Degradable drag reducer for fracturing and preparation method thereof

A drag reducing agent and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy shearing and broken chains, loss of drag reducing performance, high molecular polymers that are not easy to degrade, and poor shear resistance and other problems, to achieve the effects of avoiding formation pollution, environmental protection and easy availability of raw materials, and good resistance reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

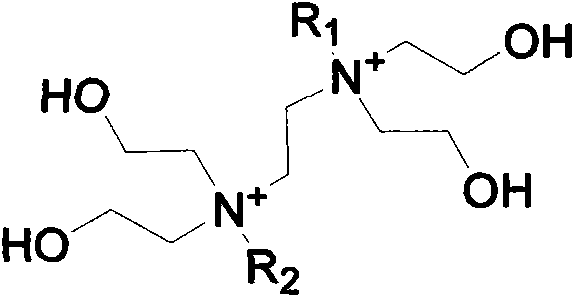

[0026] The present invention is made from the following raw materials in parts by weight: 2% water-soluble polymer, 10% surfactant, 8% organic solvent, 0.1% aldehydes and 79.9% water; the water-soluble polymer is polyacrylamide, The organic solvent is methanol; the aldehyde is formaldehyde; the surfactant is a gemini quaternary ammonium salt type surfactant, and its structure is as follows:

[0027]

[0028] Among them, the synthesis reaction equation is:

[0029] RN(CH 2 CH 2 OH) 2 +BrCH 2 CH 2 Br→(CH 2 CH 2 OH) 2 R 1 N + CH 2 CH 2 N + R 2 (CH 2 CH 2 OH) 2

[0030] In the reaction formula, R is coconut oil base, representing a mixture of C8~C22 alkyl groups, R 1 And R 2 It is C8~C22 long-chain alkyl component, when R 1 And R 2 When the carbon number is the same, a symmetric gemini quaternary ammonium salt surfactant is generated, when R 1 And R 2 When the number of carbons is not the same, asymmetric gemini quaternary ammonium salt surfactants are formed. In the synthesis reaction, ...

Embodiment 2

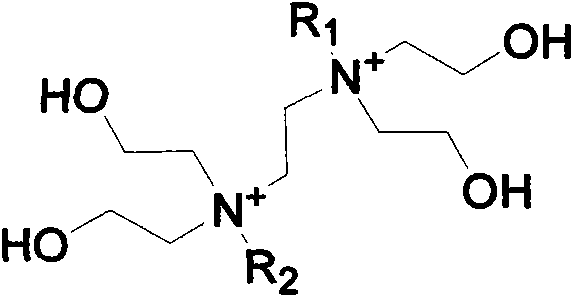

[0037] The present invention is made from the following raw materials in parts by weight: 3.5% water-soluble polymer, 12.5% surfactant, 9% organic solvent, 0.1% aldehydes and 74.9% water; the water-soluble polymer is polyvinyl alcohol, The organic solvent is ethanol; the aldehyde is glyoxal; the surfactant is a gemini quaternary ammonium salt type surfactant, and its structure is as follows:

[0038]

[0039] Among them, the synthesis reaction equation is:

[0040] RN(CH 2 CH 2 OH) 2 +BrCH 2 CH 2 Br→(CH 2 CH 2 OH) 2 R 1 N + CH 2 CH 2 N + R 2 (CH 2 CH 2 OH) 2

[0041] In the reaction formula, R is coconut oil base, representing a mixture of C8~C22 alkyl groups, R 1 And R 2 It is C8~C22 long-chain alkyl component, when R 1 And R 2 When the carbon number is the same, a symmetric gemini quaternary ammonium salt surfactant is generated, when R 1 And R 2 When the number of carbons is not the same, asymmetric gemini quaternary ammonium salt surfactants are formed. In the synthesis reactio...

Embodiment 3

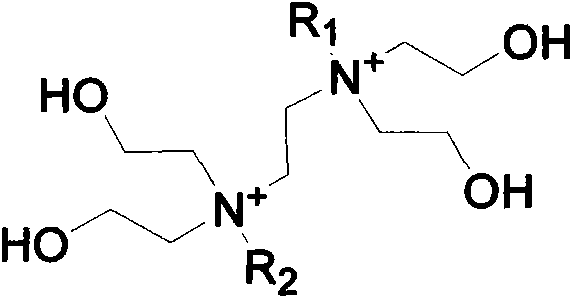

[0049] The present invention is made from the following raw materials in parts by weight: water-soluble polymer 5%, surfactant 15%, organic solvent 10%, aldehyde 0.1% and water 69.9%; the water-soluble polymer is polyacrylamide and The ratio of polyvinyl alcohol is 1:1, the organic solvent is methanol; the aldehyde is formaldehyde, the ratio of glyoxal is 1:1; the surfactant is a gemini quaternary ammonium salt type surfactant , And its structure is as follows:

[0050]

[0051] Among them, the synthesis reaction equation is:

[0052] RN(CH 2 CH 2 OH) 2 +BrCH 2 CH 2 Br→(CH 2 CH 2 OH) 2 R 1 N + CH 2 CH 2 N + R 2 (CH 2 CH 2 OH) 2

[0053] In the reaction formula, R is coconut oil base, representing a mixture of C8~C22 alkyl groups, R 1 And R 2 It is C8~C22 long-chain alkyl component, when R 1 And R 2 When the carbon number is the same, a symmetric gemini quaternary ammonium salt surfactant is generated, when R 1 And R 2 When the number of carbons is not the same, asymmetric gemini qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com