Method for preparing fermented tobacco dendranthema indicum essential oil

A Shennong fragrant chrysanthemum, fermentation type technology, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of low efficiency and low oil rate, and achieve the effect of simple process, delicate smoke, and increased oral aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

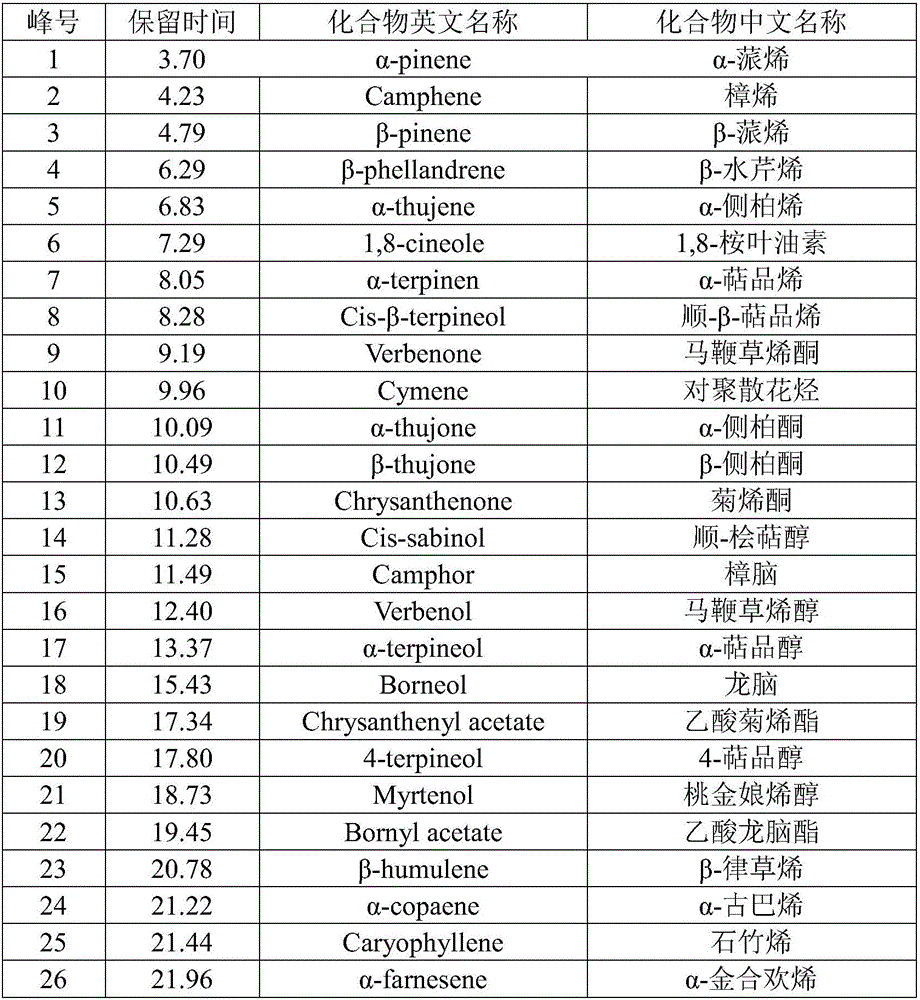

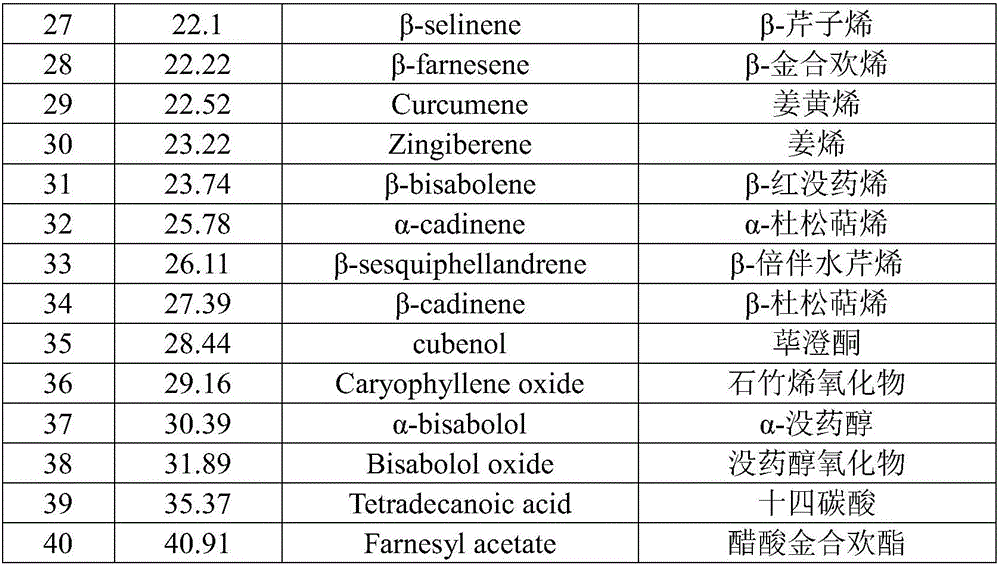

Image

Examples

Embodiment 1

[0027] The preparation method of fermented Shennong fragrant chrysanthemum essential oil 1 for tobacco comprises the following steps:

[0028] 1) Weigh Shennong chrysanthemum and crush Shennong chrysanthemum into 80-mesh Shennong chrysanthemum powder, mix Shennong chrysanthemum powder: glucose: water in a weight ratio of 6:2:92 to obtain a mixed solution;

[0029] 2) uniformly mixing Bacillus subtilis, saccharomyces, Aspergillus niger and Trichoderma reesei in a weight ratio of 1:1:2:2 to obtain a fermentation composite bacterium;

[0030] 3) According to the inoculum size of 0.3, inoculate the fermentation compound bacteria into the mixed solution for fermentation. Under the conditions of pH value of 2.5, stirring speed of 250r / min, and ventilation rate of 1VVM, first ferment at 20°C for 5 days, and then in Fermentation at 8°C for 25 days to obtain a fermentation broth;

[0031] 4) Put the fermented liquid obtained in step 3) into a bottle, extract it with a volatile oil ext...

Embodiment 2

[0033] The preparation method of the fermented Shennong fragrant chrysanthemum essential oil 2 for tobacco comprises the following steps:

[0034] 1) Weighing Shennong chrysanthemum and crushing Shennong chrysanthemum into 100-mesh Shennong chrysanthemum powder, mixing Shennong chrysanthemum powder: glucose: water in a weight ratio of 8:2.5:89.5 to obtain a mixed solution;

