Method for preparing composite type iron ore pellet adhesive by utilizing landfill leachate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

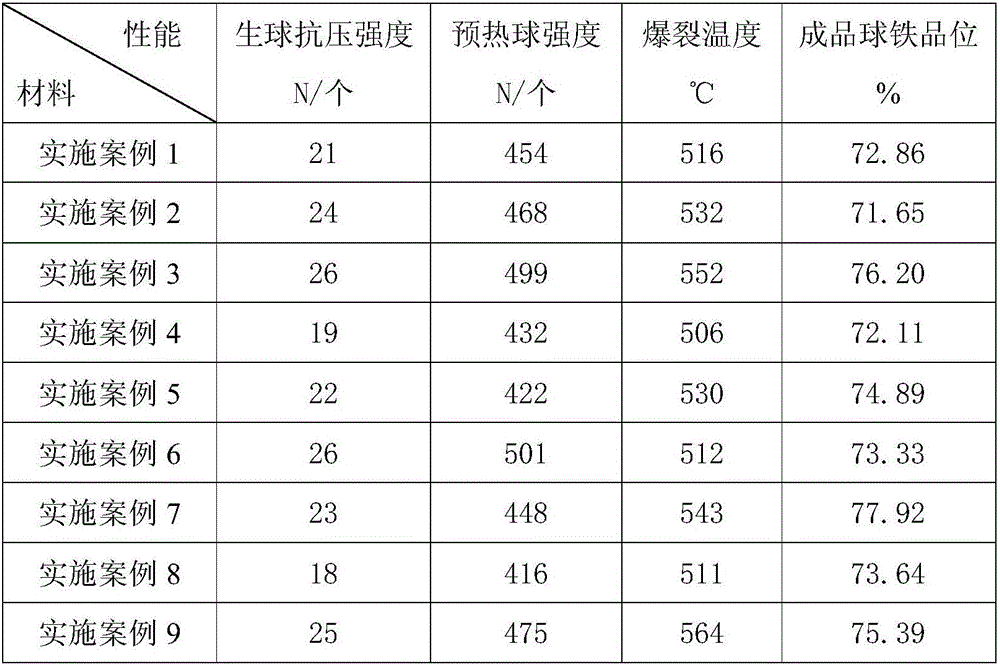

Image

Examples

Embodiment 1

[0021] A kind of method utilizing landfill leachate to prepare composite iron ore pellet binder:

[0022] 100Kg of landfill leachate concentrate with a solid content of 30% and 6Kg of a sodium hydroxide solution with a concentration of 3mol / L were mixed and evenly mixed, and stirred and reacted in a water bath at 80°C for 0.5h, and then the solution was cooled. The modified landfill leachate can be prepared. Mix 40 parts of the modified landfill leachate with 25 parts of cement and 6 parts of quicklime evenly, then add it to the spray drying equipment, and spray dry it at 160°C. Composite iron ore pellet binder can be prepared.

[0023] The composite iron ore pellet binder prepared in this example was added to the iron concentrate by 2% of the mass of the iron ore concentrate to prepare iron ore pellets.

Embodiment 2

[0025] A kind of method utilizing landfill leachate to prepare composite iron ore pellet binder:

[0026] Mix 100Kg of landfill leachate concentrate with a solid content of 35% and 10Kg of a sodium hydroxide solution with a concentration of 3mol / L, and stir and react for 1 hour in a water bath at 85°C, then cool the solution to obtain Modified landfill leachate can be prepared. Mix 40 parts of modified landfill leachate with 25 parts of cement and 6 parts of quicklime evenly, then add it to the spray drying equipment, and spray dry it at 180°C. A composite iron ore pellet binder is prepared.

[0027] The composite iron ore pellet binder prepared in this example was added to the iron concentrate by 2% of the mass of the iron ore concentrate to prepare iron ore pellets.

Embodiment 3

[0029] A kind of method utilizing landfill leachate to prepare composite iron ore pellet binder:

[0030] 100Kg of landfill leachate concentrate with a solid content of 40% was mixed with 6Kg of a sodium hydroxide solution with a concentration of 3mol / L, and stirred and reacted in a water bath at 90°C for 1.5h, and then the solution was cooled. The modified landfill leachate can be prepared. Mix 50 parts of the modified landfill leachate with 30 parts of cement and 12 parts of quicklime evenly, then add it to the spray drying equipment, and spray dry it at 200°C. Composite iron ore pellet binder can be prepared.

[0031] The composite iron ore pellet binder prepared in this example was added to the iron concentrate by 2% of the mass of the iron ore concentrate to prepare iron ore pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com