 150 U. Add 10 g of sugar, 3 g of salt, and 3 g of dry yeast (ルサッフル) t...

Embodiment 2

[0172]

[0173] (Purpose)

[0174] The relationship between the protease treatment time and the swelling properties of 100% rice flour bread produced using the treated rice flour was examined.

[0175] (method)

[0176] The basic method is based on Example 1. Among them, the following points are different from Example 1: "こなだもん" was used as the rice variety, the protease treatment temperature of ProteAX was set to 55°C, and the treatment temperature was set to 2 hours, 6 hours and 15 hours.

[0177] (result)

[0178] show the result in image 3 . As a tendency, the longer the processing time, the more 100% rice flour bread with good overrun and fine texture can be produced. A sufficient degree of expansion was not obtained with a treatment time of 2 hours, and the texture was rough. Based on the above results, the protease treatment time in the method of treating rice flour with protease of the present invention is set to 3 hours or more and 20 hours or less.

Embodiment 3

[0179]

[0180] (Purpose)

[0181] Using the protease-treated rice flour dough of the present invention prepared based on various proteases from various biological species to make 100% rice flour bread, its expansibility and fine texture were verified.

[0182] (method)

[0183] The basic steps are based on Example 1. Specifically, it is as follows. Add 210mL of water and various proteases to 210g (moisture content of flour converted to 14%) of white rice flour (rice variety "こなだもん"), and knead for 3 minutes with a household mixer (THM280 or THM281, Tescom) to make Made rice flour dough (rice flour dough making process and protease mixing process).

[0184]Each protease was added separately, and ProteAX (derived from Aspergillus, Amano Enzyme) was added so that the protease activity in 1 mL of rice flour dough became 150 U, and Protease A (derived from Aspergillus, Amano Enzyme) was added so that the protease activity in 1 mL of rice flour dough became 150 U, and protease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com