Ultralow-odor ultralow-emission PC/ABS alloy and preparation method thereof

A low-odor and ultra-low technology, applied in the field of polymer materials, can solve the problems of reducing odor and emission performance, PC is prone to hydrolysis, and the effect of odor is limited, so as to meet the requirements of odor and VOC, and improve odor and emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

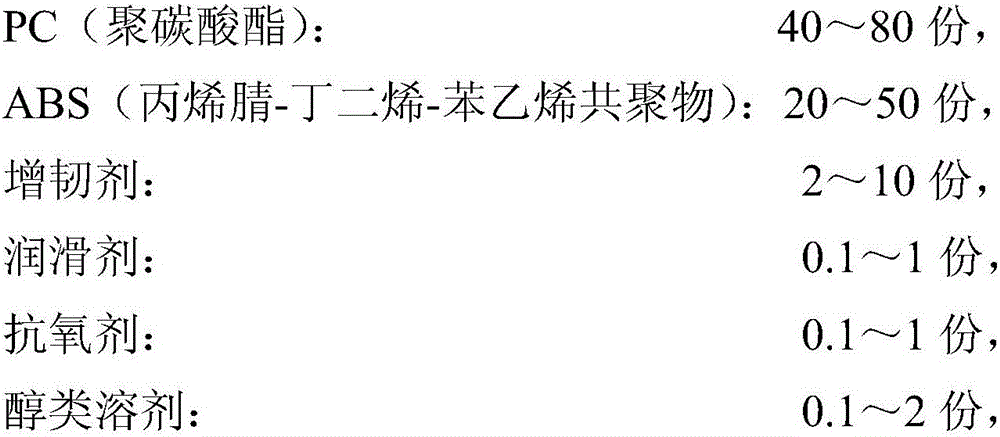

[0049] S1. Raw materials were prepared according to the proportions in parts by weight in Table 1, put into a premixer to mix the raw materials evenly (except ethanol), and heated to 60° C. and then kept for 15 minutes to obtain a premix;

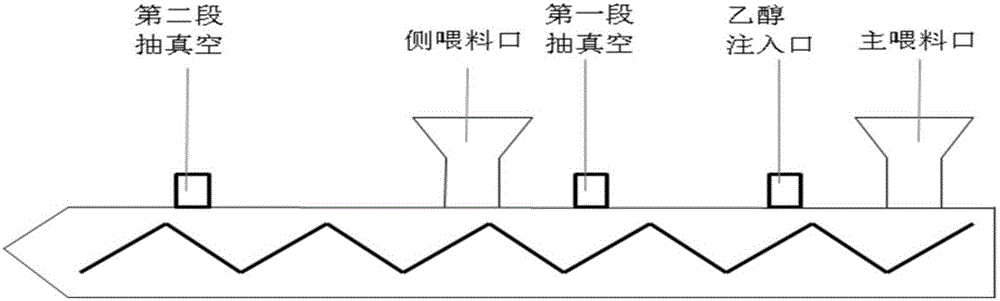

[0050] S2. Add the premixed material obtained in step S1 into the twin-screw extruder, and inject ethanol solvent through the spray device at the first section of the screw, and pelletize to obtain the PC / ABS composite material, wherein the material of the twin-screw extruder The barrel speed is 300rpm, and the barrel temperature is 220-270°C;

[0051] S3. The PC / ABS composite material prepared in step S2 is injected into a finished product.

Embodiment 2

[0053]S1. Raw materials were prepared according to the proportions in parts by weight in Table 1, put into a premixer to mix the raw materials evenly (except ethanol), and heated to 60° C. and then kept for 15 minutes to obtain a premix;

[0054] S2. Add the premixed material obtained in step S1 into the twin-screw extruder, and inject ethanol solvent through the spray device at the first section of the screw, and pelletize to obtain the PC / ABS composite material, wherein the material of the twin-screw extruder The barrel speed is 300rpm, and the barrel temperature is 220-270°C;

[0055] S3. The PC / ABS composite material prepared in step S2 is injected into a finished product.

Embodiment 3

[0057] S1. Raw materials were prepared according to the proportions in parts by weight in Table 1, put into a premixer to mix the raw materials evenly (except ethanol), and heated to 60° C. and then kept for 15 minutes to obtain a premix;

[0058] S2. Add the premixed material obtained in step S1 into the twin-screw extruder, and inject ethanol solvent through the spray device at the first section of the screw, and pelletize to obtain the PC / ABS composite material, wherein the material of the twin-screw extruder The barrel speed is 300rpm, and the barrel temperature is 220-270°C;

[0059] S3. The PC / ABS composite material prepared in step S2 is injected into a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com