Thermal-insulation and anti-explosion window membrane with color-changeable patterns and preparation method of thermal-insulation and anti-explosion window membrane

A color-changing and window film technology, applied in chemical instruments and methods, radiation-absorbing coatings, lamination, etc., can solve the problem of single performance of the protective film, and achieve the effect of not being easy to wear and meeting the needs of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further understand the features, technical means, and specific goals and functions of the present invention, and to analyze the advantages and spirit of the present invention, the present invention is further described by the following examples.

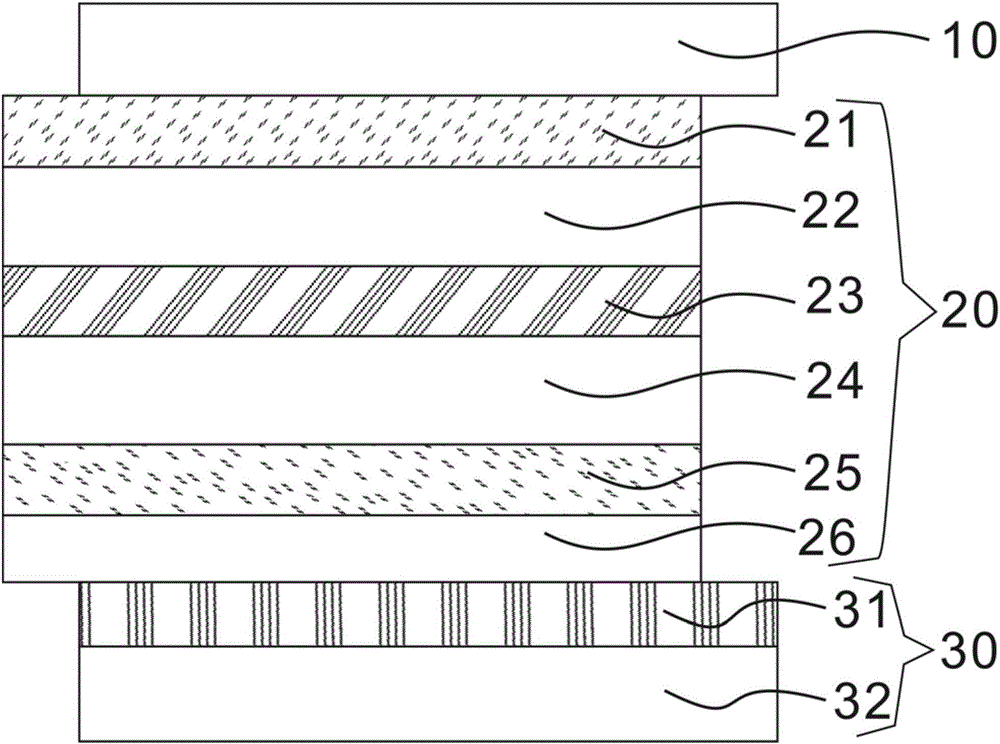

[0060] A heat-insulating and explosion-proof window film with a variable color pattern and a preparation method thereof provided by the present invention include three layers from bottom to top: a protective film layer 30 (ET), a use layer 20, and a peeling layer 10 (release film).

[0061] In some embodiments, the pellicle layer 30 includes a pellicle substrate 32 and a pellicle adhesive layer 31, and the pellicle layer 30 is connected to the hardening protective layer 26 (UV hardening layer).

[0062] The protective film substrate 32 is PET, and its thickness ranges from 25 to 100 μm;

[0063] The protective film adhesive layer 31 is a silicone pressure-sensitive adhesive. The silicone pressure-sensitive adhesive i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com