Irrigation water pretreatment system and farm irrigation system

A pretreatment and irrigation water technology, applied in the field of agricultural irrigation, can solve the problems of inapplicable breeding biogas slurry pretreatment and irrigation water pretreatment system, and achieve the effects of maximizing fertilizer efficiency, saving resources and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

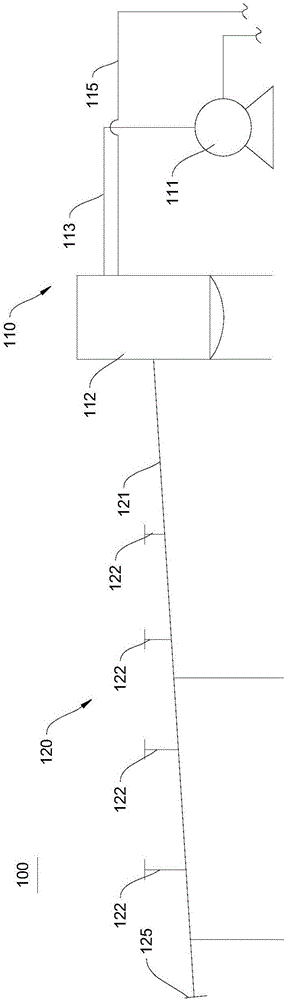

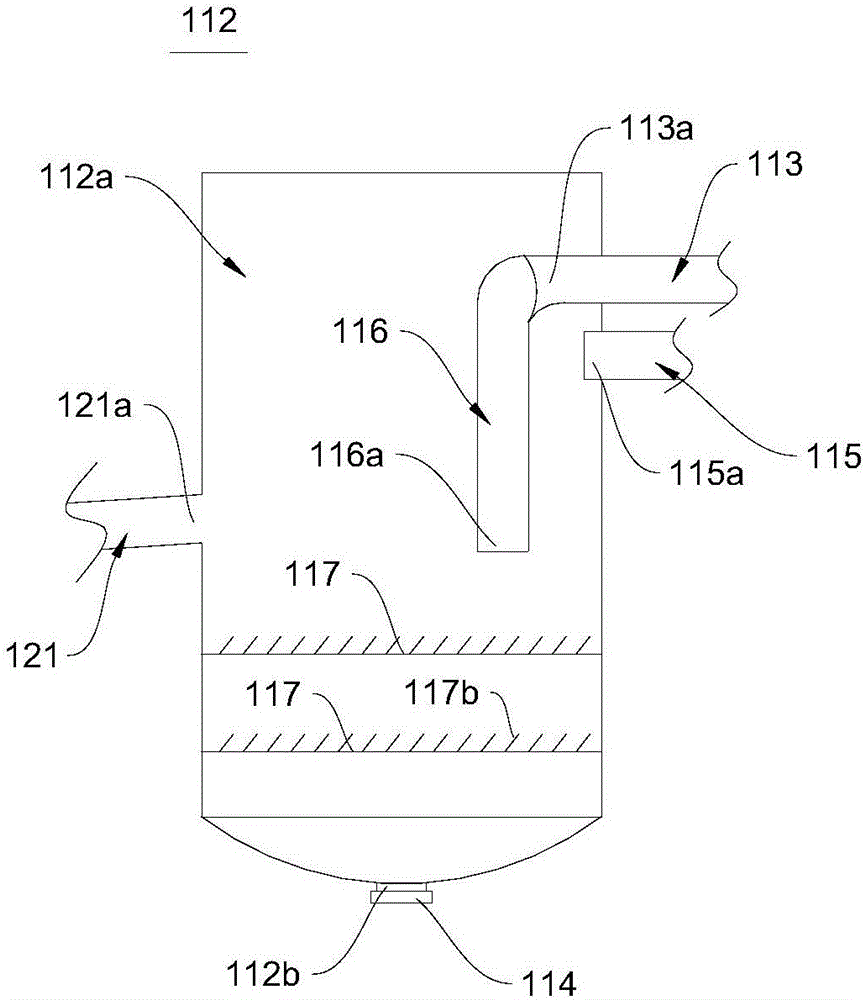

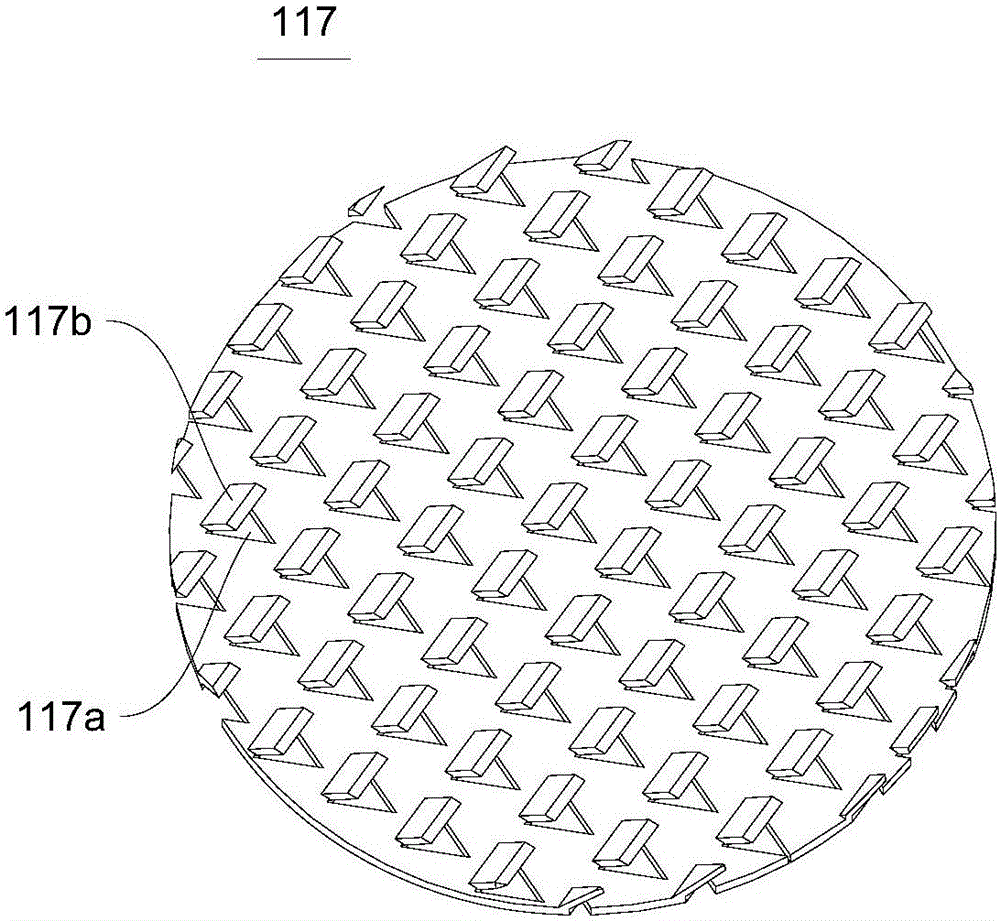

[0031] Please refer to figure 1 and figure 2 , this embodiment provides a lifting water distribution system 100 for water distribution in farmland. The lifting water distribution system 100 includes a lifting water distribution device 110 and a water distribution device 120 . The lifting water distribution device 110 includes a lifting pump 111 and a water distribution device 112. The water distribution device 112 has a water distribution chamber 112a. The outlet of the lifting pump 111 communicates with the water distribution chamber 112a through a water delivery pipe 113. The outlet of the water delivery pipe 113 communicates with the water distribution chamber 112 a, and the lift pump 111 is used to supply water to the water distribution device 112 . The outlet of the water pipe 113 is the first outlet 113a.

[0032] Further, the water distributor 112 is provided with a cleaning port 112b for cleaning the water distribution chamber 112a of the water distributor 112, and...

Embodiment 2

