Assembly line fruit-vegetable circulating operation system

A cyclic operation and assembly line technology, which is applied in the field of agricultural equipment, can solve problems such as reduced operation efficiency and reduced planting density, and achieve the effects of increasing yield, increasing planting density, and improving labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

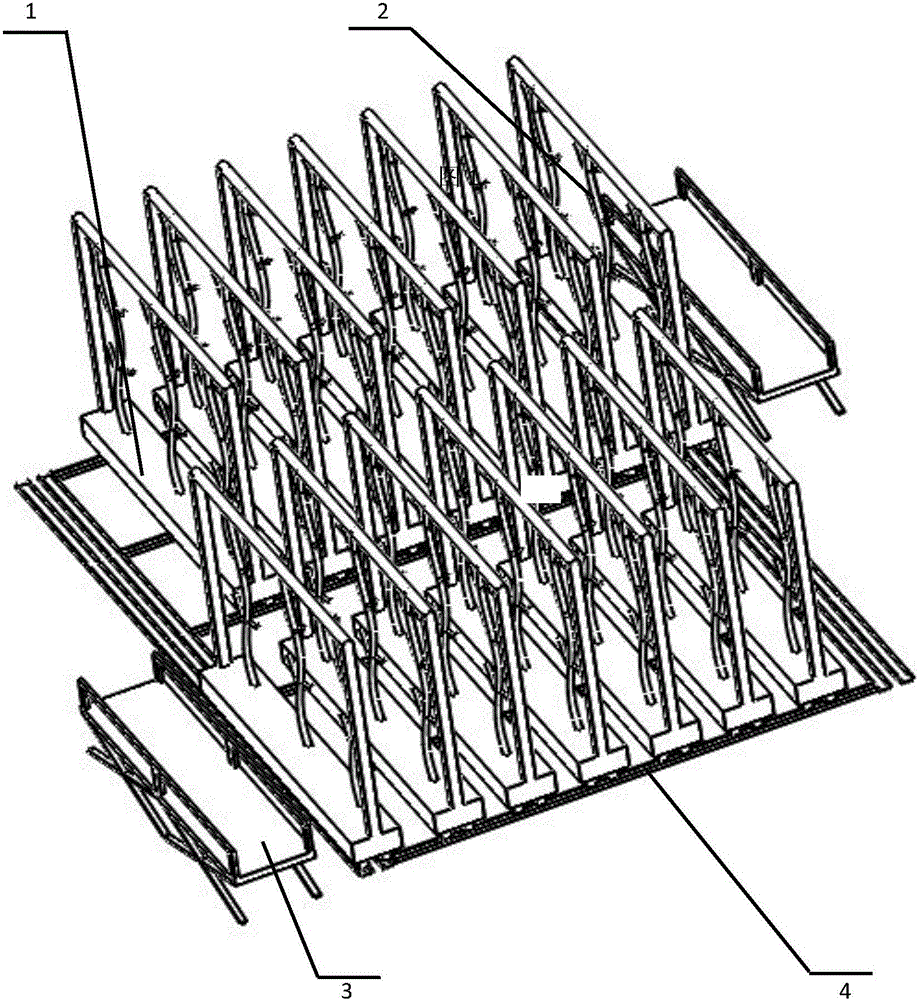

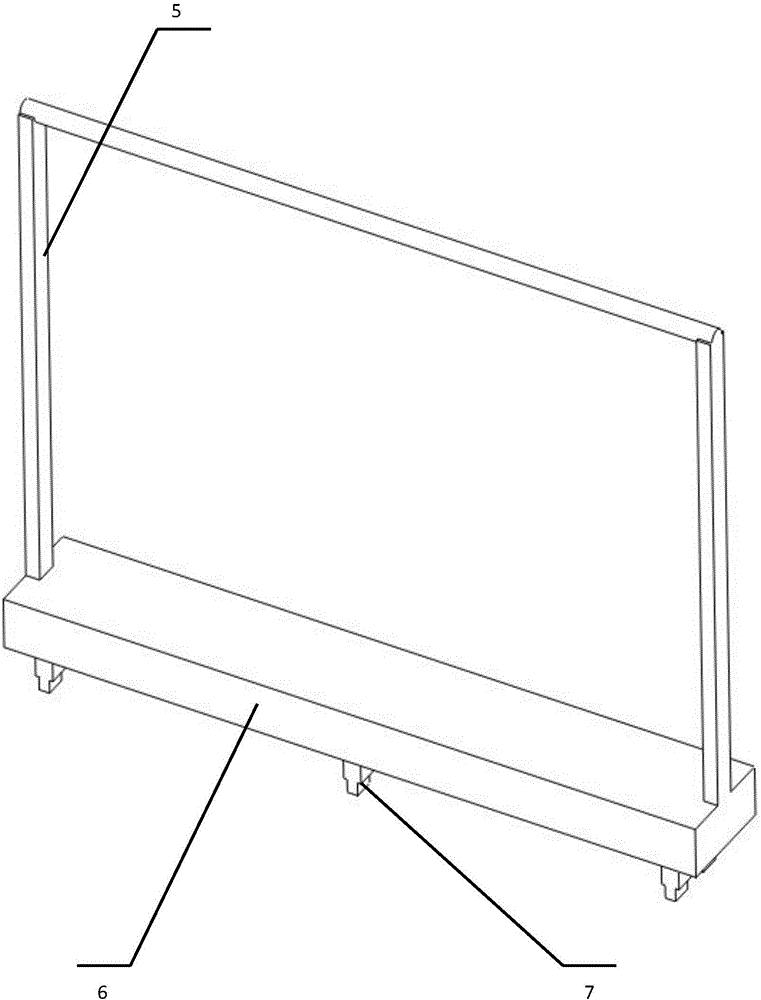

[0018] like figure 1 and figure 2 As shown, the inside of the planting tank 6 is filled with nutrients required for planting, and the fruits and vegetables are cultivated therein. Along with the growth of the fruits and vegetables, the growth