Portable impurity-removing wastewater recovery apparatus having backwashing

A waste water recycling and backwashing technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of high cost of use, large amount of replacement of filter screens, time-consuming and labor-intensive problems, and achieve low production costs, The effect of increasing the service life and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

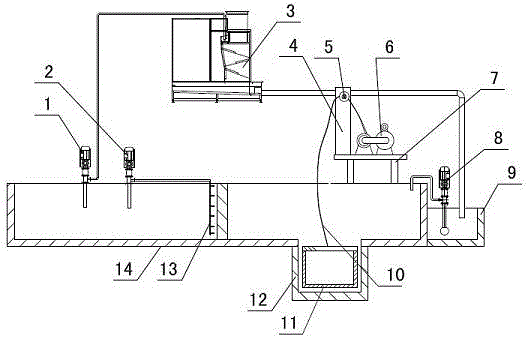

[0015] Such as figure 1 , figure 2 As shown, the portable waste water recovery device with backwashing and impurity removal described in this embodiment includes a waste water pool 14 with filtration and a rust removal mechanism 3, and a collection pool 9 is arranged on the right side of the waste water pool 14, and the collection pool 9 is drained The pipeline is connected to the 3 outlets of the derusting mechanism, and the clean water place of the waste water pool 14 is connected to the 3 water inlets of the derusting mechanism through the water inlet pipeline. A clear water delivery pump 1 is installed on the water inlet pipeline, and the collection pool 9 communicates with the water inlet of the derusting mechanism through the delivery pipeline. The right side of the waste water pool 14 is connected, a submersible sewage pump 8 is installed on the delivery pipeline, a workbench 7 is arranged on the top of the waste water pool 14, a support frame 4 is arranged on the work...

Embodiment 2

[0019] In this embodiment, further changes are made on the basis of the first embodiment, the groove depth of the cleaning tank 11 is changed to 45 mm, the diameter of the leakage hole is changed to 1 mm, and the distance between adjacent leakage holes is changed to 30 mm. Others are the same as embodiment one.

Embodiment 3

[0021] In this embodiment, further changes are made on the basis of the first embodiment, the groove depth of the cleaning tank 11 is changed to 60 mm, the diameter of the leak hole is changed to 2 mm, and the distance between adjacent leak holes is changed to 60 mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com