Municipal road and construction method thereof

A construction method and technology for municipal roads, applied in the direction of roads, roads, road repairs, etc., can solve problems such as uneven temperature deformation and temperature stress, short service life of roads, and fast surface heat dissipation, so as to prevent network cracks and prevent The effect of direct sunlight and reducing the rate of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

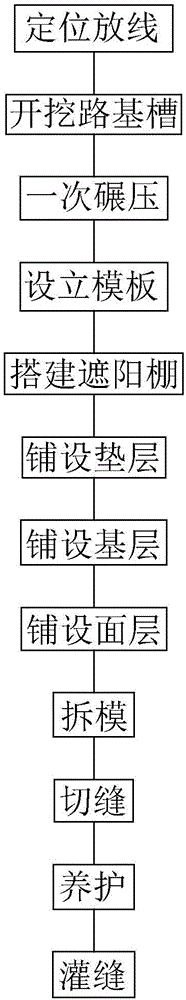

[0052] Embodiment 1: a kind of municipal road construction method, such as figure 1 , 2 and 3, including the following steps:

[0053] Step 1: Positioning and setting out

[0054] First determine the route of the municipal road, and determine the center line of the road, one pile for each 18-meter section of the straight line, one pile for every 4 meters for the curved section, and the outline of the road is formed by the above-mentioned piles;

[0055] Step 2: Excavating roadbed trenches

[0056] Drive the excavator into the outline, dig out the soil and stones in the outline to form the roadbed groove, and use the bulldozer to flatten the raised part of the bottom of the roadbed groove, and then use the grader to level the bottom of the roadbed groove ;

[0057] Step 3: Rolling once

[0058] Light vibration rolling is performed on the bottom of the subgrade groove by a vibratory roller. The vibration frequency of the vibratory roller is 25~30Hz, the amplitude is 1.4~2.0...

Embodiment 2

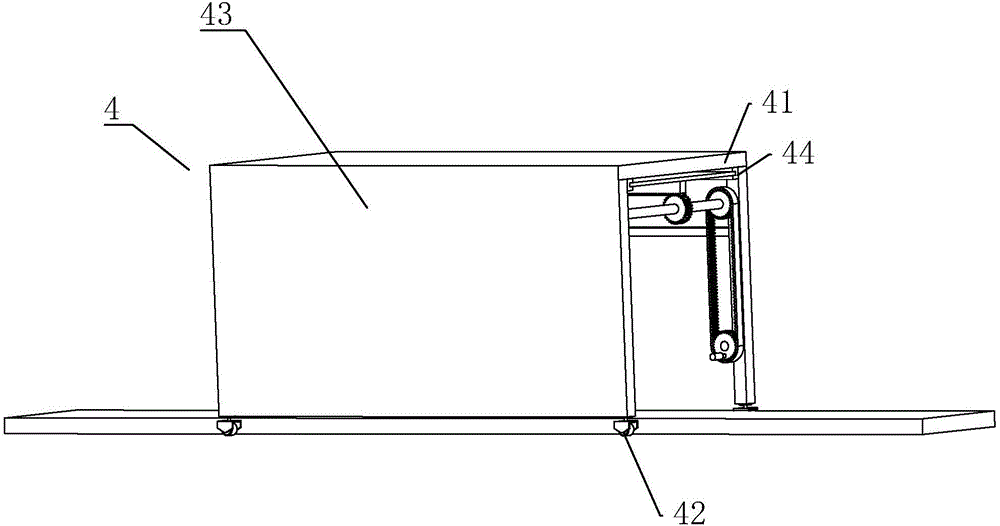

[0079] Embodiment 2: a kind of municipal road construction method, the difference with embodiment 1 is, as Figure 4 and 5 As shown, slide rails 44 parallel to each other are arranged on both sides of the downward facing side at the top of the bracket 41, and a sun visor 45 is clamped between the two slide rails 44, and the two sides of the sun visor 45 are respectively connected to Two slide rails 44 are slidingly connected, and a rotating roller 46 is also arranged below the sliding rail 44, and the two ends of the rotating roller 46 are connected with the two ends bearings of the support 41 respectively. The length direction of the road is vertical, and its slide rail 44 is parallel to the length direction of the road. On the roller 46, a driving gear 461 and a driven gear 462 are arranged. , the driving rack 451 meshes with the driving gear 461, and a driving gear 47 is rotatably connected to the bottom of the bracket 41. The driving gear 47 and the driven gear 462 are li...

Embodiment 3

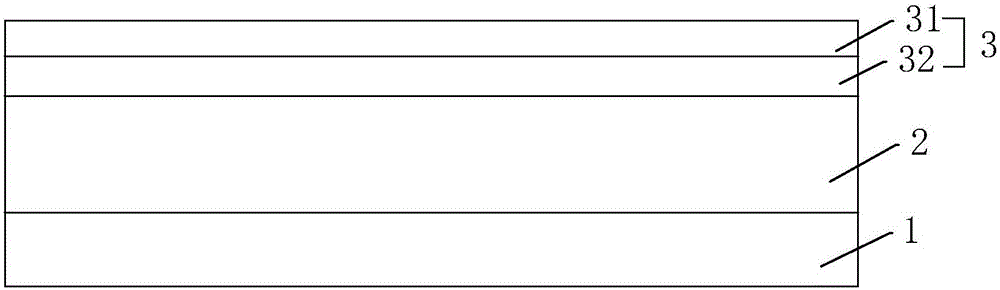

[0081] Embodiment 3: a kind of municipal road construction method, the difference with embodiment 2 is, as Figure 6 and 7 Shown, metal mesh 5 is to be that the threaded steel pipe 51 of diameter 1.5cm and the reinforcing bar 52 that diameter is 0.5cm are connected by binding wire 53 to form, when being placed on lower layer 32, threaded steel pipe 51 is perpendicular to the length direction of road, Steel bar one 52 is parallel to the length direction of the road; in the process of the upper layer 31 pouring and maintenance, it is connected to one end of the threaded steel pipe 51 through the water pipe 62, and the other end is also connected to the water storage tank 6 through the water pipe 62. One end is connected to a water pump 61 to circulate the water in the water storage tank 6 in the threaded steel pipe 51. After the maintenance is completed, the water pipe 62 is removed, and then a steel bar matching the inner diameter of the threaded steel pipe 51 is pierced in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com