Method for preparing BiOCuS nanosheets by adopting concentrated alkali hydrothermal method

A nano-sheet and alkaline water technology, applied in the field of materials science, can solve the problems of high raw material requirements, complex process and high energy consumption, and achieve the effects of lowering reaction temperature, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

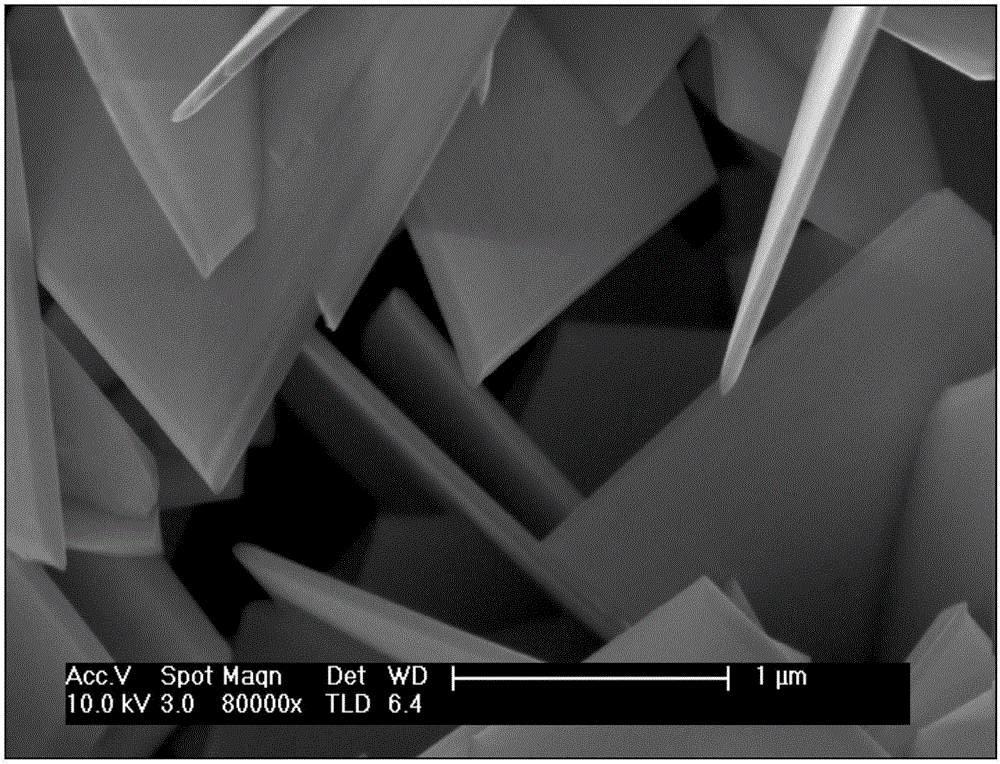

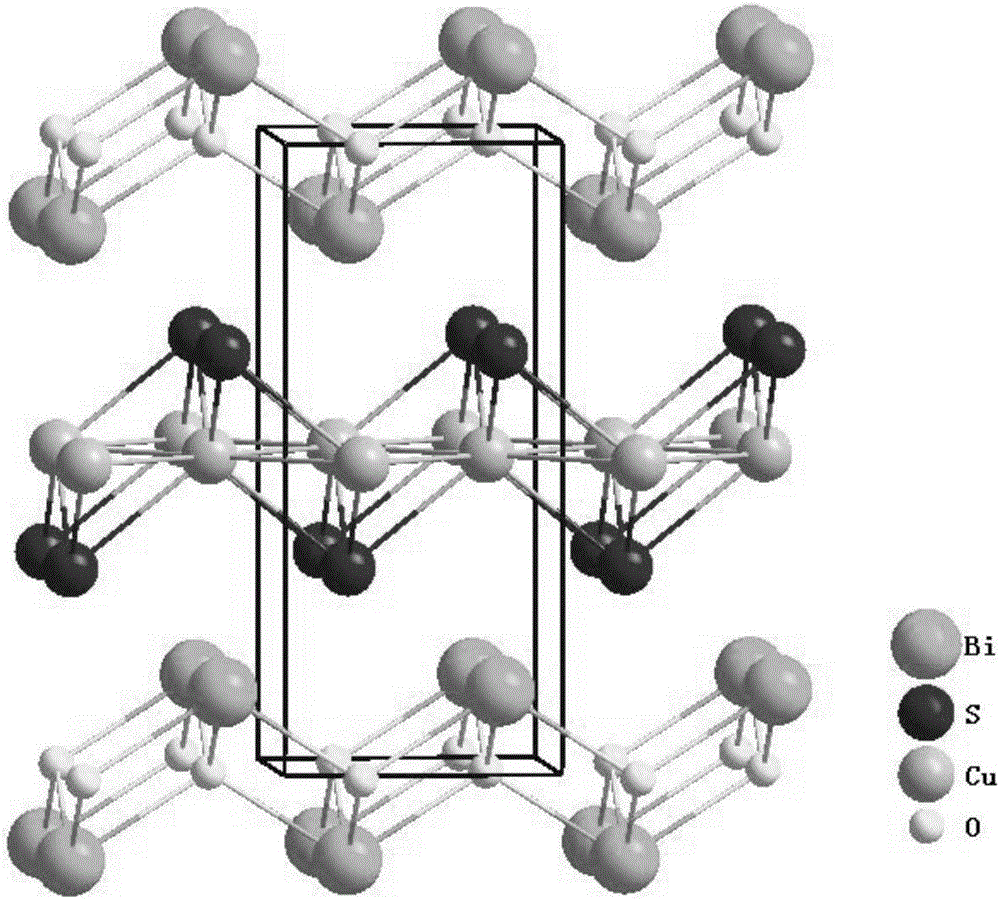

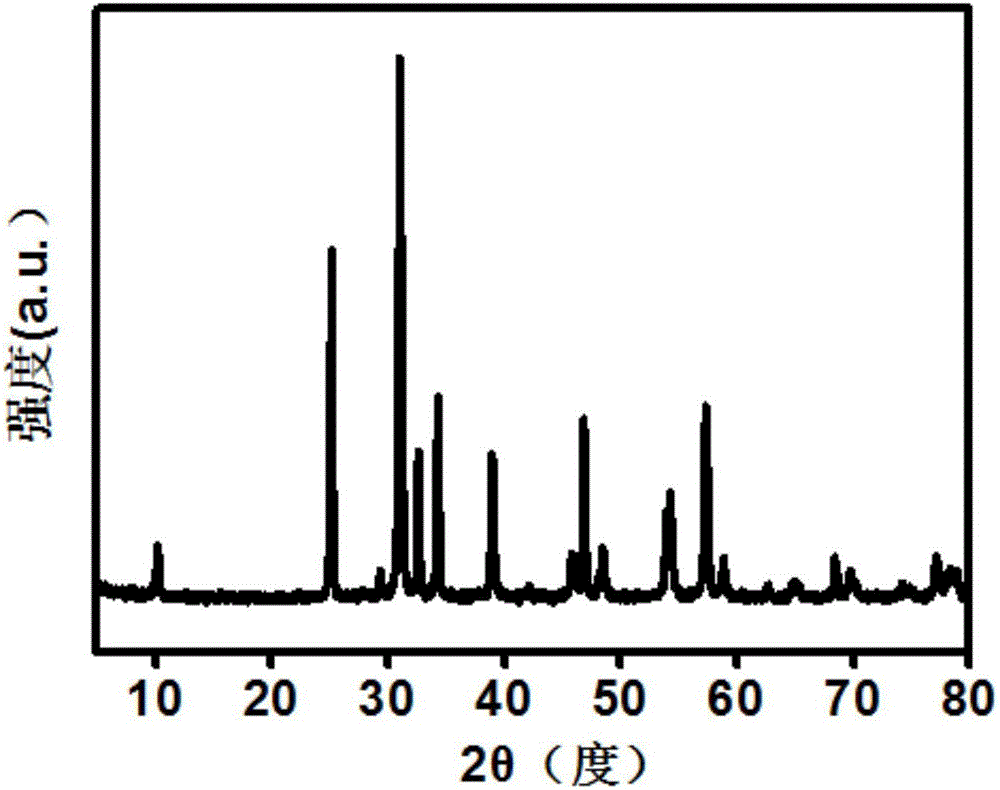

[0021] Firstly, 6 mmol of sulfur powder, 4 mmol of copper chloride, 2 mmol of bismuth nitrate pentahydrate, 5 g of potassium hydroxide, and 10 mL of deionized water were successively added into the reactor, and stirred at room temperature for 30 min until the reaction Then the reactor was sealed and placed in a vacuum oven at 200 °C for 3 days, and finally centrifuged and dried to obtain BiOCuS nanosheets.

Embodiment 2

[0023] First, the reactant precursors 8 mmol sodium sulfide, 6 mmol copper oxide, 4 mmol bismuth acetate, 10 g cesium hydroxide, and 20 mL deionized water were added to the reaction kettle in sequence, and stirred at room temperature for 15 min until the reactants were dissolved. Then seal the reaction kettle and place it in a vacuum oven at 240 °C for 4 days to react, and finally centrifuge and dry to obtain BiOCuS nanosheets.

Embodiment 3

[0025] First, 30 mmol of thiourea, 16 mmol of cuprous chloride, 8 mmol of bismuth oxide, 20 g of sodium hydroxide, and 50 mL of deionized water were successively added to the reaction kettle, and stirred at room temperature for 20 min until the reactants Dissolve, then seal the reaction vessel and place it in a vacuum oven at 200 °C for 5 days, and finally centrifuge and dry to obtain BiOCuS nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com