No-smoke environment-friendly and energy-saving funnel

An environment-friendly, energy-saving and chimney technology, which is applied in exhaust gas devices, combustion product treatment, combustion methods, etc., can solve the problems of energy loss, short service life, and a large amount of white mist, so as to ensure airtightness, thoroughness, and convenience Use and maintenance, reduce the effect of environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

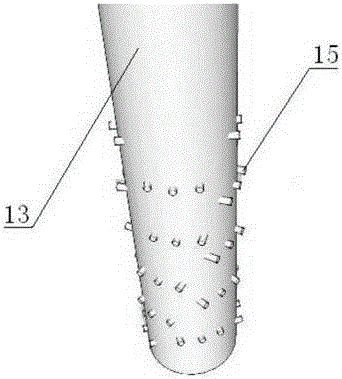

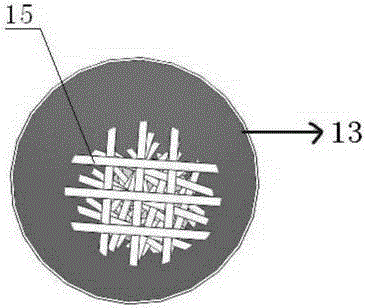

[0034]The boiler flue gas passes through the smoke and dust collector 3 along the exhaust pipe 2, and then passes through the gas-eliminating sewage tank 4 and the gas-eliminating water purification tank 6, and then enters the air from the chimney 7; through the heat-insulated pipe 13, the heat contained in the boiler flue gas is guaranteed not to be lost , and further use the hot water pipe 15 to absorb most of the heat in the boiler flue gas; the heat carrier is injected into the hot water pipe 15 through the cold water inlet pipe 16 to absorb heat, and the heated heat carrier flows out from the hot water outlet pipe 14 to supply the surrounding residents use.

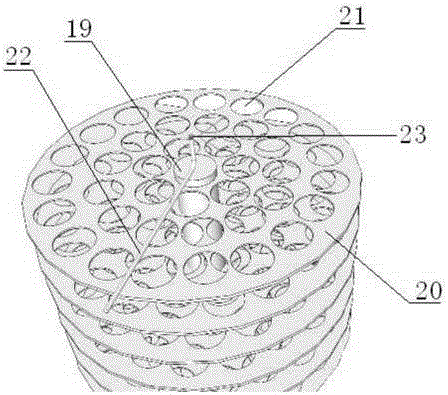

[0035] Reduce the flow velocity of flue gas through gradually enlarged smoke exhaust pipes, and then spray lime water through spraying water inlet pipe 22 and smoke elimination sprayer 23 to eliminate smoke, desulfurize and purify water; at the same time, the sprayed water mist will condense with smoke and dust into s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com