Absorption and water solution flushing and purifying ventilator for chimneys, workshops, shaft pollution and intersection tail gas

A technology of crossroads and exhaust gas absorption, which is applied in the directions of gas treatment, the use of liquid separation agents, chemical instruments and methods, etc., can solve the problems of inability to realize the installation of purification equipment, high pollutants, and high equipment costs, and achieves simple structure and high efficiency. Air Quality, Appearance and Practical Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

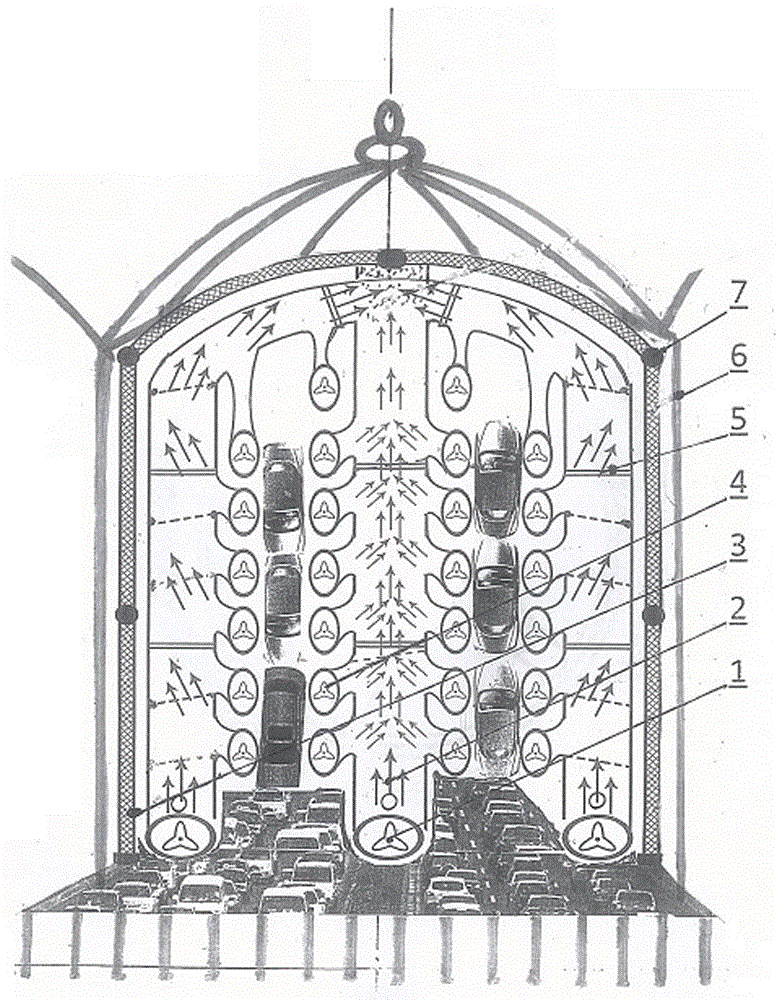

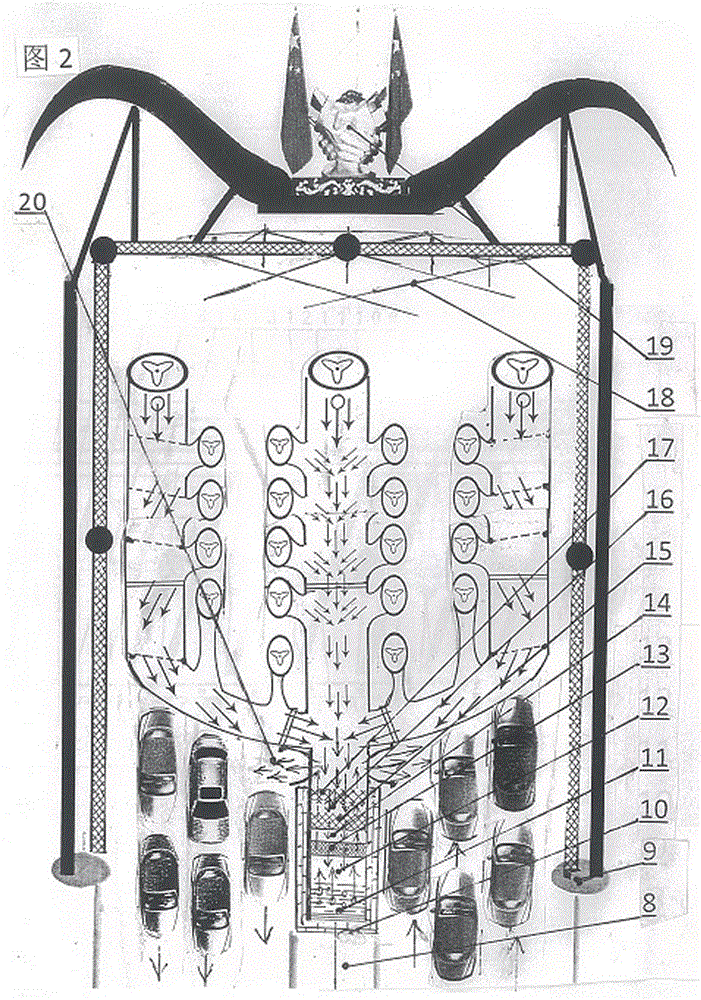

[0017] Such as figure 1 and figure 2 The present invention provides a chimney workshop mine polluted crossroads tail gas absorption aqueous solution flushing purifying ventilator, this embodiment is really at the crossroads. Including a shed-shaped suction hood 3, the interior of the suction hood is provided with a number of column-type aspirators 1, and a number of suction fans 4 are arranged on the aspirator. The aspirator is connected to the exhaust gas channel on the top, and the exhaust gas channel extends horizontally The aspirator is connected horizontally, and the end of the waste gas channel is connected to the purification pool 10 . The purification tank includes a purification liquid located at the bottom, and above the purification liquid is a waste gas storage chamber 12, above which there are several spray layers in sequence. The machine sprays from top to bottom.

