Synthetic method of slippery water fracturing degradable diverting agent

A synthesis method and diverting agent technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of unsatisfactory plugging strength of temporary plugging agent, poor flowback performance, high cost of raw materials, etc., and achieve pressure-bearing Strong deformation ability, good flowback performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, a kind of synthetic method of slippery water fracturing degradable diverting agent, comprises the following steps:

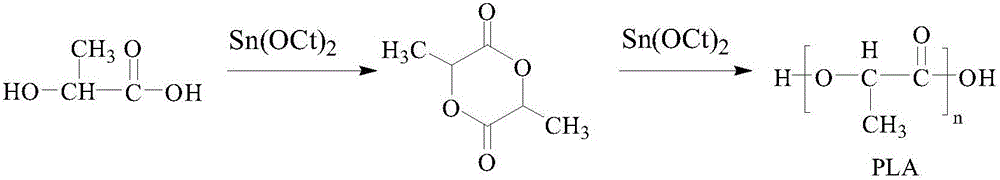

[0017] 1) With lactic acid (LA) as a monomer, stannous octoate (Sn(Oct) 2) As an initiator, control the temperature at 175 ° C, and synthesize polylactic acid (PLA) with carboxyl groups at the end under the protection of nitrogen, in which stannous octoate (Sn(Oct) 2) The amount of addition is 0.5% of the total amount of monomers, the reaction time is 8h, and the molecular weight of polylactic acid (PLA) with carboxyl groups at the end is 40,000 to 60,000.

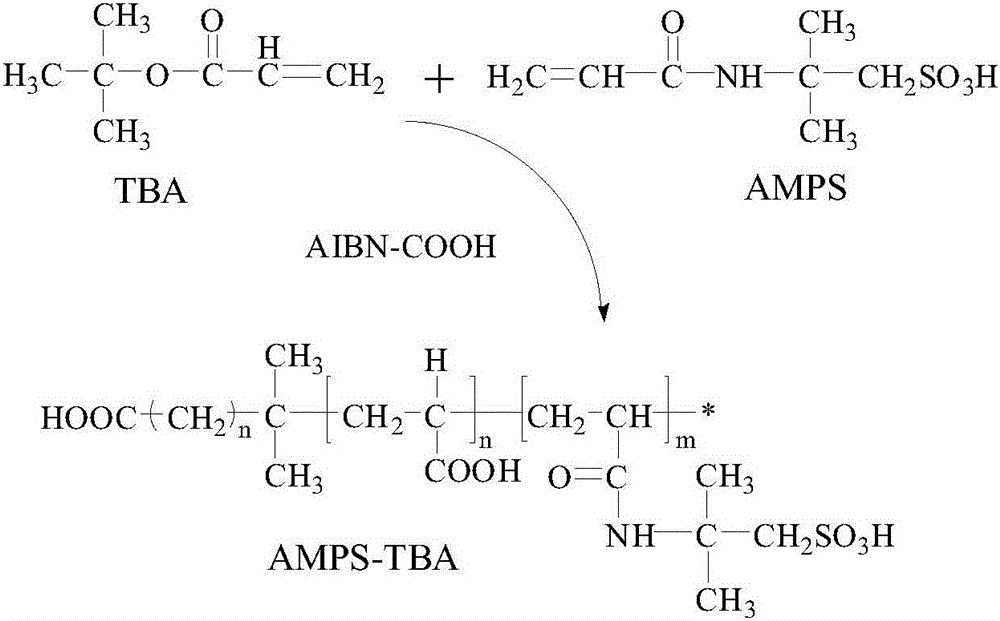

[0018] 2) With tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) as functional monomers, carboxyl azo compound (4,4'-azobis(4-nitrile Valeric acid)) was used as an initiator to synthesize terminal carboxyl-containing oligomers (AMPS-TBA) under the protection of nitrogen, wherein tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) ...

Embodiment 2

[0021] Embodiment 2, a kind of synthetic method of slick water fracturing degradable diverting agent, comprises the following steps:

[0022] 1) With lactic acid (LA) as a monomer, stannous octoate (Sn(Oct) 2) As an initiator, control the temperature at 180 ° C, and synthesize polylactic acid (PLA) with carboxyl groups at the end under the protection of nitrogen, in which stannous octoate (Sn(Oct) 2) The amount of addition is 0.5% of the total amount of monomers, the reaction time is 10h, and the molecular weight of polylactic acid (PLA) with a carboxyl group at the end is 40,000 to 60,000.

[0023] 2) With tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) as functional monomers, carboxyl azo compound (4,4'-azobis(4-nitrile Valeric acid)) was used as an initiator to synthesize terminal carboxyl-containing oligomers (AMPS-TBA) under the protection of nitrogen, wherein tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) T...

Embodiment 3

[0026] Embodiment 3, a kind of synthetic method of slick water fracturing degradable diverting agent, comprises the following steps:

[0027] 1) With lactic acid (LA) as a monomer, stannous octoate (Sn(Oct) 2) As an initiator, control the temperature at 185°C, synthesize polylactic acid (PLA) with a carboxyl group at the end under nitrogen protection, wherein the addition of stannous octoate (Sn(Oct) 2 ) is 0.5% of the total amount of monomers, and the reaction time is 12h, the molecular weight of polylactic acid (PLA) with carboxyl group at the end is 40,000 to 60,000,

[0028] 2) With tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) as functional monomers, carboxyl azo compound (4,4'-azobis(4-nitrile Valeric acid)) was used as an initiator to synthesize terminal carboxyl-containing oligomers (AMPS-TBA) under the protection of nitrogen, wherein tert-butyl acrylate (TBA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) The mass ratio is 1:2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com