[0035] 2) uniformly mixing Bacillus subtilis, saccharomyces, Aspergillus niger and Trichoderma reesei in a weight ratio of 1:2:2:2 to obtain a fermentation composite bacterium;

[0036] 3) According to the inoculum size of 0.05, inoculate the fermentation composite bacteria into the mixed solution for fermentation. Under the conditions of pH value of 3, stirring speed of 200r / min, and ventilation rate of 2VVM, first ferment at 20°C for 5 days, and then in Fermentation at 8°C for 25 days to obtain a fermentation broth;

[0037] 4) Put the fermented liquid obtained in step 3) into a bottle, extract it with ...

Embodiment 3

[0039] The preparation method of the fermented Shennong fragrant chrysanthemum essential oil 3 for tobacco comprises the following steps:

[0040] 1) Weighing Shennong Xiangju and crushing Shennong Xiangju into 120 mesh Shennong Xiangju coarse powder, mixing Shennong Xiangju coarse powder: glucose: water in a weight ratio of 9:3:88 to obtain a mixed solution;

[0041] 2) uniformly mixing Bacillus subtilis, Aspergillus niger and Trichoderma reesei in a weight ratio of 3:2:3 to obtain a fermentation composite bacterium;

[0042] 3) According to the inoculum size of 0.1, inoculate the fermentation compound bacteria into the mixed liquid for fermentation. Under the conditions of pH value of 4, stirring speed of 180r / min, and ventilation volume of 3VVM, first ferment at 20°C for 7 days, and then in Fermentation at 10°C for 22 days to obtain a fermentation broth;

[0043] 4) Put the fermented liquid obtained in step 3) into a bottle, extract it with a volatile oil extractor, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com