[0057] see Figure 5 , Figure 6 and Figure 7 , the present embodiment provides a lifting water distribution system 200. The difference between the lifting water distribution system 200 and the lifting water distribution system 100 is that the water distributor 112 of the lifting water distribution system 200 has a stirring assembly 220, and the stirring assembly 220 includes a stirring rod 221, stirring impeller 222 and power unit 223. One end of the stirring rod 221 is accommodated in the water distribution chamber 112a of the water distributor 112, the other end of the stirring rod 221 penetrates the side wall of the water distributor 112 and is connected with the power output part of the power unit 223, and the stirring impeller 222 and the stirring rod 221 pass through the bevel gear Mesh connection.

[0058] Further, the axis of the stirring rod 221 coincides with the axis of the water distribution chamber 112a, and the axis of the stirring rod 221 coincides with the...

Embodiment 3

[0077] see Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 , the present embodiment provides a water level control valve 400 , the water level control valve 400 includes a valve body 410 , a regulator 420 , a valve core 430 and a valve core adjusting rod 470 .

[0078] The valve body 410 has a valve cavity 411 , and the regulator 420 includes an adjusting rod 421 and an adjusting sleeve 422 sleeved on the adjusting rod 421 . The adjusting rod 421 and the adjusting sleeve 422 are threadedly connected. The adjusting rod 421 and the adjusting sleeve 422 can rotate relatively. The adjustment sleeve 422 is protrudingly provided with a slider 422a, the slider 422a protrudes from the side wall of the adjustment sleeve 422 toward the side away from the axis of the adjustment sleeve 422, and the extension direction of the slider 422a is in line with the axis of the adjustment sleeve 422 parallel. The inner wall of the valve main body 410 is provided with a sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com