A deep recovery device for boiler flue gas waste heat

A boiler flue gas and recovery device technology, applied in the energy field, can solve the problems of lowering combustion temperature, lowering exhaust gas temperature, and unable to increase air temperature and humidity, so as to reduce combustion temperature, increase dew point temperature, and solve the problem of hard to find cold source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

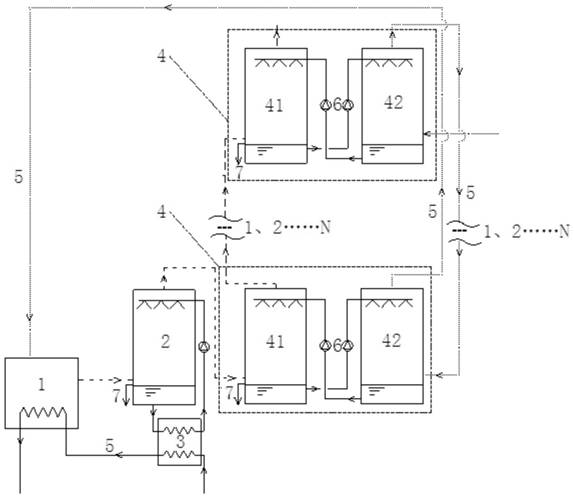

[0026] like figure 1 As shown, the boiler flue gas waste heat deep recovery device of the present invention includes a boiler 1, a steam-water heat exchanger 2, a water-water heat exchanger 3, an N-level flue gas-air total heat heat exchange unit 4, a number of pipes 5 , a number of water pumps 6 and a number of overflow pipes 7, each stage of the flue gas-air total heat exchange unit 4 includes a flue gas-water heat exchanger 41 and an air-water heat exchanger 42, where N≥2.

[0027]The present invention takes the two-stage flue gas-air total heat exchange unit 4 as an example to describe the boiler flue gas waste heat deep recovery device of the present invention in detail:

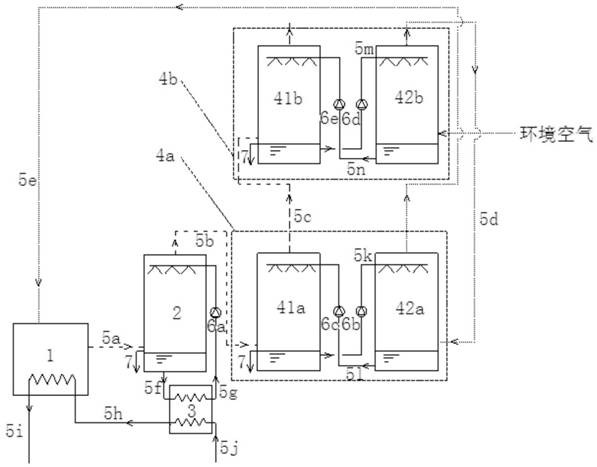

[0028] like figure 2 As shown, the flue gas-air total heat exchange unit 4 of this embodiment includes a high temperature section flue gas-air total heat heat exchange unit 4a and a low temperature section flue gas-air total heat heat exchange unit 4b, wherein the high temperature section The flue ga...

Embodiment 2

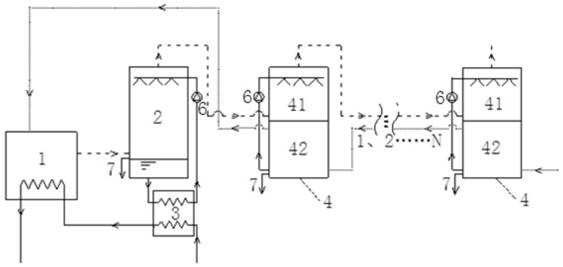

[0037] like Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. The difference is that this embodiment replaces the N-stage flue gas-air total heat exchange unit 4 of Embodiment 1 with a flue gas-water heat exchanger N-1 liquid distributors 8 are arranged at intervals from bottom to top. Correspondingly, N-1 water receiving trays 9 are arranged at intervals from top to bottom in an air-water heat exchanger 42. The water inlets are correspondingly connected to the water inlets of each liquid distributor 8, the bottom water outlet of the flue gas-water heat exchanger 41 is connected to the top water inlet of the air-water heat exchanger 42, and the bottom water outlet of the air-water heat exchanger 42 is connected The top water inlet of the flue gas-water heat exchanger 41 .

[0038] The present invention takes a liquid distributor 8 and a water receiving tray 9 as examples to describe the boiler flue gas waste heat deep recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com