Paper treatment agent for blue high-temperature-resistant and high-humidity masking paper and application method thereof

A technology for paper treatment and textured paper, applied in the direction of anti-aging agent addition, physical treatment of paper, fiber raw material treatment, etc., can solve the problems of textured paper performance and color instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

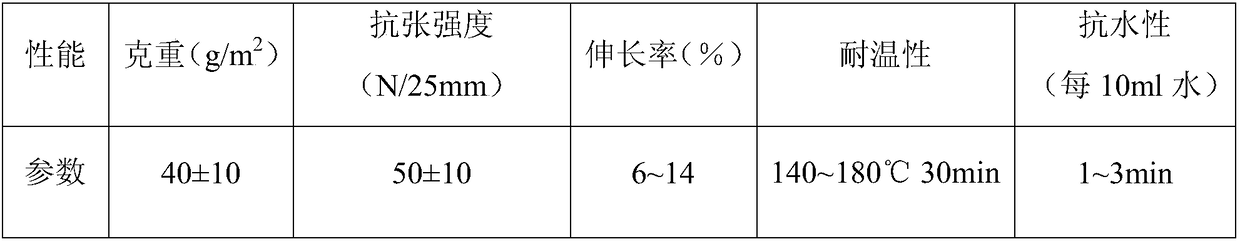

Image

Examples

Embodiment 1

[0037] The paper treatment agent for blue high-temperature-resistant and high-humidity textured paper is composed of the following raw materials in percentage by weight:

[0038] Anatase Titanium Dioxide 45%;

[0039] Rutile titanium dioxide 35%;

[0040] Cetyltrimethylammonium Chloride 5%;

[0041] Anti-aging agent 3%;

[0042] Cobalt Blue 12%.

[0043] The application method of the paper treatment agent for the blue high-temperature-resistant and high-humidity masking paper comprises the following steps:

[0044] (1) Use absolute ethanol as a solvent, first mix and stir the raw materials of the paper treatment agent, and then grind to 6 microns with a three-roll mill;

[0045] (2) After dissolving the paper treatment agent ground in step (1) with acrylic emulsion, impregnating the masking base paper;

[0046] (3) drying the masking base paper impregnated in step (2) in an oven to obtain a finished product.

Embodiment 2

[0048] The paper treatment agent for blue high-temperature-resistant and high-humidity textured paper is composed of the following raw materials in percentage by weight:

[0049] Anatase titanium dioxide 52%;

[0050] Rutile titanium dioxide 28%;

[0051] Cetyltrimethylammonium Chloride 6%;

[0052] Anti-aging agent 4%;

[0053] Cobalt Blue 10%.

[0054] The application method of the paper treatment agent for the blue high-temperature-resistant and high-humidity masking paper comprises the following steps:

[0055] (1) Use absolute ethanol as a solvent, first mix and stir the raw materials of the paper treatment agent, and then grind to ≤6 microns with a three-roll mill;

[0056] (2) After dissolving the paper treatment agent ground in step (1) with nitrile latex, dipping the base paper for masking paper; (3) drying the base paper for masking paper after dipping in step (2) in an oven, Obtain the processed finished product.

Embodiment 3

[0058] The paper treatment agent for blue high-temperature-resistant and high-humidity textured paper is composed of the following raw materials in percentage by weight:

[0059] Anatase titanium dioxide 60%;

[0060] Rutile titanium dioxide 20%;

[0061] Lauryl Dimethyl Benzyl Ammonium Chloride 5%;

[0062] Anti-aging agent 3%;

[0063] Cobalt Blue 12%.

[0064] The application method of the paper treatment agent for the blue high-temperature-resistant and high-humidity masking paper comprises the following steps:

[0065] (1) Use absolute ethanol as a solvent, first mix and stir the raw materials of the paper treatment agent, and then grind to 6 microns with a three-roll mill;

[0066] (2) After dissolving the paper treatment agent ground in step (1) with neoprene latex, impregnate the masking paper base paper;

[0067] (3) drying the masking base paper impregnated in step (2) in an oven to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com