Coal powder additive for smelting of vanadium titano-magnetite and application of coal powder additive

A technology of vanadium-titanium magnetite and additives, applied in the field of metallurgical materials, can solve the problems of limited improvement effect, achieve the effects of reducing the coke ratio, improving the separation effect of slag and iron, and reducing the iron loss of blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned pulverized coal additive for smelting vanadium-titanium magnetite comprises the following steps:

[0028] a. Take fluorspar, crush it, and grind it until the particle size of less than 0.074 accounts for more than 30%, so as to obtain fluorspar powder;

[0029] b. Mix the ground fluorite powder and dedusting ash according to 30-70wt% fluorite powder and 30-70wt% dedusting ash; wherein, the sum of the weight percentages of fluorite powder and dedusting ash is 100%.

[0030] The invention also provides an application method of the pulverized coal additive in the smelting of vanadium-titanium magnetite.

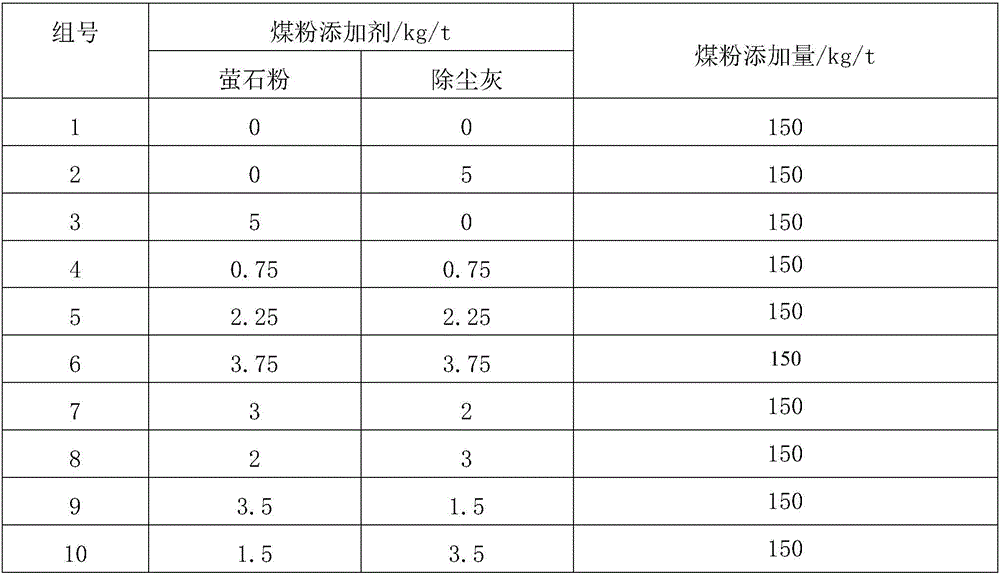

[0031] The application of the above-mentioned pulverized coal additive in the smelting of vanadium-titanium magnetite is specifically: according to the following weight ratio, the pulverized coal additive: pulverized coal=1.5~7.5:150 is mixed and injected; the amount of the pulverized coal additive should not be too much , be...

Embodiment 1

[0037] TiO in blast furnace slag of vanadium-titanium magnetite smelted by Panzhihua Iron and Steel Group Co., Ltd. 2 The content reaches 20-24%. Therefore, the smelting of vanadium-titanium magnetite is improved by injecting mixed additives of fluorite and dedusting ash into the furnace hearth through the tuyere branch pipe, and the different additions are studied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com