Method for aerially aligning suspension type boiler drum after installation

A technology of boiler steam drum and hanging type, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems affecting the construction period and economic benefits, the radial horizontal deviation of the steam drum, the deformation of the steel structure girder, etc., and achieve saving Labor cost and labor time, simple operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

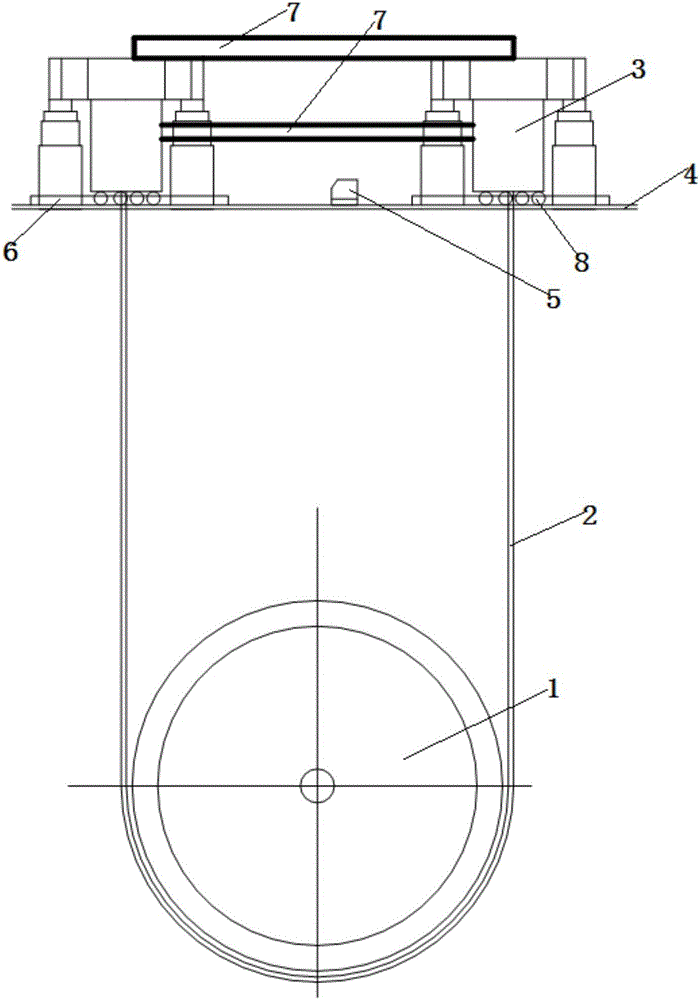

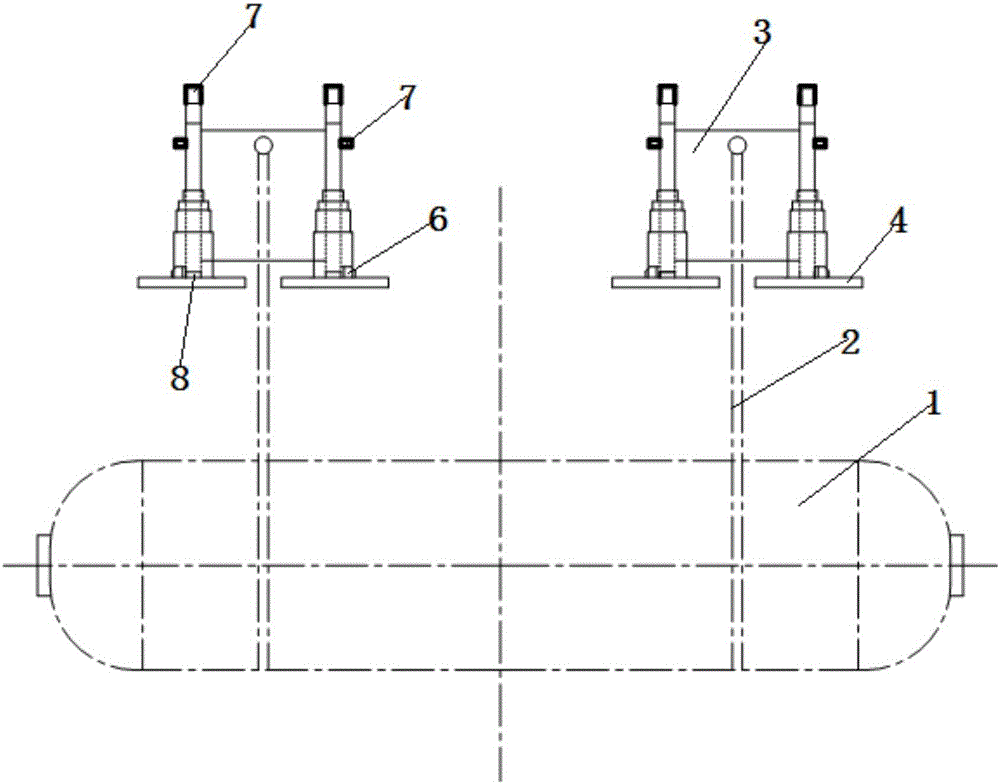

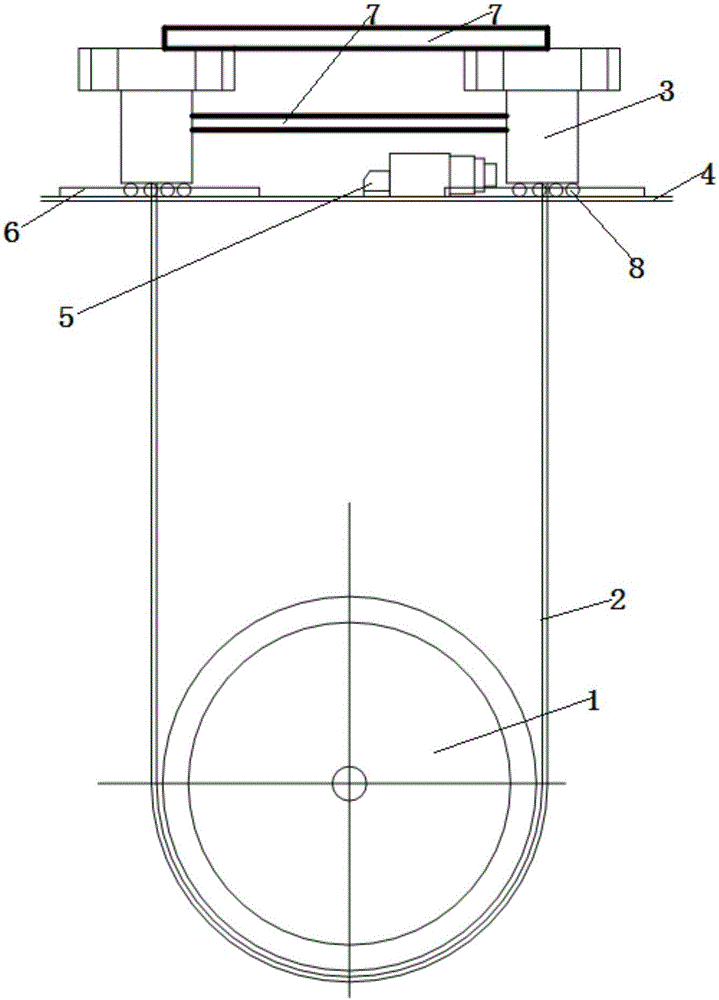

[0042] like Figure 1 to Figure 5 As shown, a method for aligning in the air after installation of a suspended boiler steam drum in this embodiment includes the following steps:

[0043] 1. Preparation

[0044] a. After the steam drum is installed and suspended on the four suspender bases 3 of the two steel structure girders 4 through two sets of U-shaped suspenders 2, the center of the steam drum 1 after installation is determined, based on the steel structure, and measured according to the drawing requirements The center line of the steam drum 1 is set out and marked. The suspender base 3 is suspended between the two large plate girders of the steel structure girder 4 in an H-shaped structure, and the vertical plate of the suspender base 3 is parallel to the plate girder. There are protrusions extending at both ends, which is convenient for the jack to lift the boom base 3 in the follow-up work;

[0045] b. A positioning stopper 5 is welded on the steel structure girder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com