Multi-component sealant and preparation method thereof

A kind of beautifying agent and multi-component technology, applied in the field of sealants, can solve the problems of not being resistant to water scrubbing, easy yellowing after a long time, and short duration of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

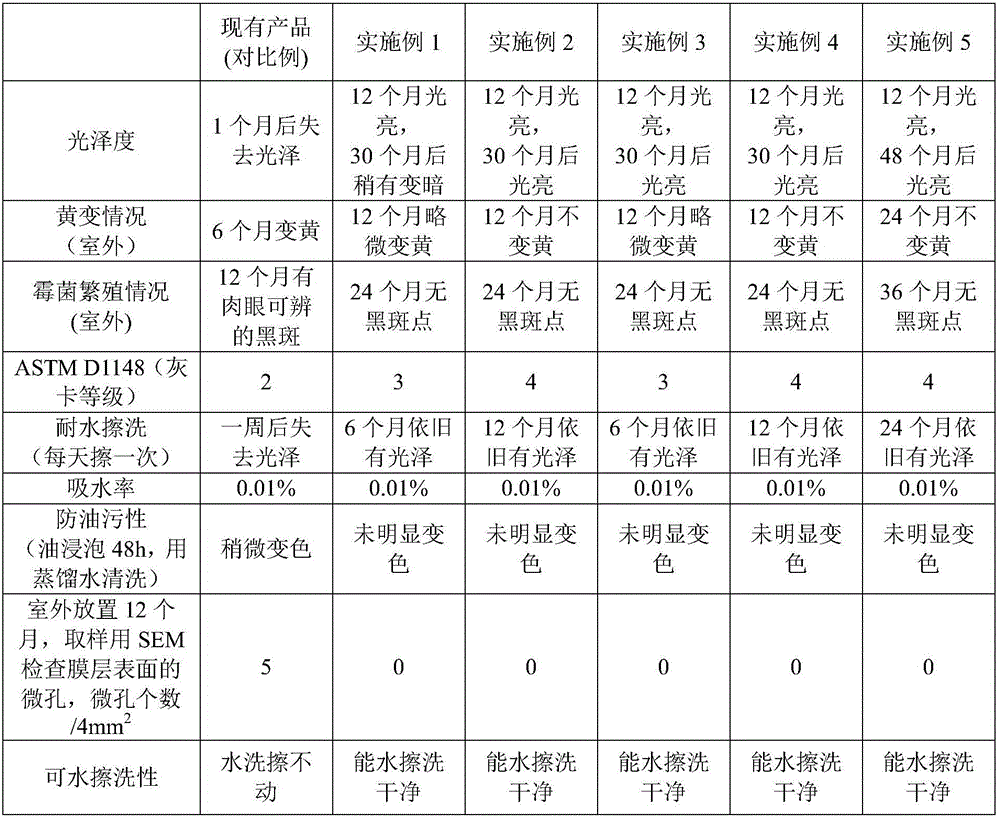

Examples

preparation example 1

[0089] Preparation of modified curing agent I (a): 30 parts by weight of 1,3-diglycidyl ester-5,5-dimethyl polymer was added dropwise to 23 parts by weight of isophoronediamine ( In the molecular weight of 170), the reaction temperature is controlled at 50°C, and the reaction is performed for 2 hours to obtain the modified curing agent I(a).

preparation example 2

[0091] Preparation of modified curing agent I (b): Add 30 parts by weight of 1,3-diglycidyl ester-5,5-dimethyl polymer dropwise to 23 parts by weight of diaminomethylcyclohexane within 1.5h , control the reaction temperature to 50°C, and react for 2 hours to obtain the modified curing agent I(b).

preparation example 3

[0093] Preparation of modified curing agent I (c): 13 parts by weight of isophorone diamine and 10 parts by weight of diaminomethylcyclohexane are mixed uniformly to form a mixture, and 30 parts by weight of 1,3-bis Glycidyl ester-5,5-dimethyl polymer was added dropwise to the mixture within 1.5 hours, the reaction temperature was controlled at 50° C., and the reaction was carried out for 2 hours to obtain the modified curing agent I(c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com