Pipe box loose lining structure and manufacturing method thereof

A manufacturing method and tube box technology, applied in the direction of manufacturing tools, welding equipment, auxiliary devices, etc., can solve problems such as liner vibration, liner weld fatigue failure, etc., and achieve the effect of easy control and prevention of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

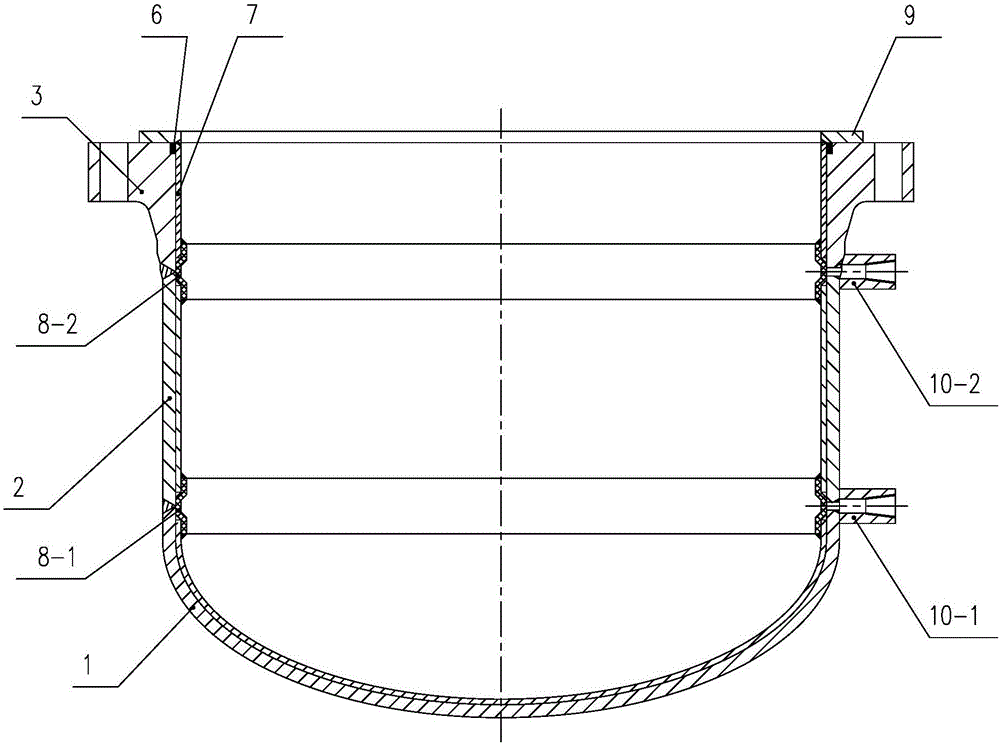

[0030] Such as figure 1 The shown pipe box loose lining structure includes a circular cylinder 2 with two ends open, a head 1 welded on one end of the cylinder 2 and a flange 3 welded on the other end of the cylinder 2, the head 1 and cylinder 2 are both made of composite plates made of rare metals and steel plates, the flange 3 is a steel flange, the inner wall of the flange 3 is attached with a liner 7, and the top of the flange 3 is set There is a welding ring 9, the inner side of the welding seam of the head 1 and the cylinder 2 is provided with a first protective cover 8-1, and the inner side of the welding seam of the cylinder 2 and the flange 3 is provided with a second protective cover 8 -2, the first leak detection hole is opened at the welding seam of the head 1 and the cylinder body 2, and the first leak detection hole communicates with the first leak detection nozzle 10-1, and the welding of the cylinder body 2 and the flange 3 There is a second leak detection hol...

Embodiment 2

[0035] The manufacturing method of the pipe box loose lining structure of the present embodiment comprises the following steps:

[0036] Step 1. Put the head 1 (material: titanium steel composite plate, the thickness of the titanium cladding layer is 3mm, the specification is: inner diameter 600mm, thickness 18mm), cylinder 2 (material is titanium steel composite plate) and flange 3 (material It is: steel, the specification is: inner diameter 606mm) grouping, after the grouping is completed and the error variable is detected to meet the requirement of "error variable ≤ 1.5mm", the head 1 is welded to one end of the cylinder body 2, and the flange 3 is welded to the cylinder The other end of body 2;

[0037] 100% RT non-destructive testing is carried out after welding. After testing, the welding conforms to NB / T47013.2-2015 Class I or Class II;

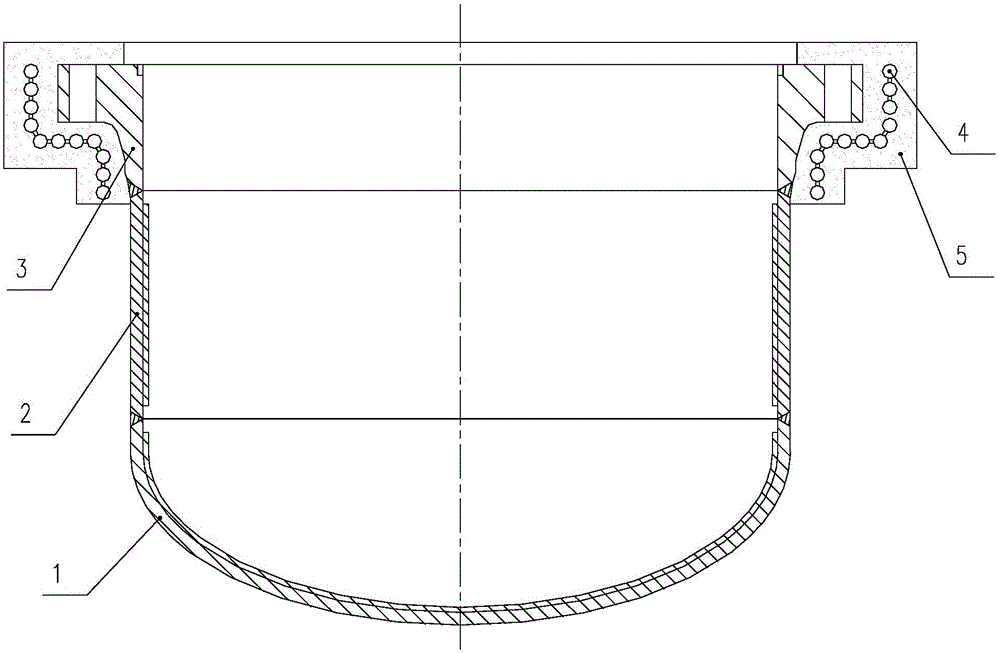

[0038] Step 2: Wrap the electric heating track 4 evenly on the outer wall of the flange 3, then use the thermal insulation cotton 5 ...

Embodiment 3

[0044]The difference between the manufacturing method of the pipe box loose lining structure in this embodiment and that of Embodiment 2 is that in all parts made of composite plates, the layers of rare metal materials are replaced by titanium alloys, tantalum, and tantalum. alloy, zirconium, zirconium alloy, niobium or niobium alloy. In all rare metal parts, the material is replaced by titanium alloy, tantalum, tantalum alloy, zirconium, zirconium alloy, niobium or niobium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com