Zinc-base alloy bearing based on solid lubricating agent

A solid lubricant and zinc-based alloy technology, applied in the field of alloy casting products, can solve the problems of shortened service life, poor water resistance, fast deterioration of solid lubricants, etc., and achieve long service life, easy maintenance and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

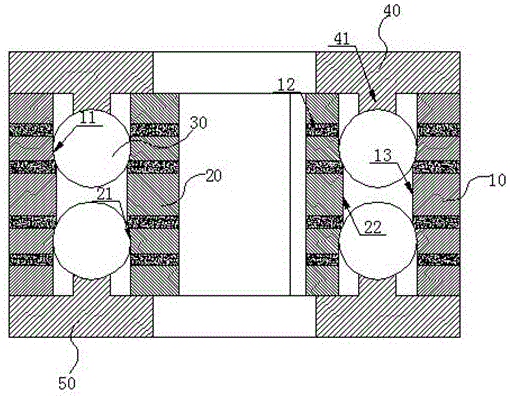

[0013] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0014] Such as figure 1 As shown, a zinc-based alloy bearing based on a solid lubricant includes a self-lubricating bearing outer ring 10 and a self-lubricating bearing inner ring 20, and the self-lubricating bearing outer ring 10 and the self-lubricating bearing inner ring 20 are coaxially fitted set, and a self-lubricating bearing ball 30 is arranged between the self-lubricating bearing outer ring 10 and the self-lubricating bearing inner ring 20, the axial direction of the self-lubricating bearing outer ring 10 and the self-lubricating bearing inner ring 20 Both ends are also provided with a first self-lubricating bearing packaging cover 40 and a second self-lubricating bearing packaging cover 50 respectively; Position installation groove 11, the outer surface of the self-lubricating bearing inner ring 20 is provided with an inner ring ball limit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com