support 5 installed on the planting tank 6 fixes the fruit and vegetable vines 2 . Simultaneously, the planting tank 6 is installed on the mobile tractor 7, and the planting tank 6 and the plants and the growth support 5 thereon are driven by the movement of the mobile tractor 7 to complete the longitudinal and lateral movement along the moving slide rail 4.

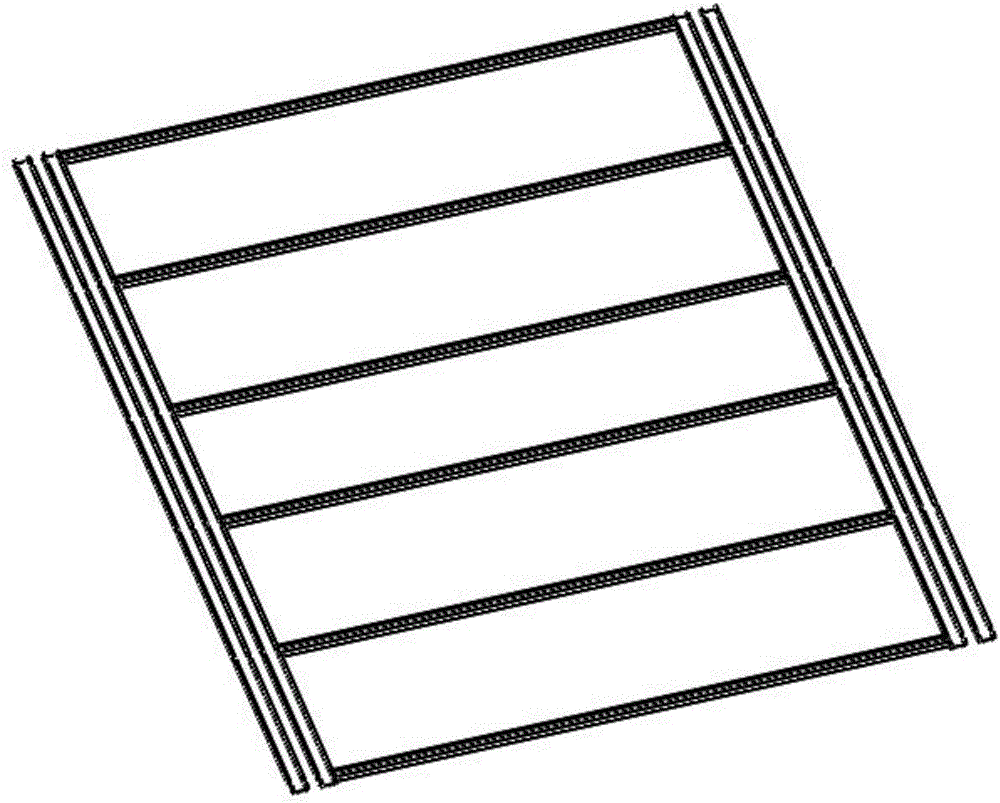

[0019] like figure 1 and image 3 As shown, the mobile slide rail 4 is installed on the ground of the greenhouse, and it realizes the lateral guidance and the longitudinal guidance of the movement of the planting platform 1 .

[0020] like figure 1 and Figure 4 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com