Method for improving immobilization of chloridion in hardened cement paste

A technology of chloride ion and cement slurry, which is applied in the field of building materials, to achieve the effect of improving the fixing capacity of chloride ion, widening the application and alleviating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

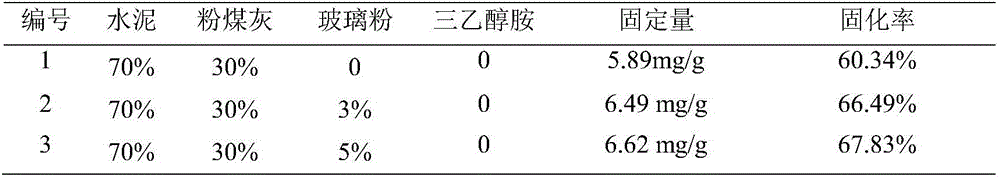

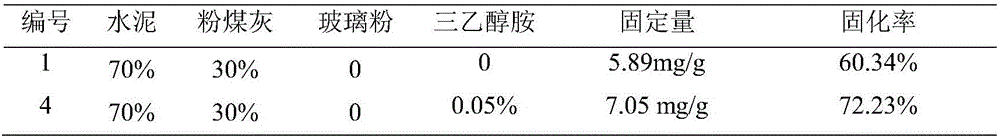

[0024] Table 3 The influence of triethanolamine and glass powder mixture on the fixed amount of chloride ion and curing rate

[0025]

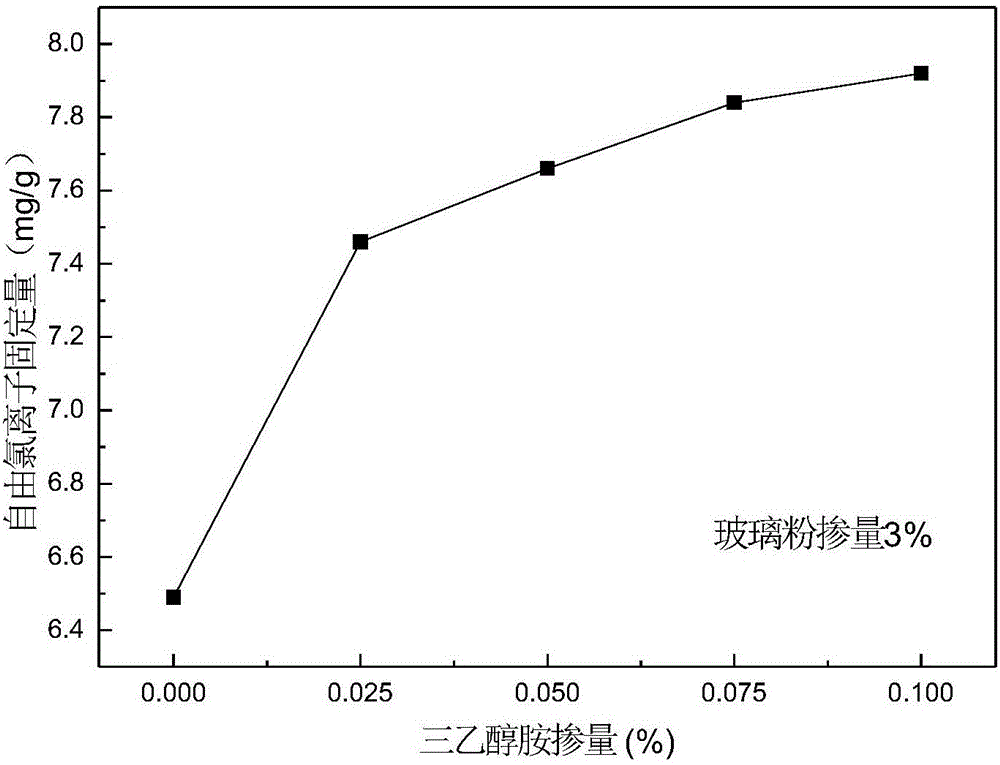

[0026] In order to make the data more intuitive, draw the data in the above table into a line graph as shown in figure 1 .

[0027] From Table 3 and figure 1 It can be seen that when 3% glass powder and 0.025-0.1% triethanolamine are mixed in, the amount of chloride ion fixation is 7.46-7.96mg / g, and the curing rate is 76.43-81.15%. The amount of chloride ion fixation increases with the increase of triethanolamine content. Large, at 0-0.025%, the growth rate is the largest.

[0028] Based on the above Comparative Example 1, Comparative Example 2, and Example 3, it can be seen that in the cement slurry, the addition of 3-5% glass powder and 0.025-0.1% triethanolamine can significantly increase the chloride ion concentration in the hardened cement slurry. the ability to fix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com