Robot system based on high-tension distributing line electricity testing and ground lead operation

A robot system and high-voltage power distribution technology, applied in the field of robot systems, can solve problems such as high labor intensity, high risk, and low degree of automation, and achieve the effects of maintaining safe operation, improving quality and efficiency, and overcoming low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

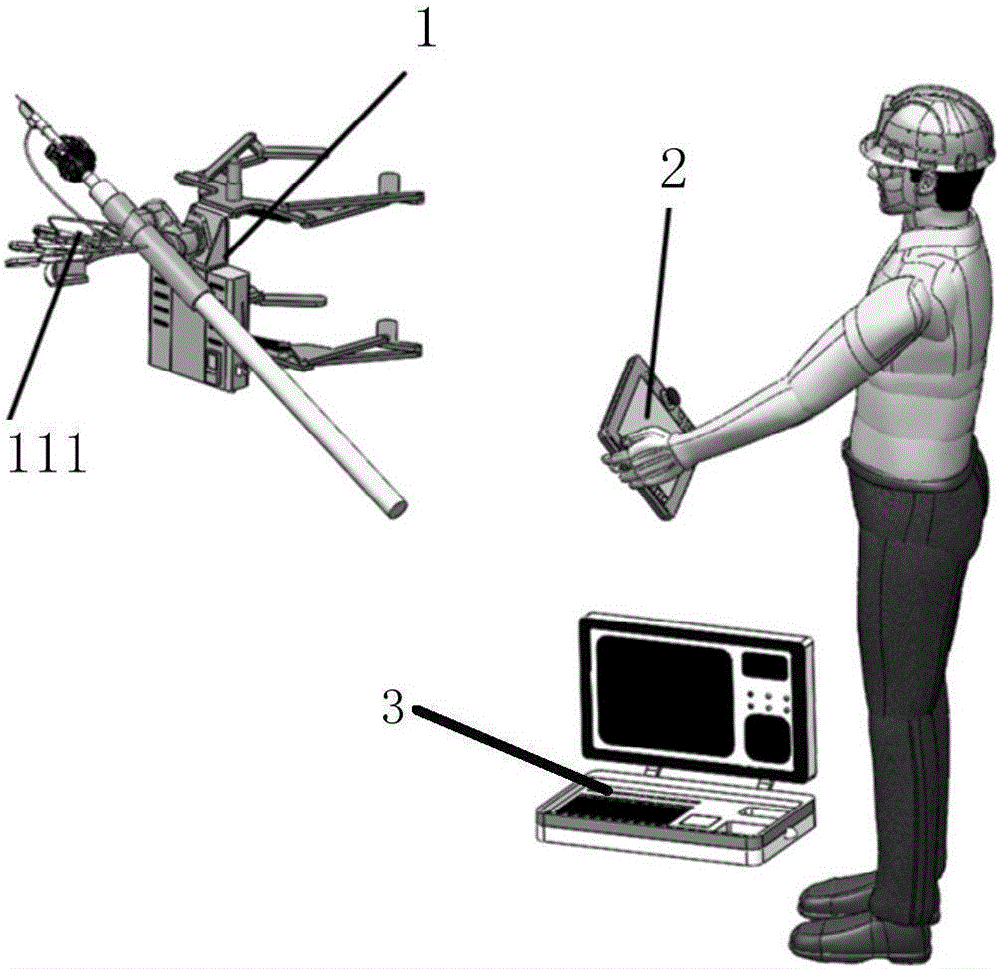

[0036] see figure 1 As shown, it is a schematic diagram of the overall structure of a robot system based on high-voltage power distribution line inspection and grounding wire operation provided by this application. The robot system includes a robot body 1, a handheld control terminal 2, and a ground control terminal 3.

