Sleeve of full-casing and full-slewing drilling machine and method for removing barriers in front of cutter head of shield tunneling machine

A technology of full-rotary drilling rig and shield cutter head, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems that affect the construction progress of the project, it is not suitable for removing sleeve obstacles, and the construction period is long, so as to achieve simple construction. Fast and economical, avoiding the risk of piping quicksand, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

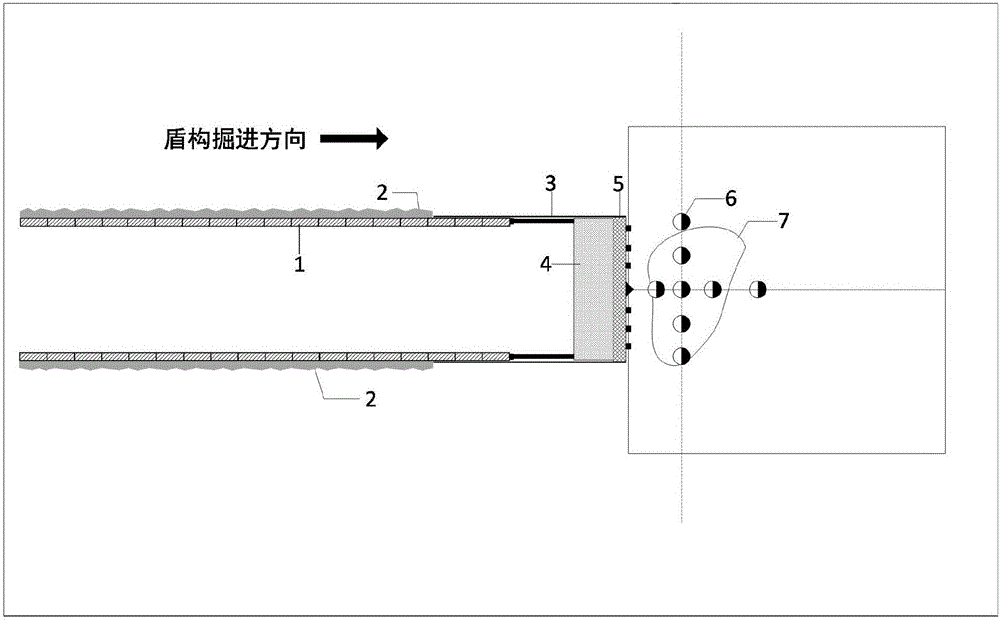

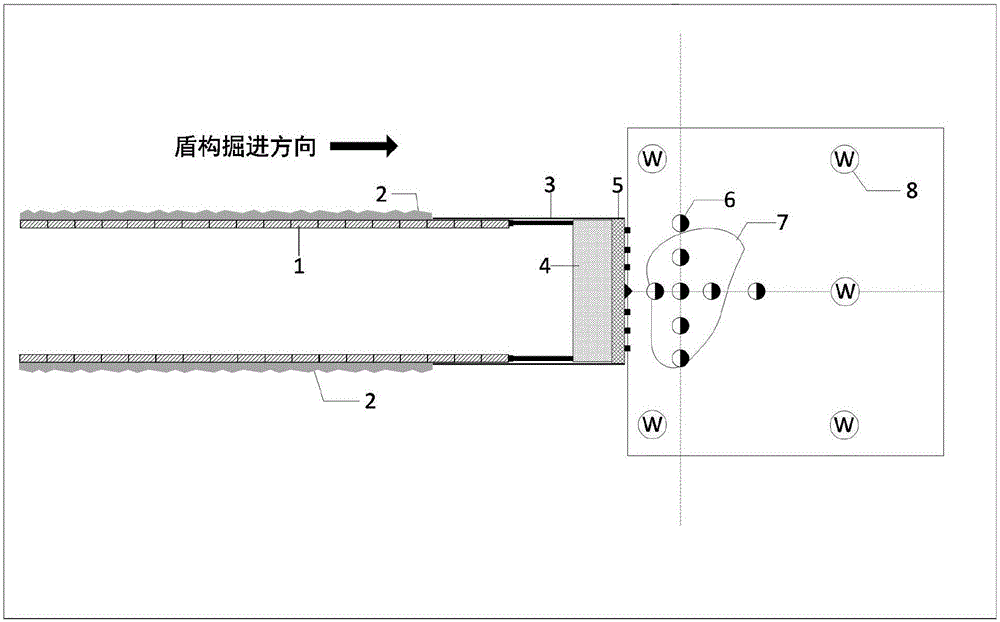

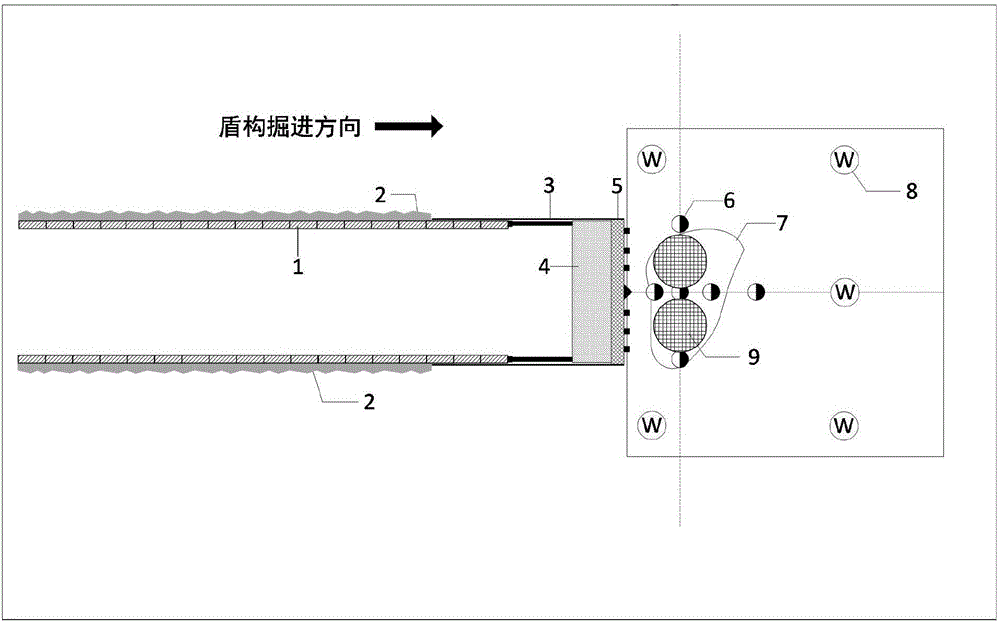

[0035] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] The shield machine 3 includes a shield machine shell, a shield cutter head 5, an earth ballast chamber 4, a screw conveyor, a propulsion mechanism and a segment structure 2, and the shield machine cutter head 5 is arranged at the front of the shield machine shell. The back of the shield cutterhead 5 is the soil ballast 4, the bottom of the soil ballast 4 is connected with the screw conveyor, and the soil cut by the shield cutterhead 5 enters through the holes distributed on the shield cutterhead 5. In the soil ballast chamber 4, it is transported to the outside of the shield machine casing through the screw conveyor located at the excavation port at the lower part of the soil ballast chamber 4; the shield machine casing is surrounded by propulsion oil cylinders, and the props installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com