Device and method for carrying out parallel processing of scattering net points of light guide plates through femtosecond lasers

A femtosecond laser and light guide plate technology, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of low processing efficiency and achieve the effect of improving efficiency, improving precision, and maintaining stable processing quality and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

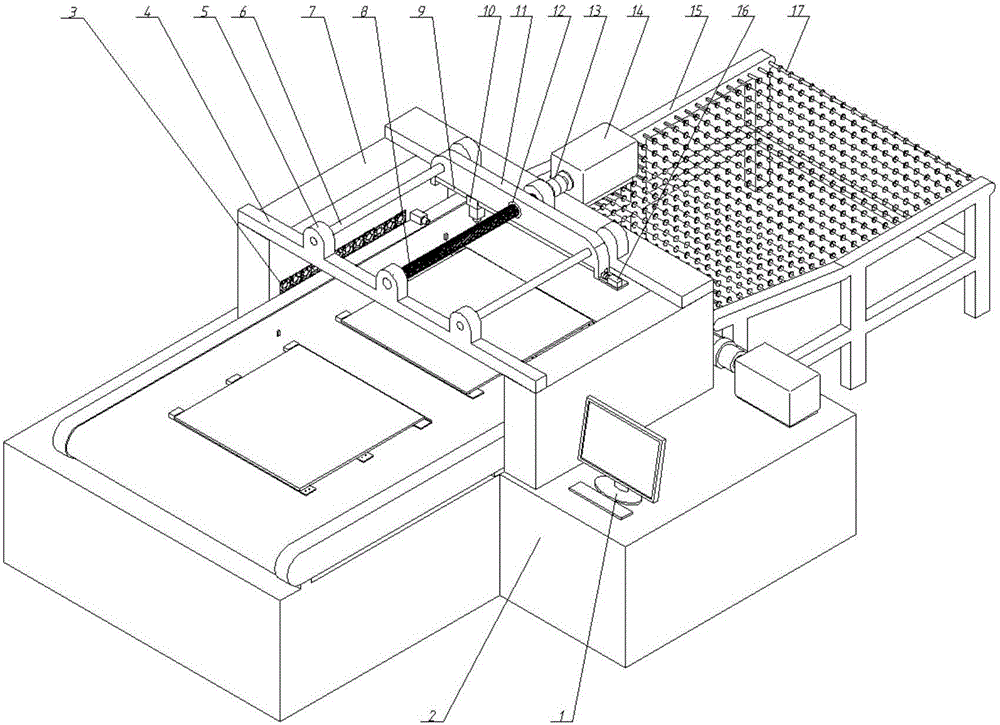

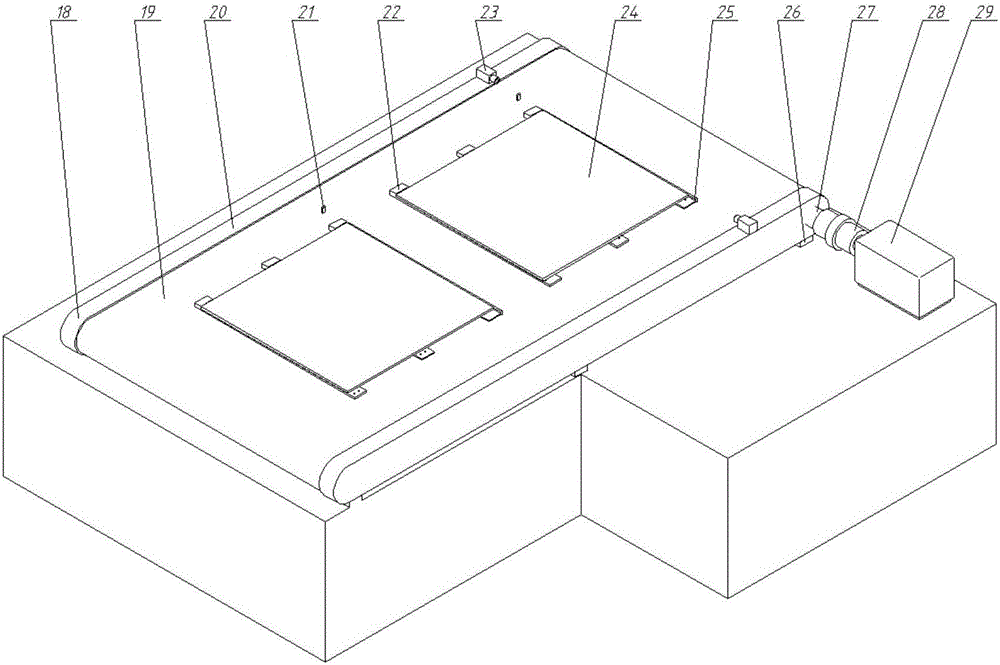

[0043] Such as Figure 1-Figure 7 As shown, a femtosecond laser parallel processing device for scattering dots of a light guide plate includes a light guide plate, a light guide plate transmission positioning device, a light guide plate processing center device, a heat exhaust and dust removal device, a femtosecond laser holographic parallel processing system and a control center. The light guide plate transmission and positioning device, the light guide plate processing center device, the heat removal and dust removal device and the control center are arranged on the frame 2; the light guide plate transmission and positioning device includes a light guide plate transmission mechanism, an adsorption device and a grating positioning sensor 23, The light guide plate transmission mechanism is used to transmit the light guide plate for scattering dot processing, the light guide plate transmission mechanism is driven by a transmission servo motor 29, the upper part of the light guid...

Embodiment 2

[0059] A method for parallel processing of scattering dots of a light guide plate by a femtosecond laser, comprising the following steps:

[0060] Step 1 Place the light guide plate on the adsorption device of the conveyor belt, and the accurate positioning of the light guide plate on the conveyor belt is realized by the adsorption device;

[0061] Step 2. The light guide plate transmission mechanism transports the light guide plate to the position of the grating positioning sensor through the conveyor belt, and the transmission servo motor stops rotating;

[0062] Step 3. The light guide plate processing center device starts to work, and the femtosecond laser holographic parallel processing system splits and focuses the beam of the laser head; The bar feeding device realizes the feeding of the laser head, thereby completing the processing of the scattering dots of the light guide plate;

[0063] Step 4 During the processing, the heat exhaust and dust removal device works at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com