A tube coiler and method for coiling a separation column

A separation column and tube rolling machine technology, applied in the field of machining, can solve the problems of coiling spiral tubes and the inability to arrange the coils of spiral objects closely, and achieve the effects of low cost, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

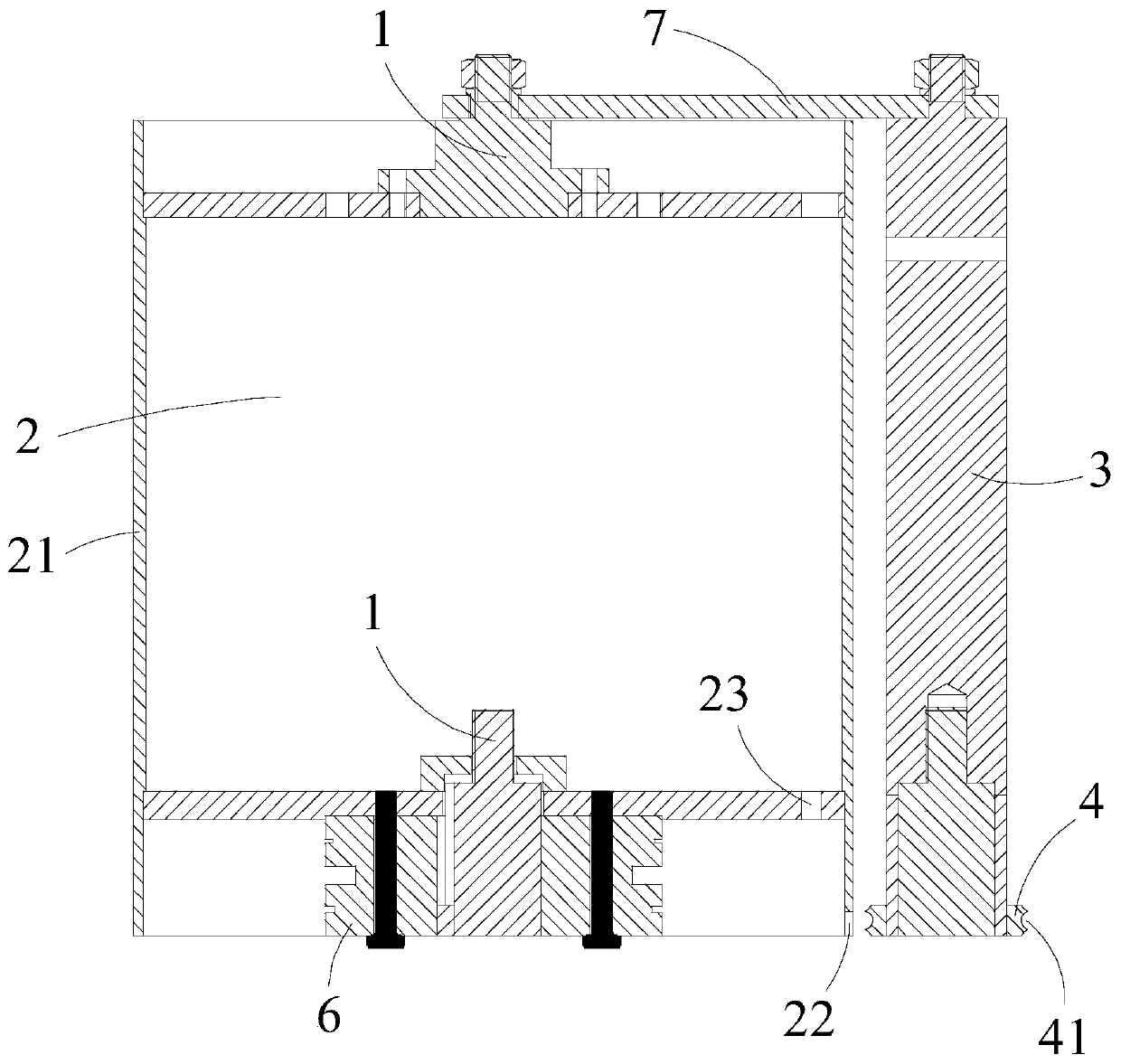

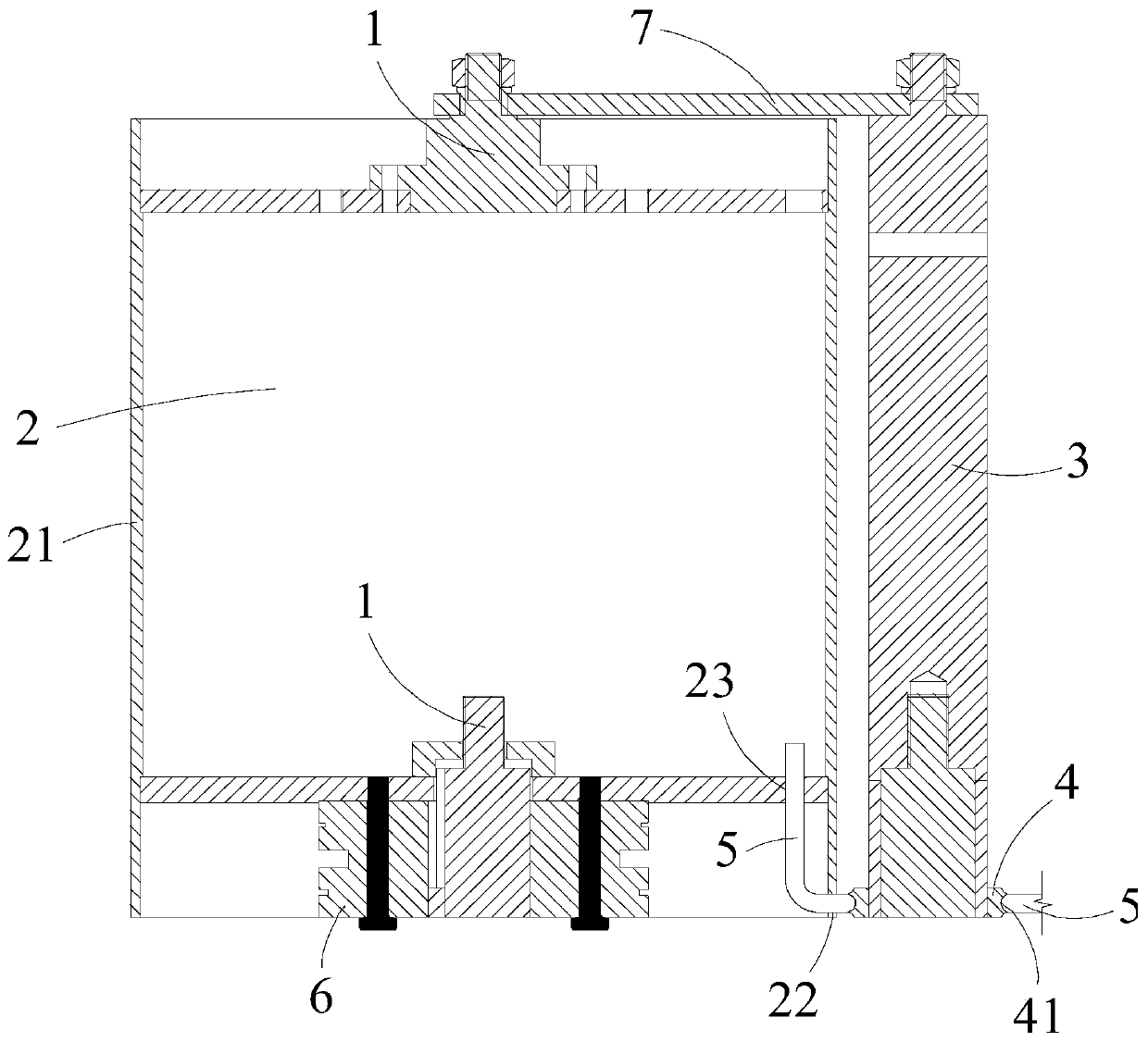

[0049] Such as Figure 1-3 As shown, a pipe coiler for rolling a separation column according to the present invention includes a frame, and the frame is provided with a rotating shaft 1, and also includes:

[0050] The rolling module 2 is rotatably connected to the rotating shaft 1, and includes a sleeve 21 and a bayonet port 1 22, the sleeve 21 is used for winding the hollow straight pipe 5 on its side wall, and the bayonet port 1 22 is used for fixing One end of the hollow straight pipe 5, the card interface 1 22 is arranged on the side wall of the sleeve 21;

[0051] The driving device is connected to the rolling module 2 and drives it to rotate around the rotating shaft 1;

[0052] The guide shaft 3 is arranged parallel to the rotating shaft 1;

[0053] The guide wheel 4 is slidably arranged on the guide shaft 3 and rotates around the guide shaft 3 . The guide wheel 4 is provided with a guide groove 41 , and the guide groove 41 is adapted to the hollow straight pipe 5 . ...