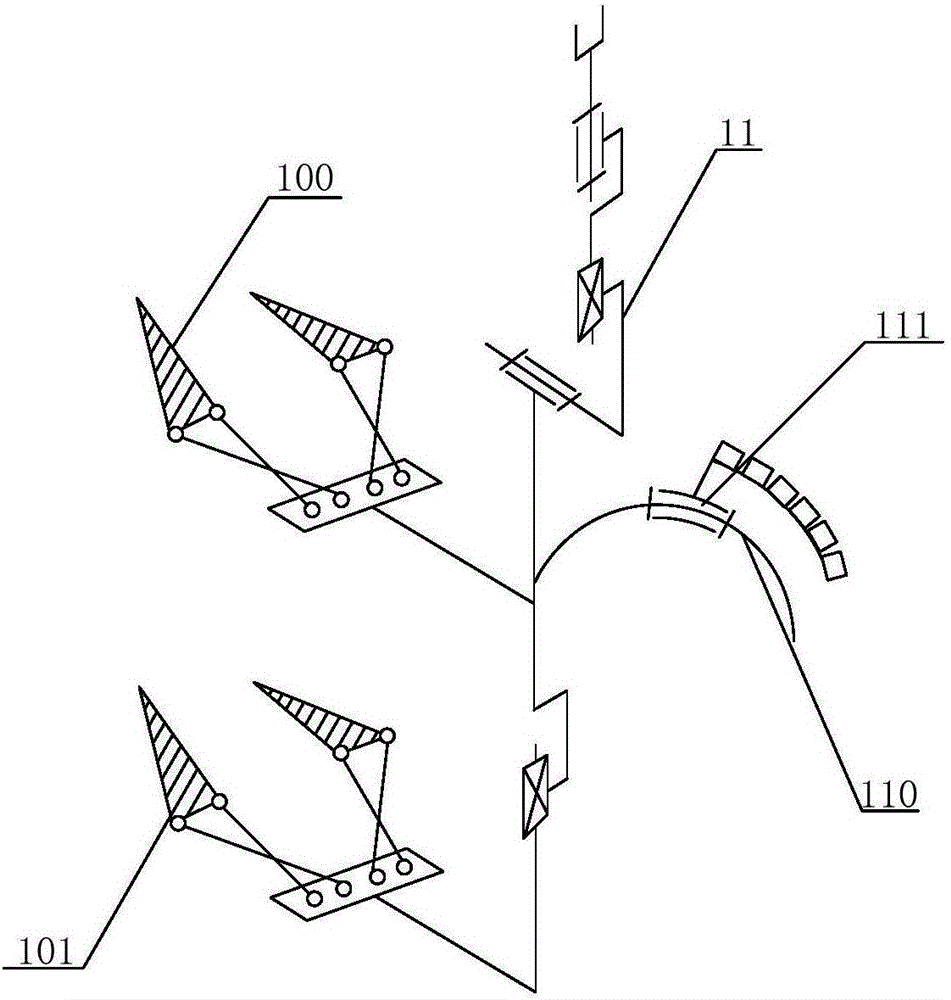

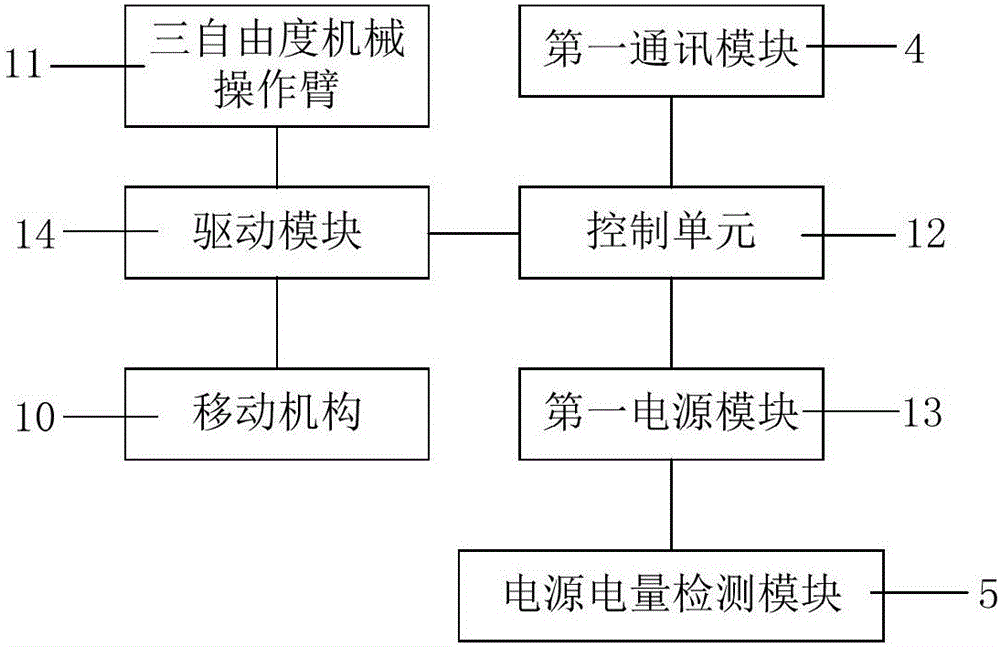

[0037] see figure 2 and image 3 As shown, the robot body 1 includes a connected moving mechanism 10 and a three-degree-of-freedom mechanical operation arm 11. The robot body 1 also includes a control box installed on the robot body 1. The control box body A control unit 12, a first power supply module 13 and a first communication module 4 are installed inside;

[0038] The first power supply module 13 is connected to the control unit 12, the control unit 12 is connected to the drive module 14, and the drive module 14 is respectively connected to the moving mechanism 10 and the three-degree-of-freedom mechanical manipulation arm 11;

[0039] The control un...

Embodiment 2

[0049] On the basis of Embodiment 1, the robot system adopts an embedded control system based on DSP+CPLD, including a control unit 12, a first power supply module 13 and a first communication module 4,

[0050] The control unit 12 selects a motor drive dedicated chip TMS320F2812, which has rich embedded resources and fast data processing speed, and is suitable for robot systems. The motor drive and peripheral input and output control of the robot system, etc., adopt the programmable logic device EPM1270 of ALTERA Company as a coprocessor, which is used to generate part of the PWM pulse and perform QEP quadrature encoding pulse counting work, etc. The CPLD chip and The voltage of the TMS320F2812 chip is matched, and the configuration chip is integrated inside and has a large capacity.

[0051] The first power supply module 13 is powered by a 24V lithium-ion battery, and the output voltage of the rechargeable battery is between 23V and 28V. In order to prevent the power supply...

Embodiment 3

[0059] On the basis of Embodiment 1, the handheld control terminal 2 includes an embedded system board 22, buttons 20 respectively connected to the embedded system board 22, an indicator light 21, a second power supply module 23, and a serial port communication module 24, The serial communication module 24 is also connected with a wireless communication module 25 and a touch screen 26 .

[0060] Further, the handheld control terminal 2 also includes a plurality of interfaces arranged on the embedded system board 22, and the interfaces include SCI interface, JTAG interface and AD interface.

[0061] Further, the control terminal 2 is a remote controller for remotely controlling the robot, which is easy to carry and operate, and is mainly used to realize operations such as forward, backward, and stop of the robot and state monitoring, and three degrees of freedom for the robot arm precise motion control.

[0062] Optionally, the embedded system board 22 uses TMS320F2812 as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com