A kind of high-hardness graphite steel section steel roll and preparation method thereof

A graphite steel, high hardness technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of rapid wear and affect the surface quality of the rolling output section steel, reduce wear, fine structure, and improve rolling output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

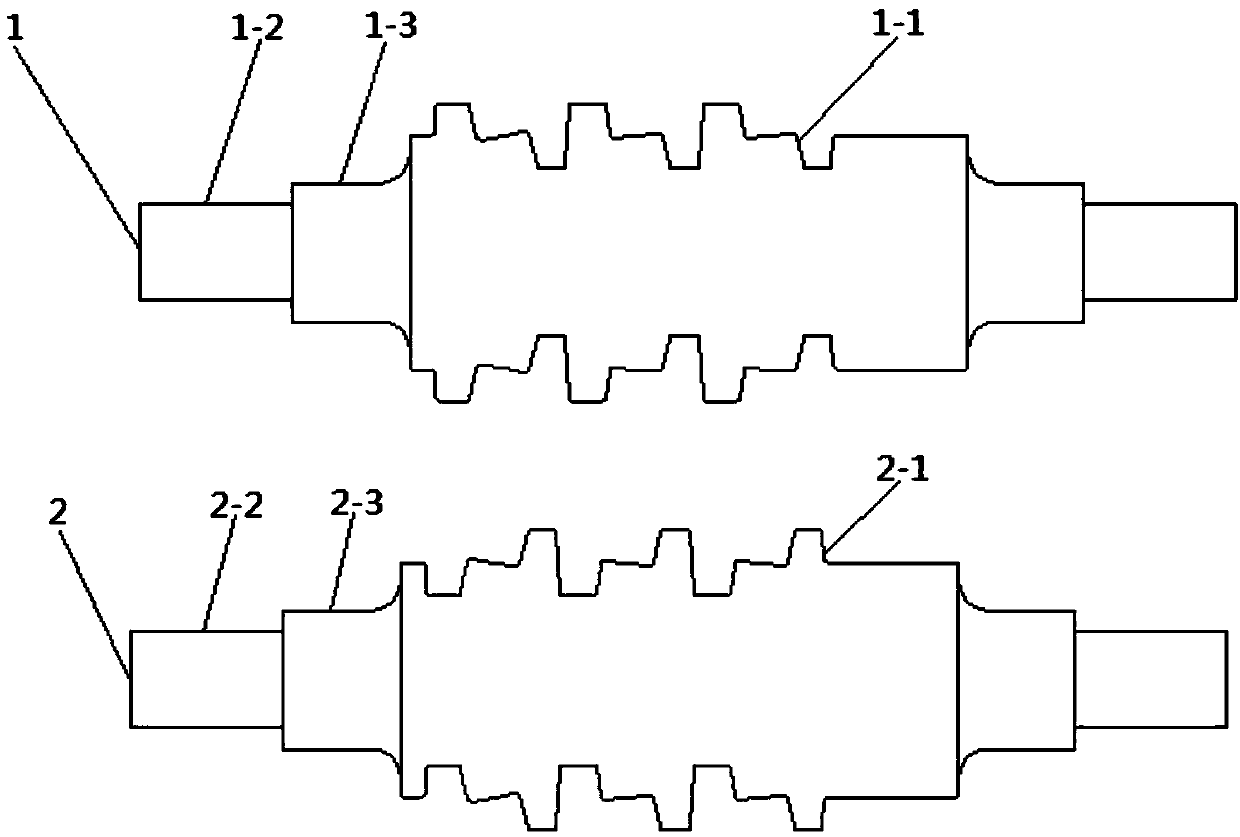

[0028] [Example 1] The structure of the high-hardness graphite steel shaped steel roll of the present embodiment is as follows figure 1 Shown: the assembly of a kind of high-hardness graphite steel section steel roll of the present embodiment, it is characterized in that: comprise the high hardness graphite steel section steel roll of two matrix metallographic structures: graphite+fine-grained carbide+bainite , one of which is used as the main shaft 1, and the other is used as the auxiliary shaft 2, and the two are meshed with each other; the main shaft includes the roll body 1-1 located in the middle, the roll neck 1-2 located at both ends of the roll body 1-1, and the bearing stop roll neck 1-3; the auxiliary shaft includes a roll body 2-1 located in the middle, a roll neck 2-2 located at both ends of the roll body 2-1, and a bearing blocking roll neck 2-3.

[0029] The main shaft 1 roll body 1-1 of the assembly of the roll includes 3 grooves surrounding the roll body 1-1, a...

Embodiment 2

[0039] [Example 2] The chemical composition of the high-hardness graphite steel section steel roll is: C: 2.05%; Si: 1.45%; Mn: 1.10%; Cr: 1.70%; Ni: 1.95%; Mo: 0.65%; P : 0.010%; S: 0.015%; the balance is Fe.

[0040] The design value of the surface hardness of the high-hardness graphite steel-shaped steel roll body is 60-70HSC, and the measured value of the physical product is 63.2HSD; the design value of the tensile strength of the high-hardness graphite steel-shaped steel roll is ≥480MPa, and the measured value of the physical product is 503MPa .

[0041] Step 3. Hot unpacking heat treatment: when the roll reaches 650°C, heat unpack for special heat treatment, heat it at Acm+70°C for 24 hours, take it out of the furnace for water mist spray quenching, and temper it when it reaches 510°C, and the roll is qualified after testing finished product.

[0042] In the third step, when the roll is heated to 570°C, wrap the roll with 45mm thick mineral wool from the R of the two end...

Embodiment 3

[0043] [Example 3] The chemical composition of the high-hardness graphite steel section steel roll is: C: 2.10%; Si: 1.55%; Mn: 1.20%; Cr: 2.15%; Ni: 2.30%; Mo: 0.55%; P : 0.021%; S: 0.012%; the balance is Fe.

[0044] The design value of the surface hardness of the high-hardness graphite steel-shaped steel roll body is 60-70HSC, and the measured value of the physical product is 66.7HSD; the design value of the tensile strength of the high-hardness graphite steel-shaped steel roll is ≥ 480MPa, and the measured value of the physical product is 526MPa .

[0045] Step 3. Hot unpacking heat treatment: when the roll reaches 580°C, it is unpacked for special heat treatment, and it is kept at Acm+80°C for 24 hours, and then it is sprayed and quenched with water mist, and tempered at 580°C, and the roll is tested and qualified finished product.

[0046] In the third step, when the roll is heated to 565°C, wrap the roll with 50mm thick mineral wool from the R at both ends of the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com