Method and device for online removing refinery plant FCC device waste heat boiler scale

A waste heat boiler and refinery technology, which is applied in separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problem that ammonium hydrogen sulfate is not suitable for positive pressure waste heat boilers in refineries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

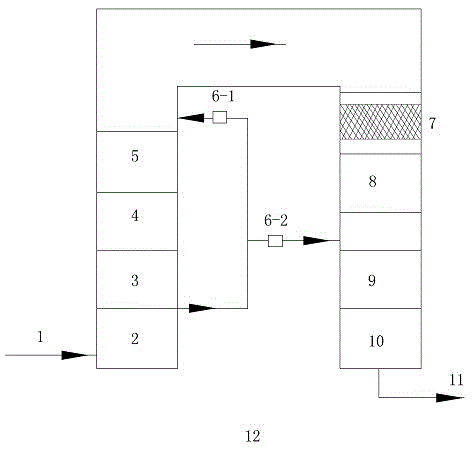

Image

Examples

Embodiment 1

[0040] Parameters of a CO waste heat boiler in a refinery: regeneration flue gas flow rate 160,000 Nm 3 / h, temperature 510°C, CO content 6% (v / v). Its design thermal efficiency is 77%, the temperature of the regenerated flue gas after combustion in the furnace is 813°C, the excess air coefficient is 1.2, the CO content is 3% (v / v), and the dust concentration is 0.7g / Nm 3 , and contain Cu, Fe, Ni, V, etc. that cause scaling of ammonium bisulfate in the waste heat boiler.

[0041] The waste heat boiler is added with a denitrification unit for denitrification. The denitrification reaction temperature is 308°C. After ammonia injection, the NOx is reduced from 800mg / Nm 3 down to 200mg / Nm 3 After 5 months of operation, due to the excessive addition of ammonia, the pressure drop of the advanced economizer of the boiler has increased from 600Pa to 1800Pa, and the exhaust gas temperature has increased from 175°C to 195°C. The reason for the analysis is that the economizer generates ...

Embodiment 2

[0044] Parameters of a CO waste heat boiler in a refinery: regeneration flue gas flow rate 140,000 Nm 3 / h, temperature 546°C, CO content 6.3% (v / v). Its design thermal efficiency is 75%, the temperature of the regenerated flue gas after combustion in the furnace is 800°C, the excess air coefficient is 1.3, the CO content is 3.2% (v / v), and the dust concentration is 0.6g / Nm 3 , and contain Cu, Fe, Ni, V, etc. that cause scaling of ammonium bisulfate in the waste heat boiler.

[0045] The waste heat boiler is added with a denitrification unit for denitrification. The denitrification reaction temperature is 313°C. After ammonia injection, the NOx is reduced from 600mg / Nm 3 down to 150mg / Nm 3 After 5 months of operation, due to the excessive addition of ammonia, the pressure drop of the advanced economizer of the boiler has increased from 800Pa to 1400Pa, and the exhaust gas temperature has increased from 169°C to 199°C. The reason for the analysis is that the economizer genera...

Embodiment 3

[0048] Parameters of a CO waste heat boiler in a refinery: regeneration flue gas flow rate 100,000 Nm 3 / h, temperature 532°C, CO content 6.2% (v / v). Its design thermal efficiency is 75%, the temperature of the regenerated flue gas after burning in the furnace is 808°C, the excess air coefficient is 1.4, the CO content is 3.4% (v / v), and the dust concentration is 0.8g / Nm 3 , and contain Cu, Fe, Ni, V, etc. that cause scaling of ammonium bisulfate in the waste heat boiler.

[0049] The waste heat boiler is added with a denitrification unit for denitrification. The denitrification reaction temperature is 309°C. After ammonia injection, the NOx is reduced from 700mg / Nm 3 down to 100mg / Nm 3 After 5 months of operation, due to the excessive addition of ammonia, the pressure drop of the advanced economizer of the boiler has increased from 650Pa to 1700Pa, and the exhaust gas temperature has increased from 166°C to 210°C. The reason for the analysis is that the economizer generates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com