[0018] In this embodiment, the exhaust gas passage extending laterally is provided with an air...

Embodiment 2

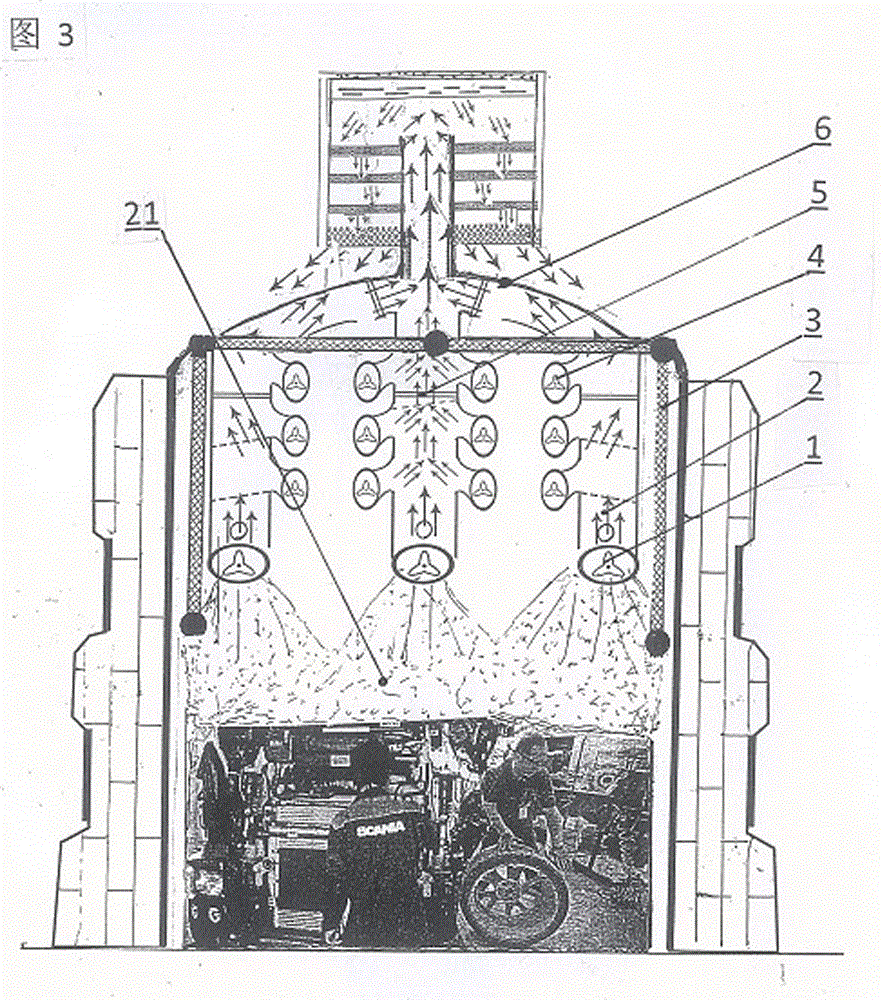

[0036] This embodiment is an implementation schematic diagram of installing the device in a mine or an operation workshop. In this embodiment, the purification pool is located above the exhaust port of the mine or above the exhaust port of the operation workshop. The waste gas in the exhaust port is discharged upwards and enters the interior of the purification pool through the pipeline. The unpurified gas 21 flows from the spray layer around the pipeline. After filtration, it is discharged to the outside world through the outlet.

Embodiment 3

[0038] Such as Figure 4 As shown, this embodiment is a schematic diagram of centralized absorption and purification arranged in a chimney, and the device is independently arranged on the top of the chimney 22 and fixed with the top of the chimney. The fixed canopy 23 is to cover the smog collection device, the bottom is provided with suction fan, both sides can stretch up and down, protect the protection device that the suction fan can go up and down under the bad weather of strong wind and heavy rain, the suction fan is controlled by the exhaust pipe. The exhaust gas is sent from top to bottom into the interior of the purification tank for purification and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com