Embodiment 2

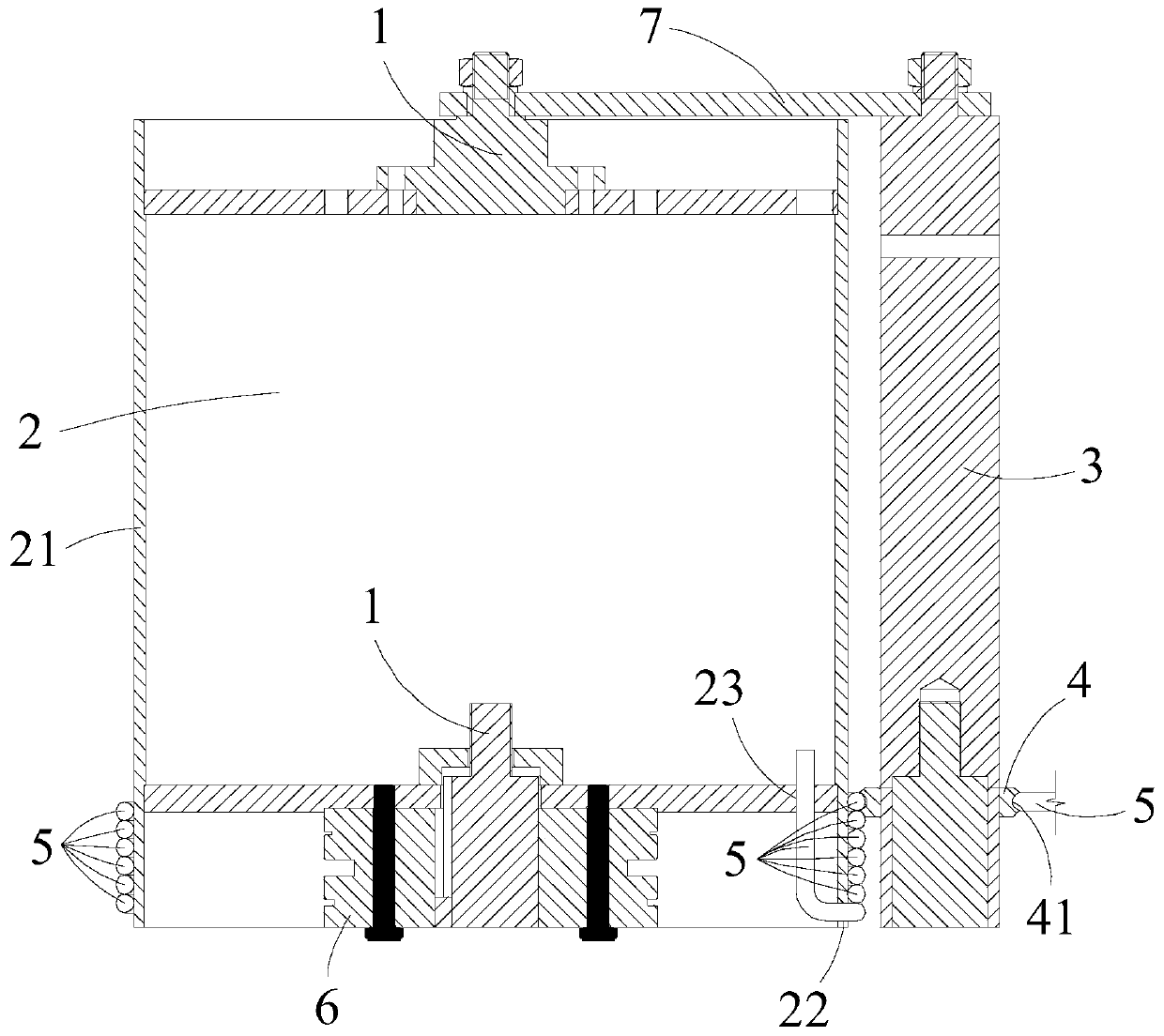

[0060] Such as Figure 1-3 As shown, a method for rolling a separation column according to the present invention uses a tube coiler for rolling a separation column as described in Example 1, which is characterized in that it includes the following steps:

[0061] A. Fix one end of the hollow straight pipe 5 to the card interface one 22, and the body of the hollow straight pipe 5 is adapted to the guide groove 41;

[0062] B. Start the driving device, and the hollow straight pipe 5 is wound on the sleeve 21 to form a helical pipe;

[0063] C, welding the rings formed by the hollow straight tubes 5 of the two adjacent plates;

[0064] D. The spiral tube is demoulded.

[0065] As a preferred solution of this embodiment, the step C is implemented while the step B is implemented.

[0066] Using a method for rolling a separation column according to the present invention, through the mutual cooperation of the rolling module 2, the driving device, the guide shaft 3 and the guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com