Fuel cell bipolar plate with internal water diversion/internal humidification structure

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems that the humidification effect depends on the distribution density of pores, the conductivity is greatly affected, and the porous plate is not connected, so as to increase the reliability of materials. Select range, enhance effect, reduce energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

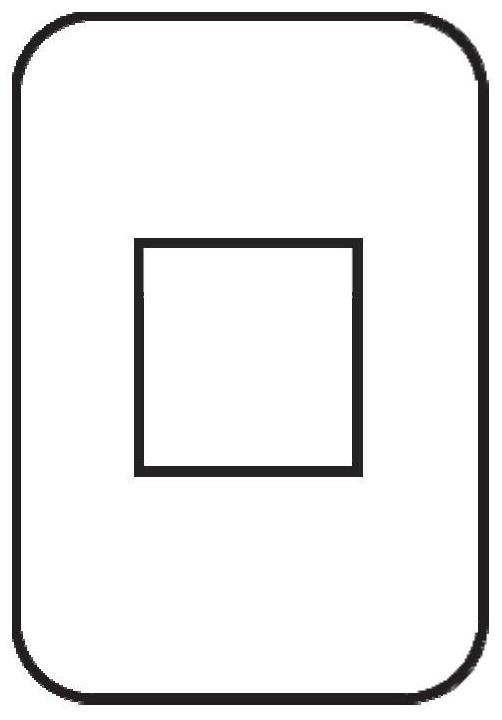

[0044] A fuel cell bipolar plate with an internal water separation / internal humidification structure, the bipolar plate is provided with an oxygen pole plate 10, a water flow field plate 6 and a hydrogen pole plate 11 in sequence from one side to the other side; Described oxygen pole plate 10 is the combination of microporous stainless steel dense pattern net and the conductive solid stainless steel plate that contains 1 through hole (such as figure 1 shown), the through hole is sealed around the hole with a hydrophilic polypropylene film having the function of conducting water and blocking gas; the water flow field plate 6 is a conductive graphite plate containing a water flow field, and the hydrogen plate 11 is a conductive graphite plate containing a gas flow field. Solid stainless steel plate, bipolar plate decomposition structure such as Figure 6 shown.

[0045] Using this bipolar plate, assemble a 1kW stack, the stack structure is as follows Figure 7 shown. Test wi...

Embodiment 2

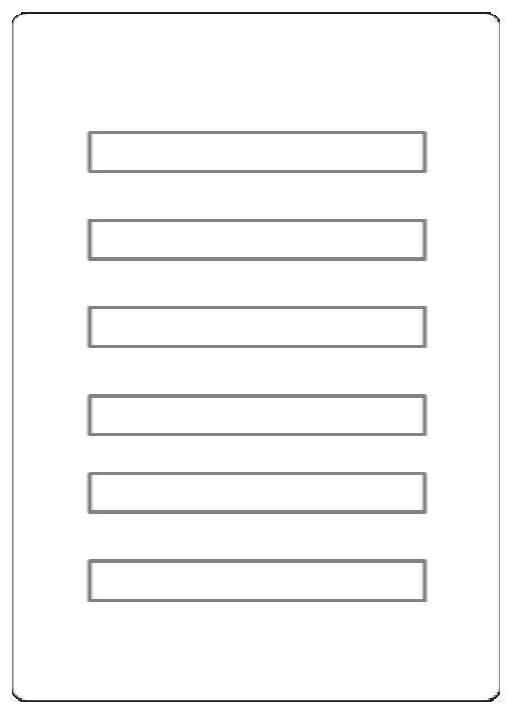

[0047] The conductive solid plate between the oxygen flow field plate and the water flow field plate is a solid titanium plate with 6 through holes (such as figure 2 shown), other structures are the same as in Example 1, and a fuel cell bipolar plate with internal water separation / internal humidification functions is obtained.

Embodiment 3

[0049] The conductive solid plate between the oxygen flow field plate and the water flow field plate is a solid stainless steel plate (such as image 3 shown), other structures are the same as in Example 1, and a fuel cell bipolar plate with internal water separation / internal humidification functions is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com